A double swirl lean premix nozzle and its application

A premixed nozzle, double swirl technology, applied in combustion methods, lighting and heating equipment, continuous combustion chambers, etc., can solve the problem of high pressure loss in the combustion chamber, reduce emissions, solve high pressure loss, and reduce local high temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

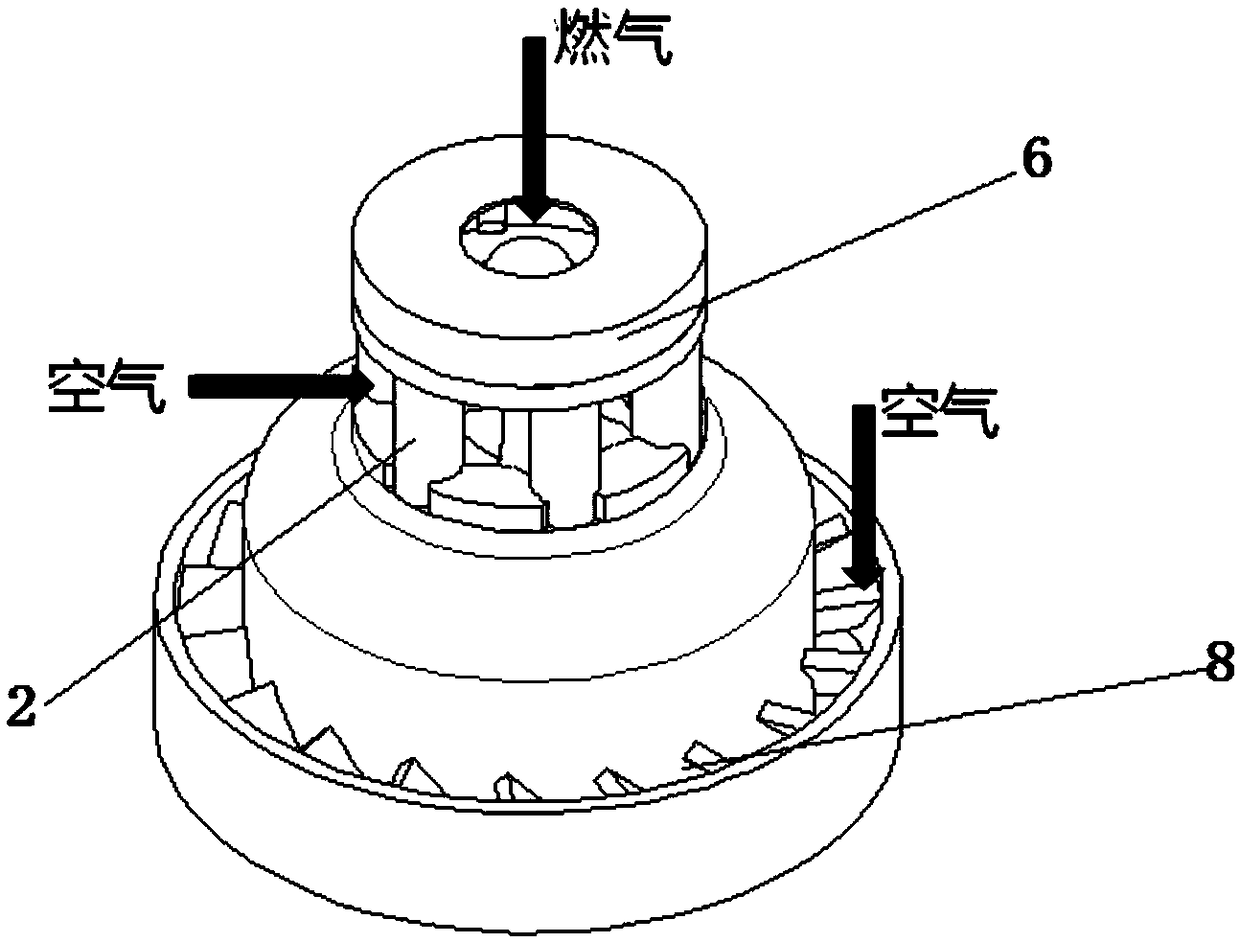

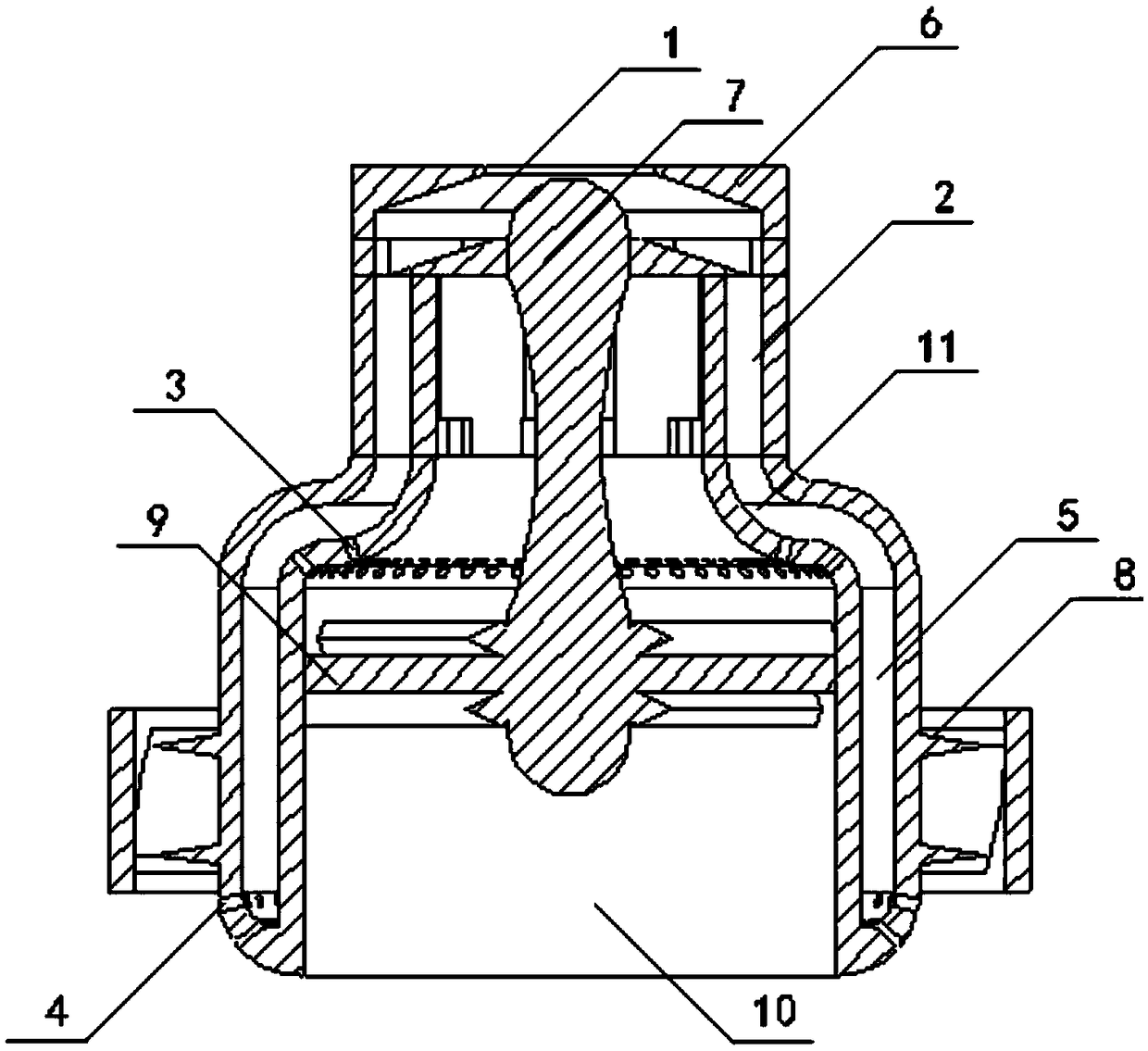

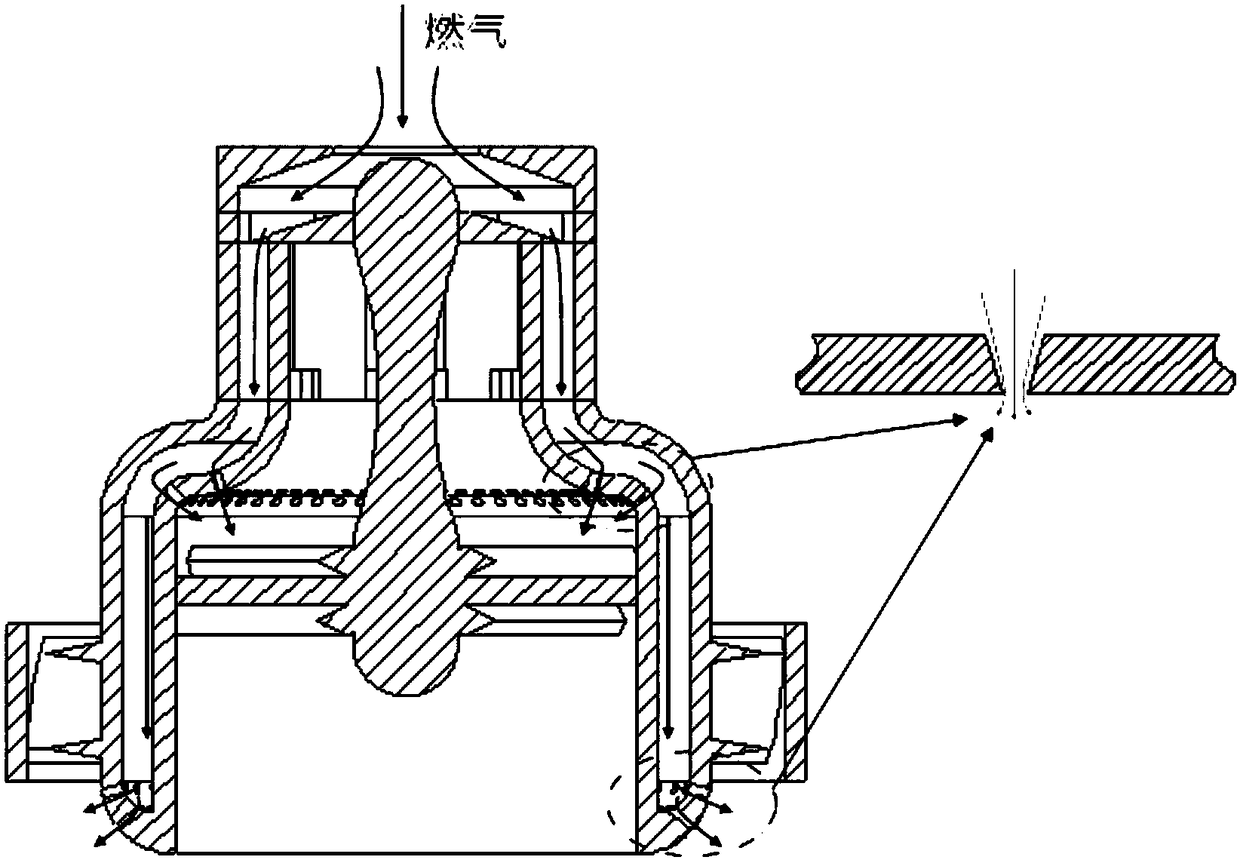

[0034] like Figure 1-4 As shown, a double-swirl lean premixing nozzle includes a gas splitting chamber cap 6, a gas splitting chamber 1 set on the top of the gas splitting chamber cap 6, a central spindle 7 suspended below the gas splitting chamber 1, The lean premix chamber 10 located at the bottom of the central spindle body 7 and the annular guide unit connecting the gas split chamber 1 with the lean premix chamber 10 and the outside air, the nozzle also includes a coaxial inner axial swirler 9 and The outer axial swirler 8 and the inner axial swirler 9 are arranged in the lean premix chamber 10, and the inner diameter of the inner axial swirler 9 is connected with the central spindle body 7, and the outer diameter is connected with the annular gas chamber 5, The inner diameter of the outer axial swirler 8 is connected with the outer wall surface of the annular gas chamber 5 . In the working state, after the gas is divided by the gas distribution chamber 1, a part of it e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com