A connection structure of prefabricated bridge piers and prefabricated caps and its butt joint construction method

A technology of prefabricated caps and piers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of prolonging the construction period of bridges, achieve the effects of improving durability, reducing workload, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

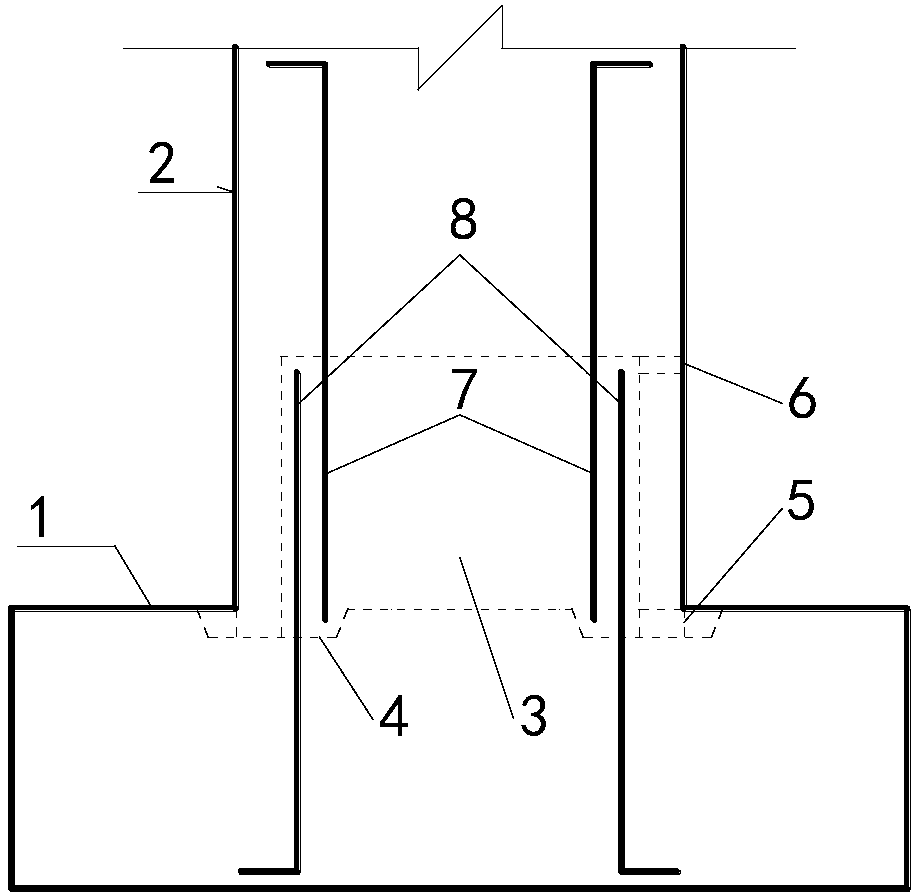

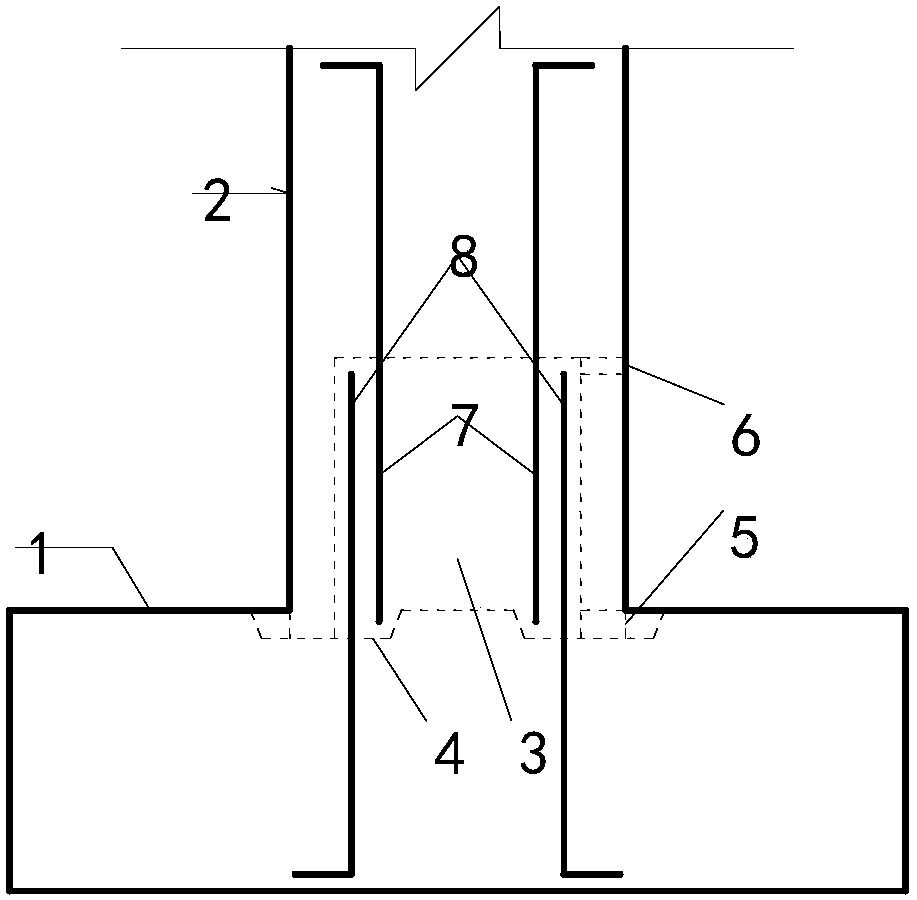

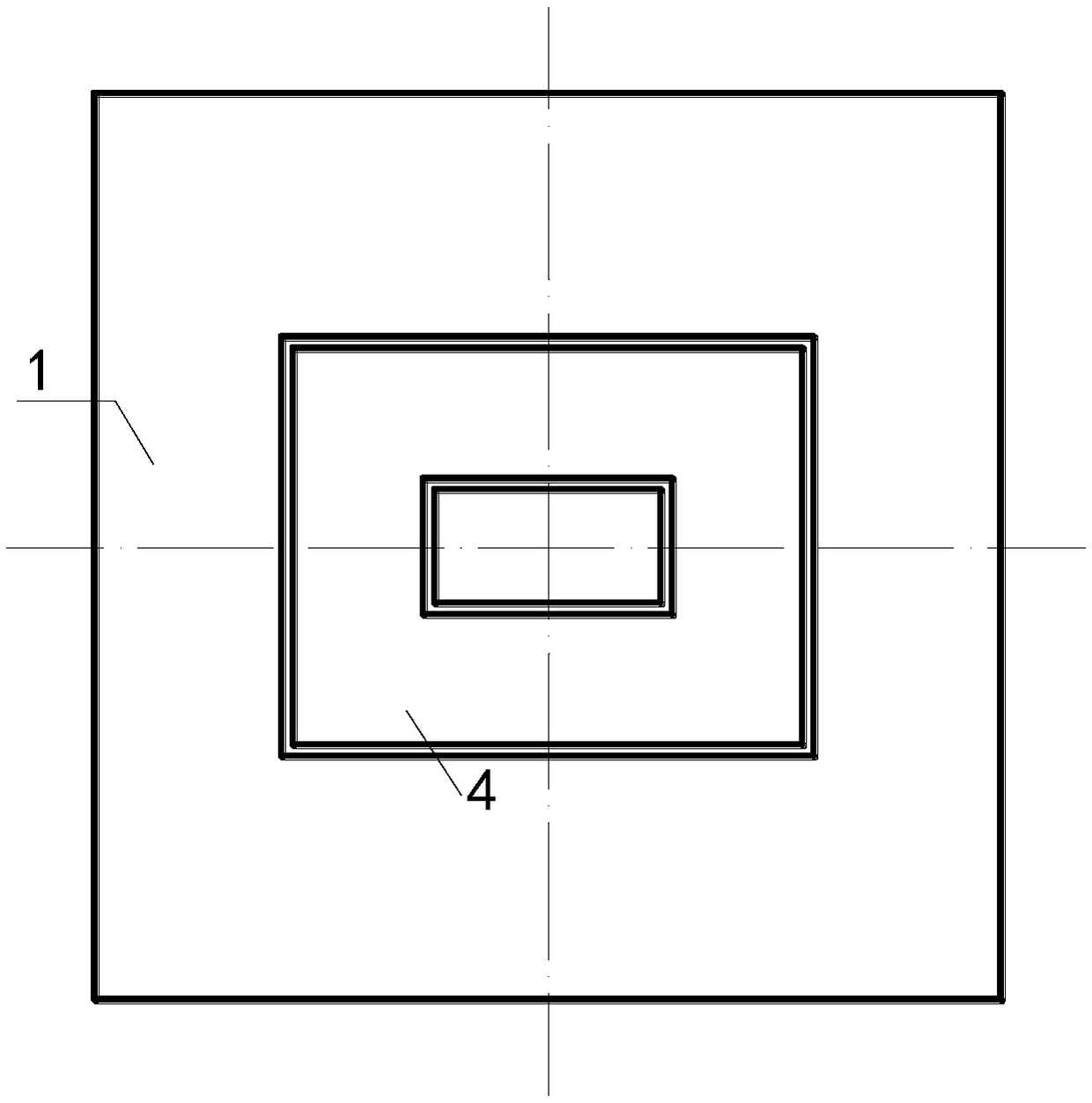

[0028] A connection structure between a prefabricated cap and a prefabricated bridge pier, characterized in that the pier includes a prefabricated pier body 2 and a post-cast belt 3 of a hollow section at the bottom of the pier body, a groove 4 is arranged on the top of the prefabricated cap 1, and a hollow section at the bottom of the pier body The post-cast belt 3 has the vertically protruding steel bars 8 of the prefabricated cap and the vertically protruding steel bars 7 of the prefabricated pier.

[0029] Taking the single-column pier as an example, the structural composition of the present invention is shown in Figure 1 (wherein Figure 1a It is the connection construction elevation of the prefabricated pier and cap, Figure 1b for Figure 1a side view), consists of the following eight parts: 1- prefabricated cap; 2- prefabricated bridge pier; 3- post-casting strip of hollow section at the bottom of prefabricated bridge pier; 4- groove at the top of prefabricated bridge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com