Adjustable double-knife head cutter device and adjustment method for making phenolic air duct

A technology of double cutter heads and cutters, which is applied in metal processing and other directions, can solve the problems of inability to meet the production of irregular phenolic air ducts and the inability to adjust cutter heads, and achieves the effect of overcoming technical defects and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

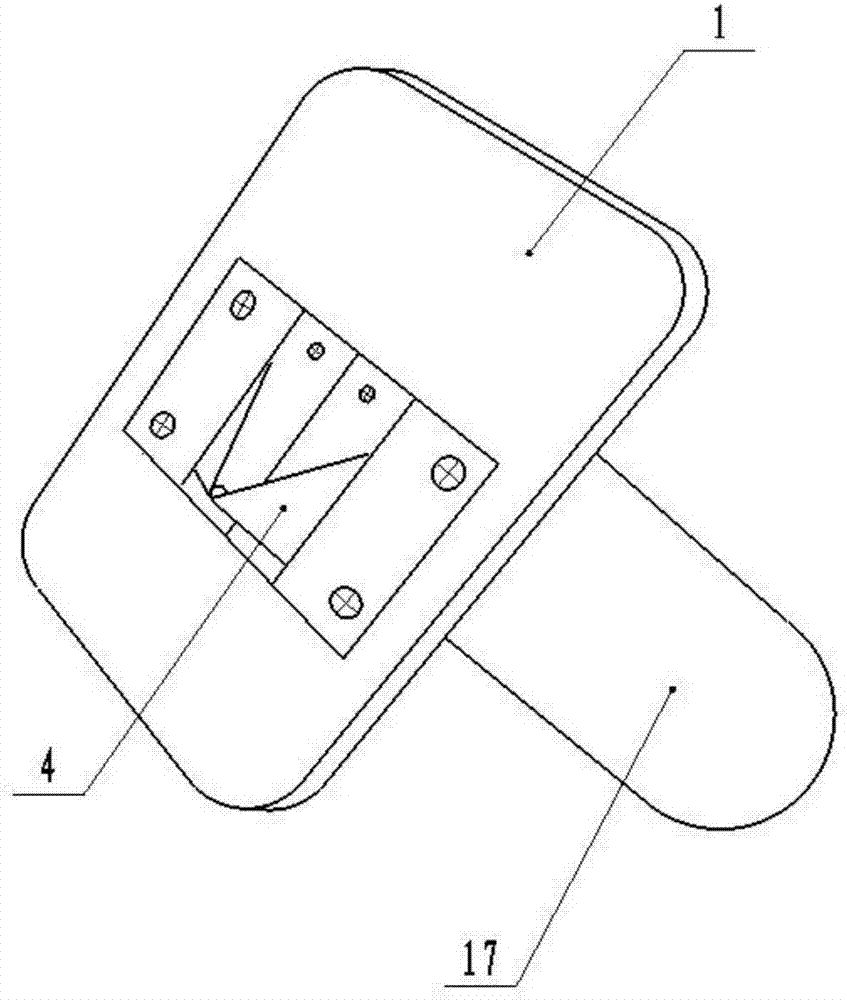

[0036] Such as Figure 3-5 As shown, the present invention is an adjustable double-cutter head cutter device for making phenolic air ducts, including a cutter installation block 1, a cutter adjustment block 2, a cutter adjustment frame 3 and a cutter head 4, a cutter installation block 1, and a cutter adjustment block 2 and tool adjustment frame 3 are made of light aluminum alloy to reduce the type of tool device, easy to use, and easy to process. The tool mounting block 1 is provided with a tool rest mounting groove 5, and the knife rest mounting groove 5 is a concave structure. The cutter adjusting block 2 can be moved in the knife rest mounting groove 5 by adjusting the adjusting block 9 to adjust the cutting distance between the two blades. The bottom of the knife rest mounting groove 5 is provided with a cutter adjusting groove 6; Adjusting frame mounting groove 7, adjusting frame mounting groove 7 two ends are provided with adjusting hole 8, cutter adjusting block 2 bott...

Embodiment 2

[0042] Such as Figure 3-5 As shown, a kind of adjustable double cutter head cutter adjustment method for making phenolic air duct of the present invention, on the basis of embodiment 1, comprises steps:

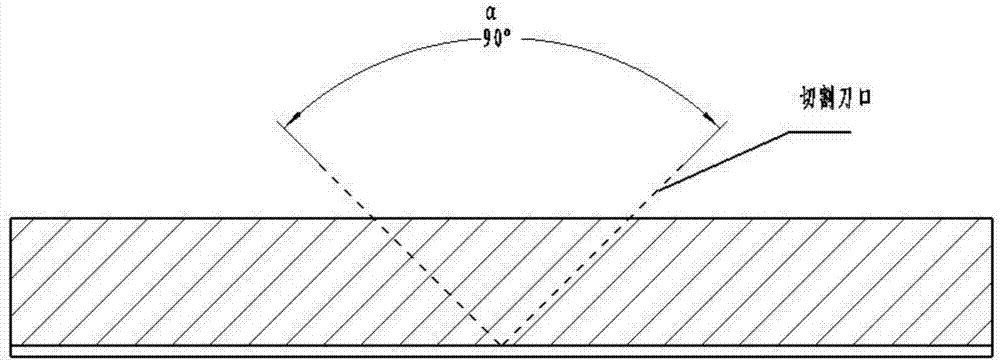

[0043] Step 1) Calculate the protruding length of the cutter head according to the cut angle α of the phenolic air duct made and the thickness d of the cut phenolic formaldehyde;

[0044] Cot1 / 2α=d / S (1)

[0045] S is the length of the tool head protruding from the tool mounting block

[0046] Deduced by formula (1), S=d / (Cot1 / 2α) (2);

[0047] Step 2) adjust the cutter head extension length S according to the cutter head extension length S obtained from the formula (2);

[0048] Step 3) Calculate the distance between the roots of the two cutter heads according to the cut angle α of the phenolic air duct made and the thickness d of the cut phenolic formaldehyde;

[0049] tan1 / 2α=K / 2S (3)

[0050] K is the distance between the roots of the two cutter heads

[0051] Dedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com