Transformed buried oil storage tank and transforming method thereof

An oil storage tank and tank body technology is applied in the field of reconstruction of buried oil storage tanks, which can solve the problems of oil leakage, polluting the environment, lack of safety distance, corrosion, etc., and achieves a simple and easy reconstruction method, prolongs service life, and is powerful. The effect of corrosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

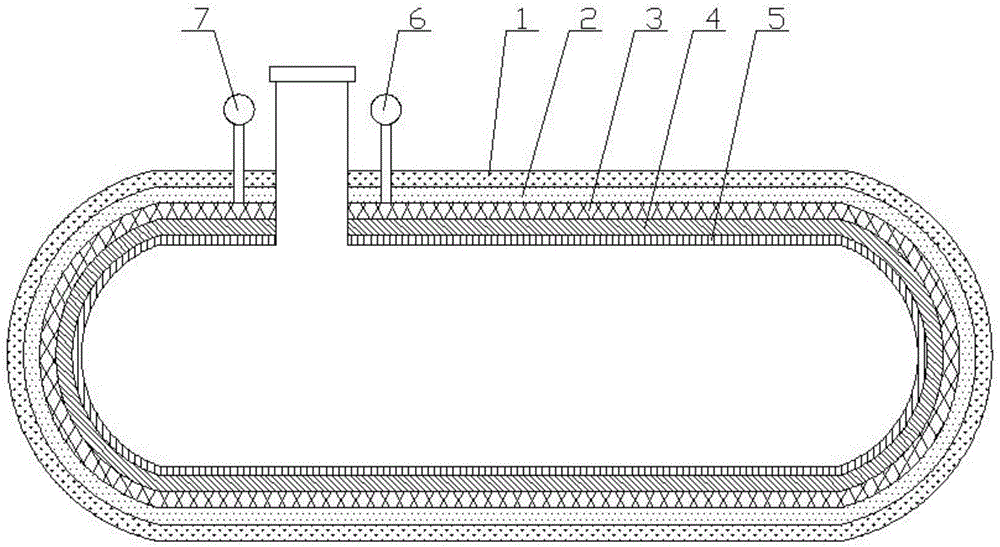

[0024] See figure 1 , a modified buried oil storage tank, has a steel tank body 1, the inner wall of the tank body 1 is provided with a bottom layer 2 formed by laminating fiber cloth and spraying resin and solidified at the same time, and an intermediate layer 3 is arranged on the inner wall of the bottom layer 2 , the middle layer 3 is a three-dimensional spaced one-piece fabric woven with glass fiber as a whole, which is a hollow structure formed by resin compounding. The inner wall of the middle layer 3 is provided with a surface layer 4 which is formed by laminating fiber cloth and spraying resin at the same time. The surface layer 4 A surface protection layer 5 made of electrostatic resin is provided on the inner wall of the body. Wherein, the middle layer 3 is connected with a leak-proof detection system, and the leak-proof detection system includes two conduits drawn from the middle layer 3, an inflation valve 6 installed on one of the conduits and used to fill the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com