Anticollision guide sleeve of drill bit of large drilling machine

A technology for guide sleeves and drilling rigs, which is applied in drilling tools, drilling equipment, earthwork drilling and mining, etc. It can solve problems such as bracket deformation and bracket scrapping, and achieve the effects of avoiding collisions, increasing service life, and reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

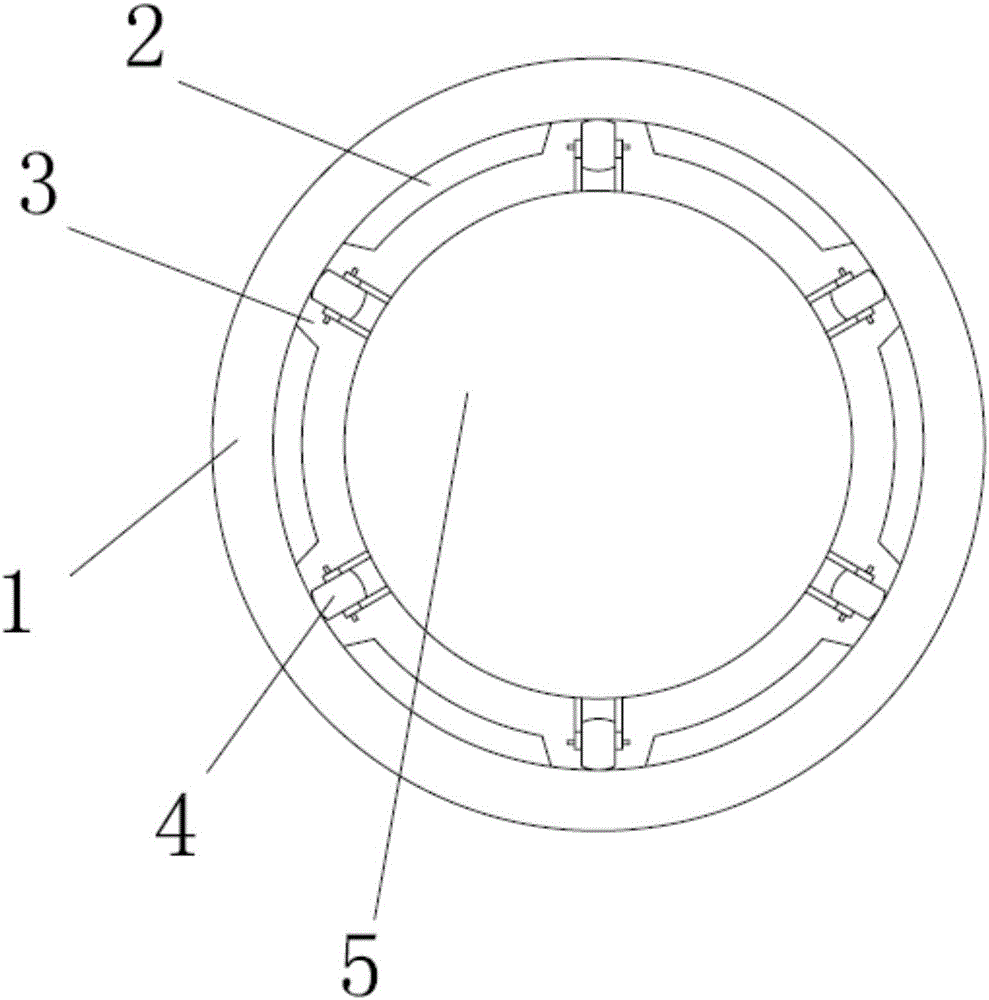

[0017] When just starting to dock the drill bit with the positioning bracket, insert the drum-shaped stabilizer 5 with the drill bit into the positioning bracket equipped with the guide sleeve 1, and the guide roller 4 on the drum-shaped stabilizer 5 runs along the rubber backing ring 2 The guide groove 3 slides so that the drill bit can enter the bracket smoothly. Since the inner ring of the guide sleeve 1 adopts the rubber backing ring 2, the impact force when the drill bit collides with the guide sleeve 1 can be effectively reduced.

