Hollow shaft structure of multi-layer furnace as well as dismounting tool and dismounting method for rabble arm and rabble teeth

A technology for dismantling tools and hollow shafts, which is applied to combustion methods, manufacturing tools, incinerators, etc., can solve problems such as small adjustment range, high labor intensity, and high dust content in flue gas from the furnace, and achieve a large speed adjustment range and easy maintenance and replacement. Convenience and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

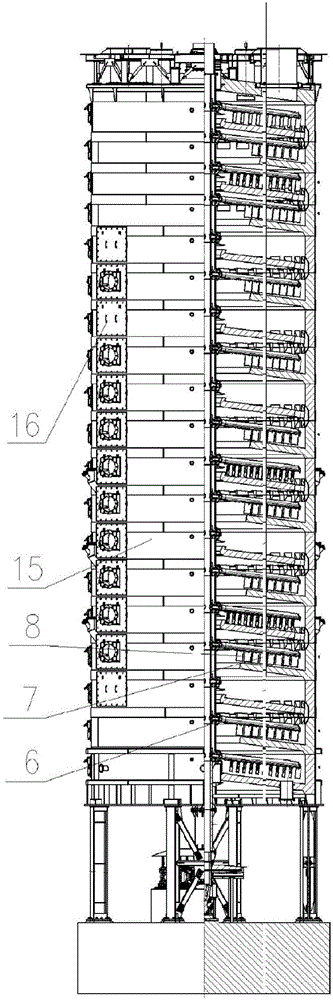

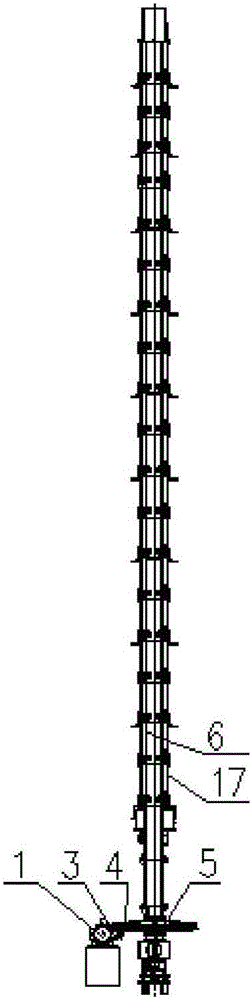

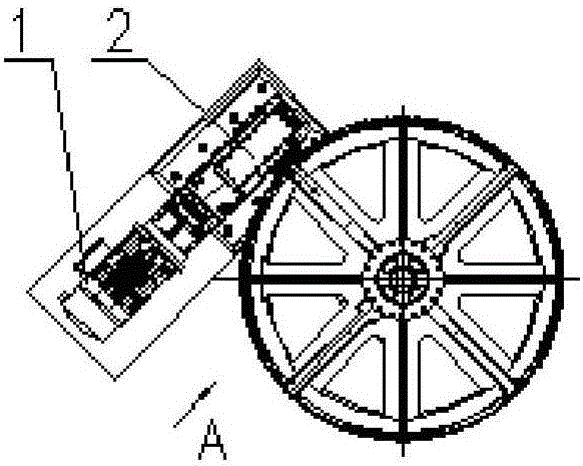

[0029] like Figure 1-Figure 5 As shown, a hollow shaft structure of a multi-layer furnace includes a hollow shaft 6, a rake arm 7, and rake teeth 8. The rake arm 7 is connected to the hollow shaft 6 through a rake arm pin 9, and the rake teeth 8 are installed on the slide at the bottom of the rake arm 7. On the road, it is positioned by the rake tooth pin 10 at the end of the rake arm 7; it also includes a frequency conversion speed regulation motor 1, a reducer 2, a small bevel gear 3, a large bevel gear 4, and the bottom shaft 5 of the hollow shaft 6 is fixed to the large bevel gear 4 Connected, the large bevel gear 4 and the small bevel gear 3 mesh with each other, and the small bevel gear 3 is connected to the drive shaft of the variable frequency speed regulating motor 1 through the reducer 2.

[0030] See figure 1 , is a structural schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com