High-tensile-strength energy-saving waterproof paint and preparation method thereof

A technology for waterproof coatings and raw materials, applied in fire-resistant coatings, reflective/signal coatings, coatings, etc., can solve problems such as cracks and easy cracking of building exterior coatings, and achieve the goal of reducing refrigeration costs, reducing material costs, and improving hemispheric emissivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

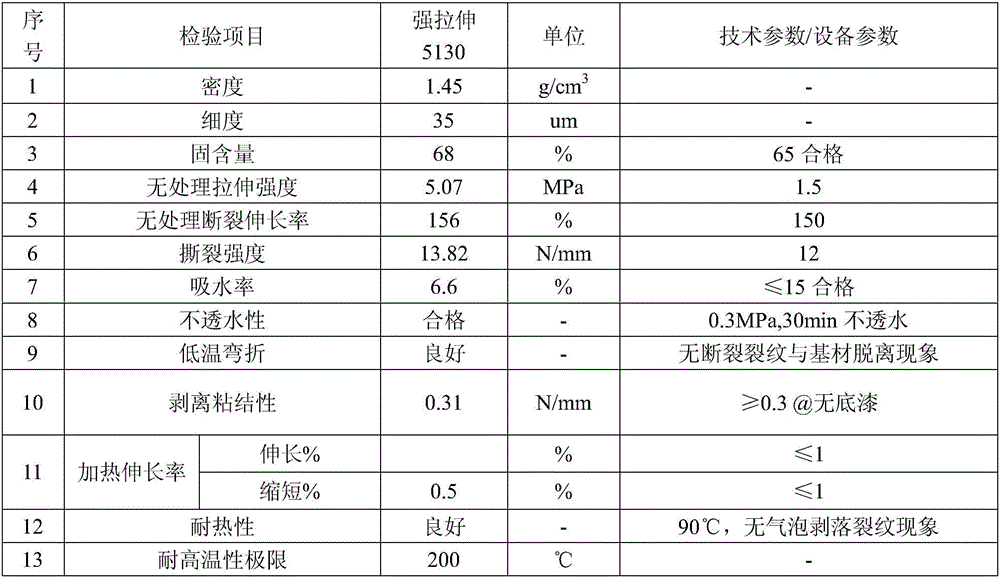

Examples

specific Embodiment approach 1

[0019] A strong tensile energy-saving waterproof coating, the weight parts of each component in the strong tensile energy-saving waterproof coating is: the weight parts of each component in the strong tensile energy-saving waterproof coating raw material is: solvent removal 15 parts of ionized water, 0.7 parts of dispersant, 0.3 parts of defoamer A, 17 parts of filler, 20 parts of nanometer powder, 1 part of ceramic fiber powder, 25 parts of acrylic emulsion, 0.3 parts of defoamer B, ten alcohol esters 0.2 parts of 2, 0.2 parts of anti-mold additives, 0.2 parts of DMAE, 0.1 parts of thickener premix, and 1 part of liquid thickener.

[0020] The dispersant described in this embodiment is formed by uniformly mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; the filler is made of 800 mesh ground calcium carbonate and 150 μm hollow glass The balls are uniformly mixed according to the mass ratio of 4:1; the nano-powder is rutile na...

specific Embodiment approach 2

[0023] A strong tensile energy-saving waterproof coating, the weight parts of each component in the strong tensile energy-saving waterproof coating is: the weight parts of each component in the strong tensile energy-saving waterproof coating raw material is: solvent removal 18 parts of ionized water, 1 part of dispersant, 0.8 parts of defoamer A, 22 parts of filler, 25 parts of nano powder, 3 parts of ceramic fiber powder, 30 parts of acrylic emulsion, 0.8 parts of defoamer B, ten parts of alcohol ester 0.4 parts of two, 0.4 parts of anti-mold additives, 0.4 parts of DMAE, 0.3 parts of thickener premix, and 1.5 parts of liquid thickener.

[0024] The dispersant described in this embodiment is formed by uniformly mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; the filler is made of 800 mesh ground calcium carbonate and 200 μm hollow glass The balls are uniformly mixed according to the mass ratio of 4:1; the nano-powder is rut...

specific Embodiment approach 3

[0027] A strong tensile energy-saving waterproof coating, the weight parts of each component in the strong tensile energy-saving waterproof coating is: the weight parts of each component in the strong tensile energy-saving waterproof coating raw material is: solvent removal 16 parts of ionized water, 0.8 parts of dispersant, 0.5 parts of defoamer A, 20 parts of filler, 23 parts of nano powder, 1.5 parts of ceramic fiber powder, 28 parts of acrylic emulsion, 0.5 parts of defoamer B, ten alcohol esters 0.4 parts, 0.3 parts of anti-mold additives, 0.2 parts of DMAE, 0.3 parts of thickener premix, and 1.5 parts of liquid thickener.

[0028] The dispersant described in this embodiment is formed by uniformly mixing Rohm and Haas OrotanTM 1850E and potassium tripolyphosphate according to a mass ratio of 5:1; the filler is made of 800 mesh ground calcium carbonate and 200 μm hollow glass The balls are uniformly mixed according to the mass ratio of 4:1; the nano-powder is rutile nano-T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com