Metal belt drive reliability compensation control device and control method of continuously variable transmission

A technology of continuously variable transmission and compensation control, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve problems such as sudden slipping and ablation, and achieve the effect of metal belt transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

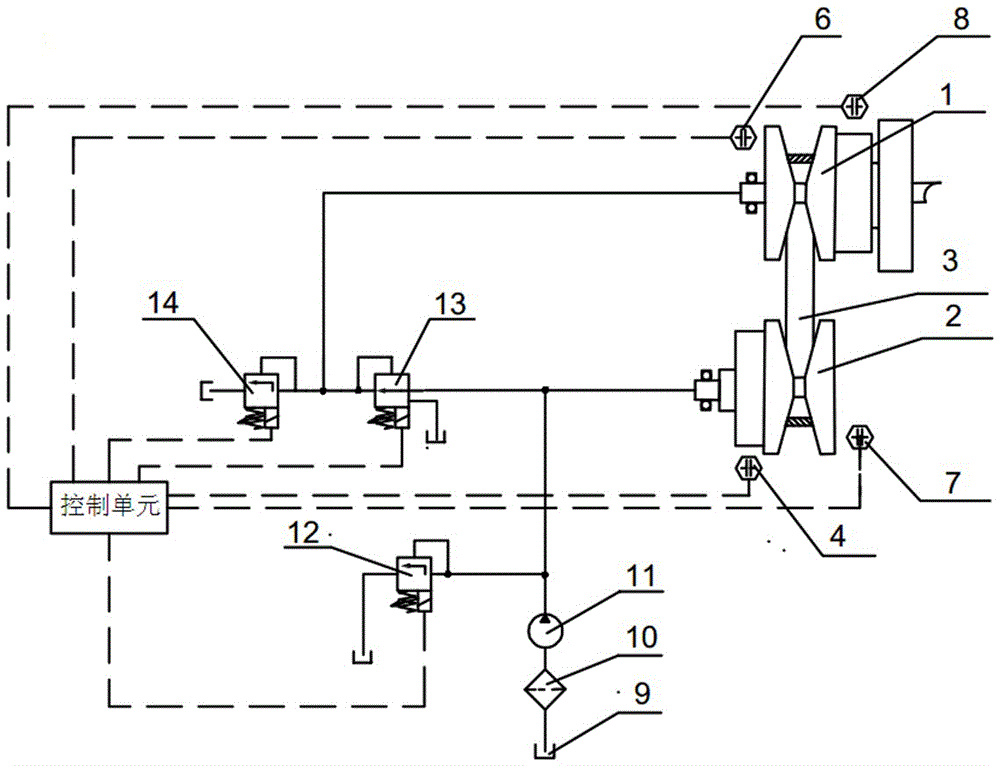

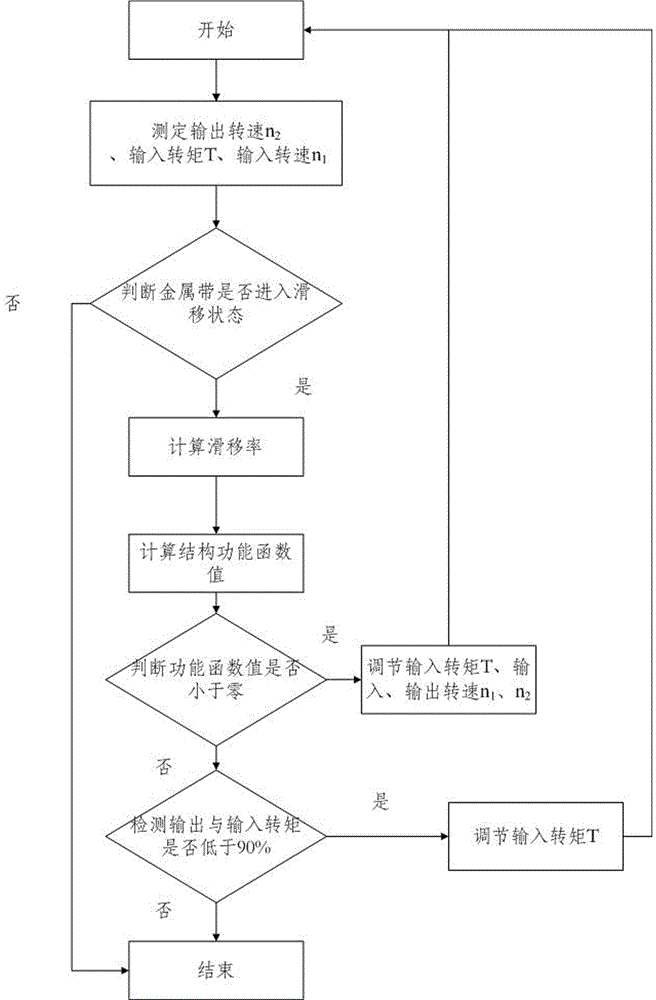

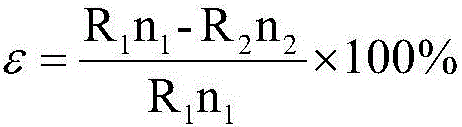

[0025] Such as figure 1 As shown, a metal belt transmission reliability compensation control device for a continuously variable transmission, including a driving wheel 1, a driven wheel 2, a metal belt 3, an oil pump 11, a speed ratio control proportional overflow valve 13, and a clamping force control proportional pressure reducing valve 12. Output speed control proportional relief valve 14 and control unit, the metal belt 3 is connected between the driving wheel 1 and the driven wheel 2, the driving wheel 1 is provided with a first speed sensor 6, and the driving wheel 1 inputs A first torque sensor 8 is provided on the shaft, a second speed sensor 7 is provided on the driven wheel 2, a second torque sensor 4 is provided on the output shaft of the driven wheel 2, and the inlet of the oil pump 11 passes through a filter 10 Afterwards, it is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com