Steam foam compound flooding composition and preparation method thereof

A composition and composite flooding technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of small foam sweep coefficient and poor salt tolerance of foam agents, and achieve improved salt tolerance and increased adsorption capacity. Great and good salt tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

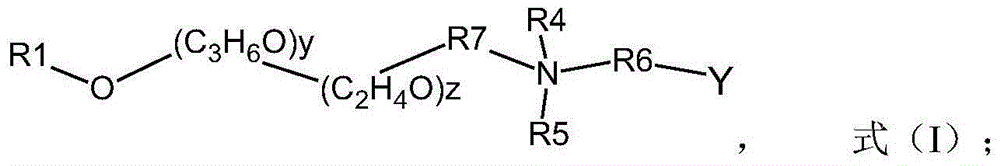

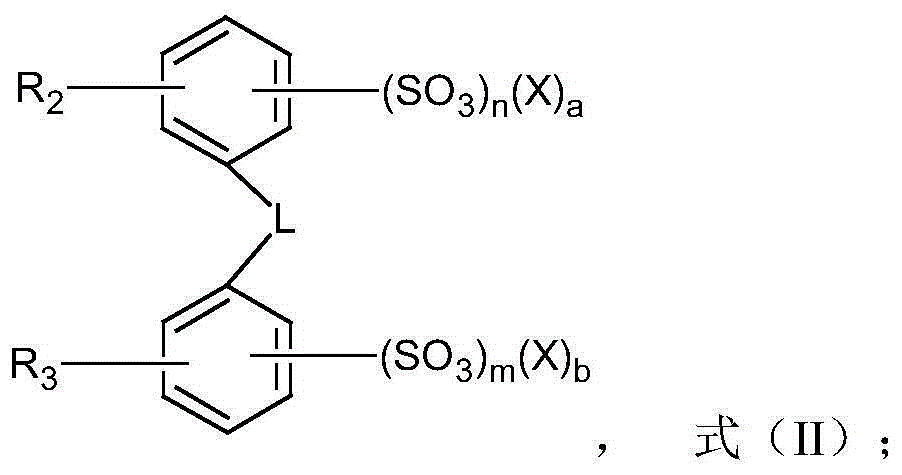

Method used

Image

Examples

Embodiment 1

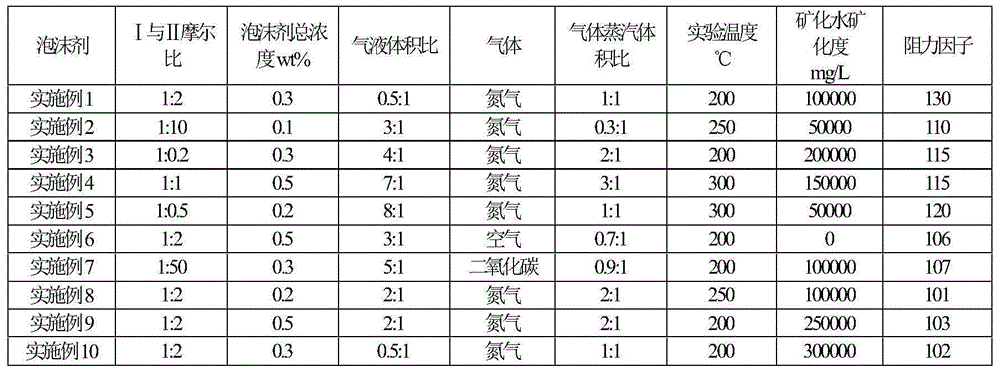

[0038]The long-chain polyether nitrogen-containing compound and the long-chain diaryl sulfonate are dissolved in water with a salinity of 100,000 mg / L according to the molar ratio of 1:2, and the total mass fraction of the foaming agent is 0.3%, and they are mixed uniformly to form a foaming agent aqueous solution. Afterwards, it is mixed with steam nitrogen at a volume ratio of 0.5:1 to form the required enhanced foam flooding composition, and the ratio of nitrogen to steam is 1:1.

[0039] Take the above composition under the condition of 200 ℃, in the sand filling pipe with a length of 100 cm, a diameter of 3.8 cm, and a permeability of 1000 mD to carry out the foam plugging ability test, and record the resistance formed after the injection of foam balance and the formation of water injection. The ratio of resistance is the resistance factor, and the results are shown in Table 1.

Embodiment 2

[0041] Dissolve the long-chain polyether nitrogen-containing compound and the long-chain diaryl sulfonate in the water with a salinity of 50,000 mg / L according to the molar ratio of 1:10, and the total mass fraction of the foaming agent is 0.1%, and mix well to form a foaming agent aqueous solution. Afterwards, it is mixed with steam nitrogen according to the volume ratio of 3:1 to realize gas-liquid mixing, that is, to form the required enhanced foam flooding composition, and the ratio of nitrogen to steam is 0.3:1.

[0042] Take the above composition under the condition of 250°C, in a sand filling pipe with a length of 100 cm, a diameter of 3.8 cm, and a permeability of 1000 mD to conduct a foam plugging capacity test, and record the resistance formed after the injection of foam balance and the formation of water injection. The ratio of resistance is the resistance factor, and the results are shown in Table 1.

Embodiment 3

[0044] Dissolve the long-chain polyether nitrogen-containing compound and the long-chain diaryl sulfonate in a molar ratio of 1:0.2 in water with a salinity of 200,000 mg / L, the total mass fraction of the foaming agent is 0.3%, and mix well to form a foaming agent aqueous solution. Afterwards, it is mixed with steam nitrogen at a volume ratio of 4:1 to form the required enhanced foam flooding composition, and the ratio of nitrogen to steam is 2:1.

[0045] Take the above composition under the condition of 200 ℃, in the sand filling pipe with a length of 100 cm, a diameter of 3.8 cm, and a permeability of 1000 mD to carry out the foam plugging ability test, and record the resistance formed after the injection of foam balance and the formation of water injection. The ratio of resistance is the resistance factor, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com