Accurately adjustable track structure of stamping, coal charging and coke pushing car

A technology for precise adjustment and pushing of coke carts, applied in coke ovens, charging devices, unloading devices, etc., can solve problems such as uneven force on the track, difficulty in adjusting the track adjustment accuracy to meet the requirements of track accuracy and performance, and broken rails , to achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

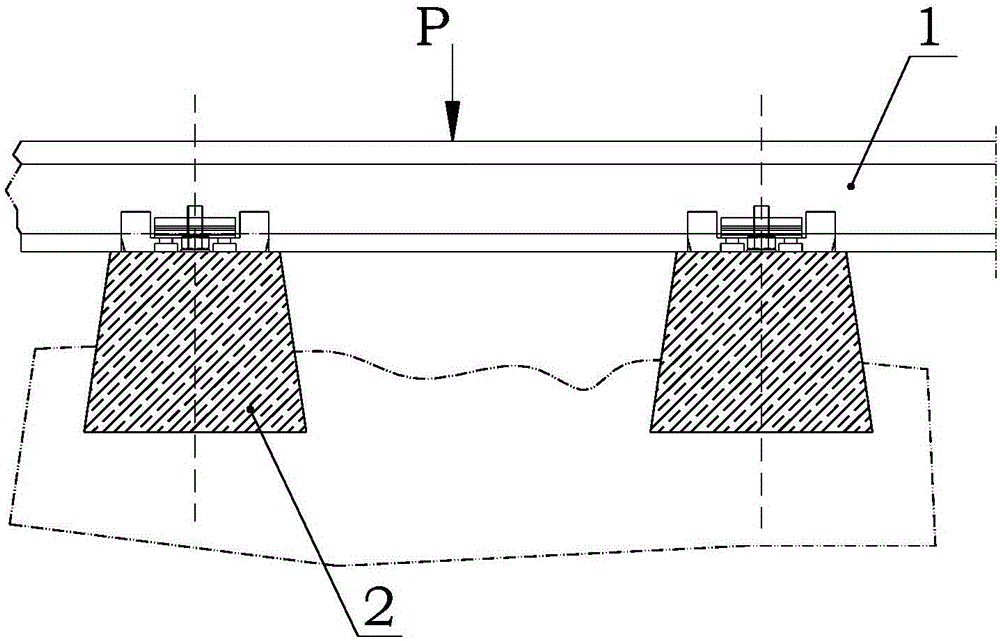

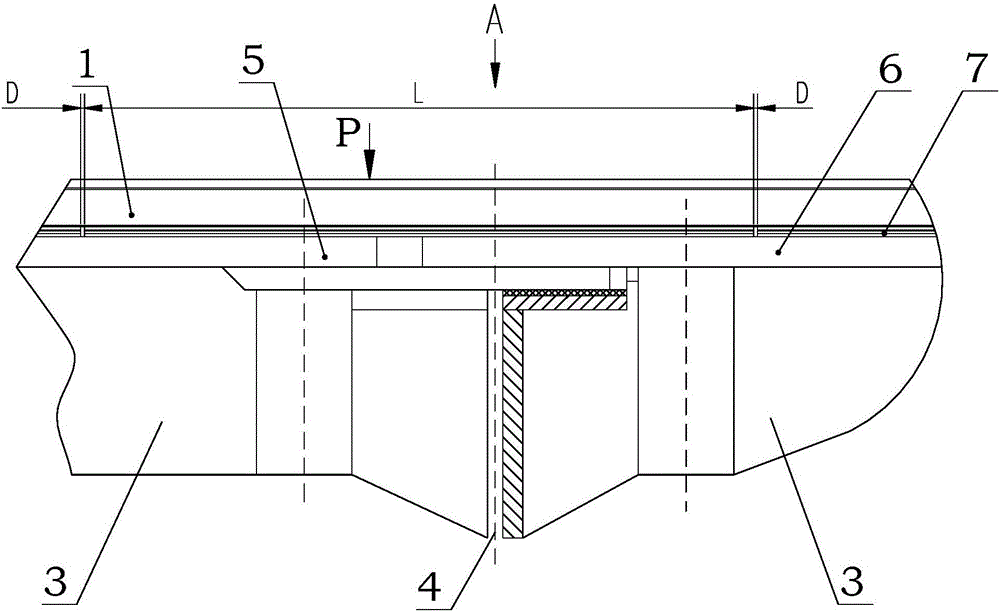

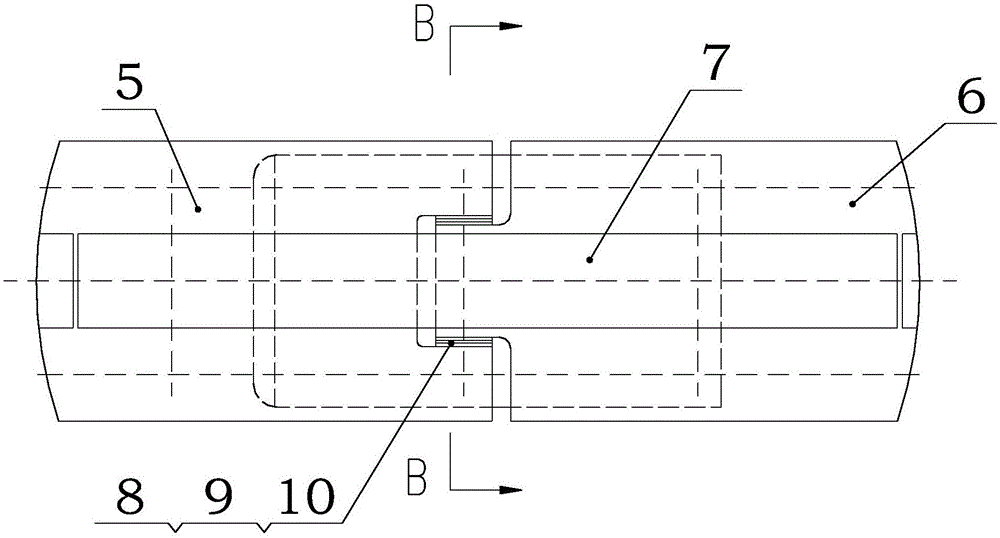

[0018] Such as Figure 2-Figure 4 As shown, the track structure of a precisely adjustable tamping, coal charging, and coke pushing vehicle described in the present invention includes a track foundation, a rail adjustment backing plate group 7, a steel rail 1 and a base plate connection adjustment backing plate group; the track foundation Corresponding to the carbonization chamber of the coke oven, there are multiple solidification sections 3, expansion joints 4 are respectively provided between adjacent solidification sections 3, foundation plates 5, 6 are provided on each solidification section 3; The structure is plugged in, and the connection joints on both sides of the concave-convex structure are respectively provided with the base plate connection adjustment backing plate group; the rail 1 is fixed on the foundation plates 5, 6, and the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com