Material design 3D printing process based on rock and soil models

A 3D printing and 3D printer technology, applied in the field of 3D printing technology and technology, can solve problems such as controllability, inability to achieve macro and micro structures, and inability to achieve a high degree of simulation effect, so as to improve accuracy, increase the degree of reduction, The effect of improved simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation of the present invention will be further described below in conjunction with examples.

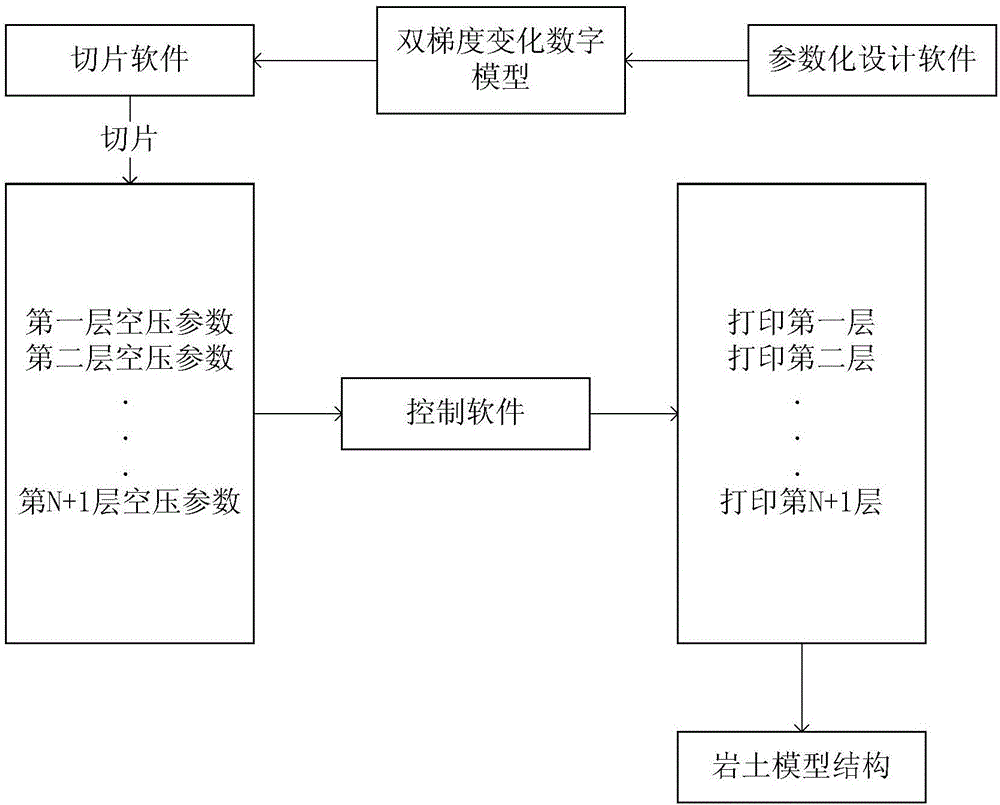

[0020] Please refer to figure 1 and figure 2 , an embodiment of the present invention provides a material design 3D printing process based on a geotechnical model, comprising the following steps:

[0021] (1) Fill the raw material powder and additive slurry of the geotechnical model into the feeding system of the 3D printer. The feeding system includes several injection pipes and one injection pipe. In the pipeline, the additive slurry is filled in the injection pipeline, the number of injection pipelines is consistent with the type of raw materials of the geotechnical model, and the additive slurry is heated to 80°C in the injection pipeline;

[0022] (2) Use parametric design software to design the double-gradient change digital model of the material and structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com