High strength dry-mixed masonry mortar and preparation method thereof

A masonry mortar and high-strength technology, which is applied in the field of building materials, can solve the problems of low water retention and cohesion, low crack resistance, easy shelling and cracking of mortar, and achieve stable performance, good compactness, and mortar joints. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

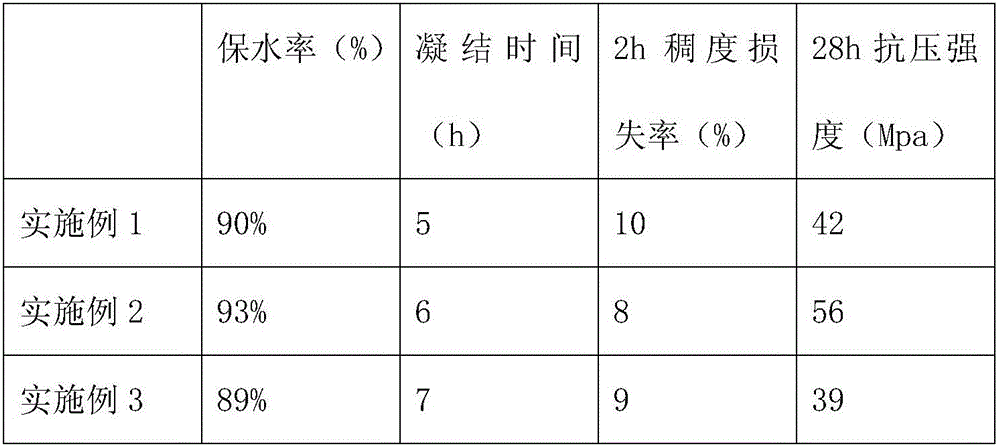

Examples

Embodiment 1

[0018] A high-strength dry-mixed masonry mortar is prepared from the following raw materials in parts by weight: 100 parts of Portland cement, 20 parts of modified dickite powder, 20 parts of blast furnace slag, 10 parts of iron ore tailings, and 3 parts of polyethersulfone parts, 3 parts of limestone, 5 parts of river sand, 2 parts of latex powder, 2 parts of hydroxypropyl methylcellulose, 1 part of water reducing agent, 1 part of sodium rosin, and 2 parts of bonding aid.

[0019] The modified dickite powder is prepared by the following method: calcining dickite at 450° C. for 3 hours, after cooling, soaking in a 10% hydrogen peroxide solution for 3 hours, washing with deionized water until neutral, drying, and then drying the dickite. Add 1% of sodium laurate alkyd, 2% of sodium hexametaphosphate, 2% of cross-linking agent TAC equivalent to its weight, stir at a high speed of 3500 rpm, and after 30 minutes, dry and grind it into nano-powder, namely have to.

[0020] Said bo...

Embodiment 2

[0026] A high-strength dry-mixed masonry mortar is prepared from the following raw materials in parts by weight: 120 parts of Portland cement, 25 parts of modified dickite powder, 15 parts of blast furnace slag, 15 parts of iron ore tailings, and 5 parts of polyethersulfone parts, 5 parts of limestone, 6 parts of river sand, 6 parts of latex powder, 3 parts of hydroxypropyl methylcellulose, 13 parts of water reducing agent, 2 parts of sodium rosin, and 3 parts of bonding aid; the water reducing agent It is a polycarboxylate water reducer.

[0027] The modified dickite powder is prepared by the following method: calcining dickite at 450° C. for 3 hours, after cooling, soaking in a 10% hydrogen peroxide solution for 3 hours, washing with deionized water until neutral, drying, and then drying the dickite. Add 1% of sodium laurate alkyd, 2% of sodium hexametaphosphate, 2% of cross-linking agent TAC equivalent to its weight, stir at a high speed of 3500 rpm, and after 30 minutes, d...

Embodiment 3

[0034] A high-strength dry-mixed masonry mortar is prepared from the following raw materials in parts by weight: 150 parts of Portland cement, 30 parts of modified dickite powder, 10 parts of blast furnace slag, 20 parts of iron ore tailings, 6 parts of polyethersulfone parts, 7 parts of limestone, 10 parts of river sand, 8 parts of latex powder, 5 parts of hydroxypropyl methylcellulose, 5 parts of water reducing agent, 3 parts of sodium rosin, and 5 parts of bonding aid.

[0035] The modified dickite powder is prepared by the following method: calcining dickite at 450 DEG C for 3 hours, after cooling, soaking in 10% hydrogen peroxide solution for 3 hours, washing with deionized water until neutral, drying, and then drying Add 1% of sodium laurate alkyd, 2% of sodium hexametaphosphate, 2% of crosslinking agent TAC equivalent to its weight, stir at a high speed of 3500 rpm, and after 30 minutes, dry and grind it into nano-powder, that is, have to.

[0036] Said bonding aid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com