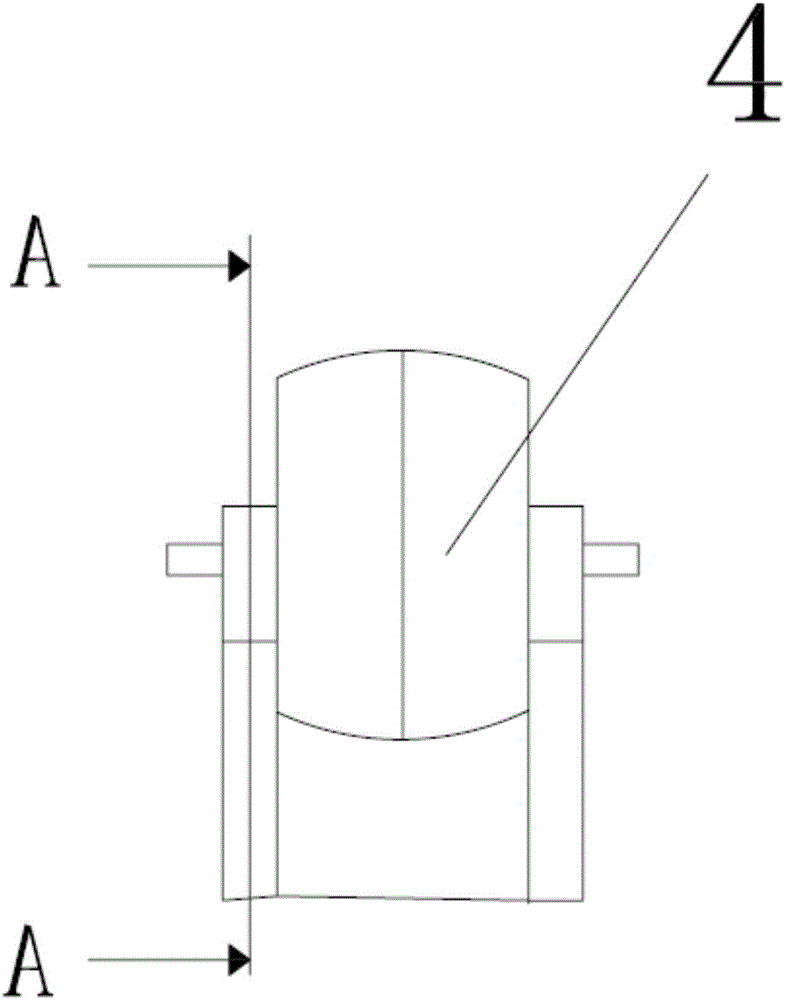

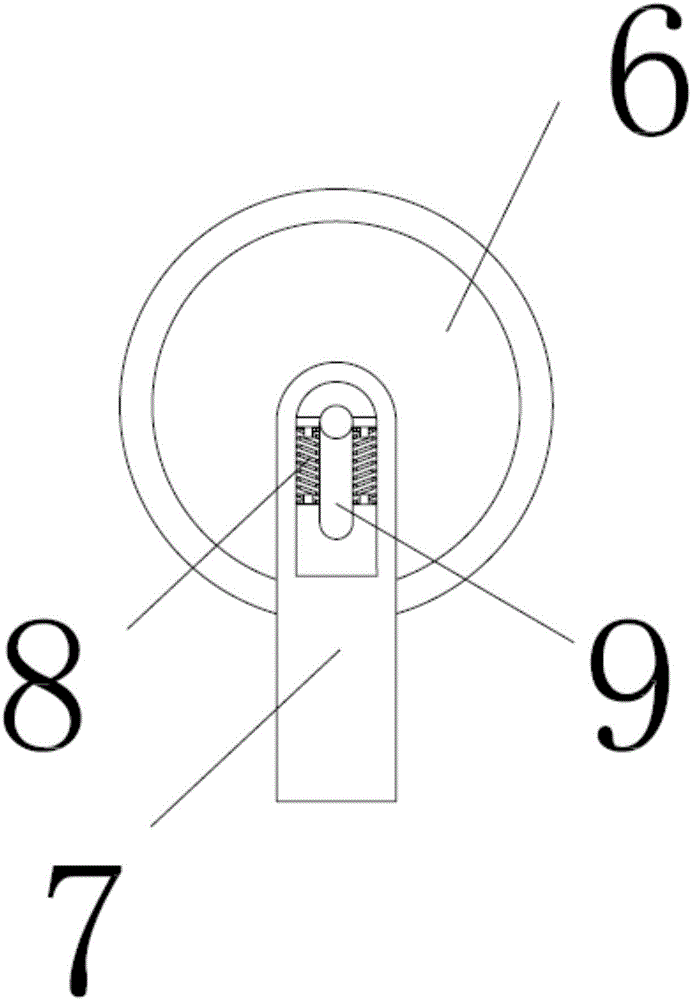

[0018] A straight guide rail through hole 9 is arranged on the bracket plate 7 of the guide roller 4, so that the rotating shaft of the guide roller 4 can slide in the straight guide rail through hole 9, and a return spring 8 is installed in the bracket plate 7 to reduce the impact of the guide roller 4 itself The force can effectively protect the positioning bracket and the guide sleeve 1, so that the service life of the positioning bracket is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com