Annular fine water mist fire extinguishing cover system

A technology of water mist and fire extinguishing hood, which is applied in fire rescue and other directions, can solve the problems of pollution, slow fire extinguishing speed and large fire extinguishing dose, and achieve the effect of overcoming low fire extinguishing efficiency, fast fire extinguishing speed and high fire extinguishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

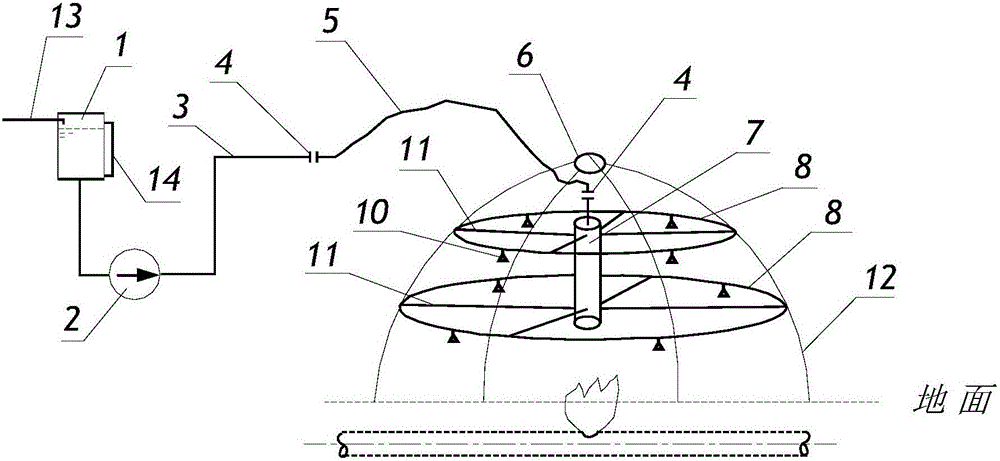

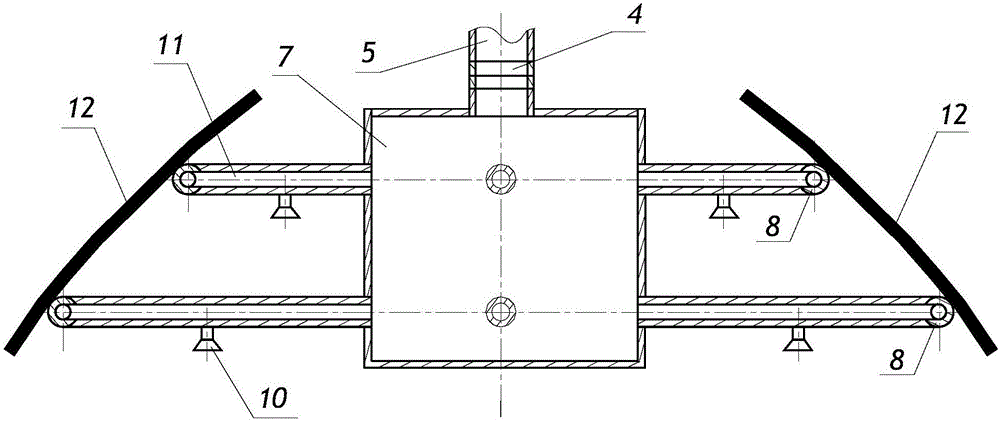

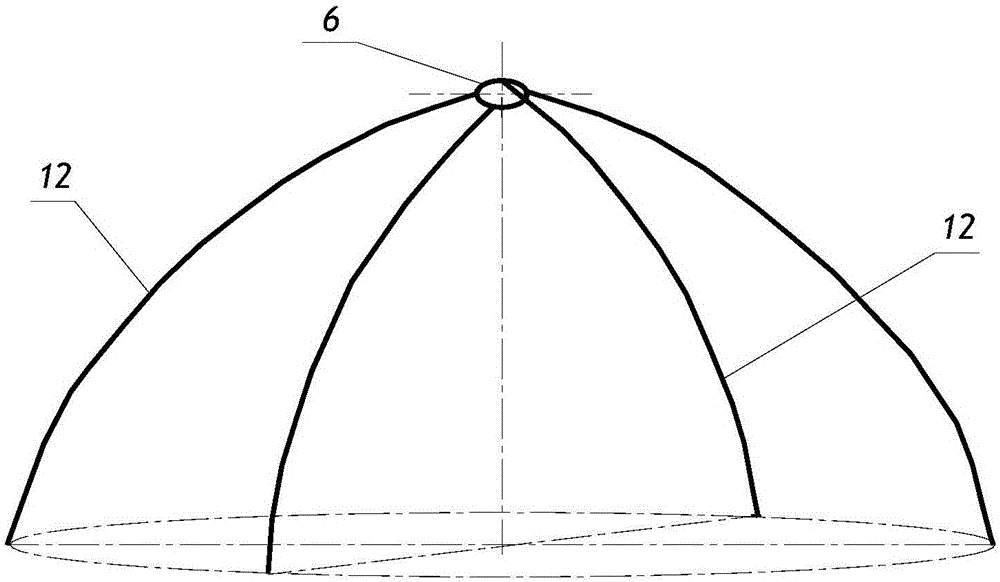

[0025] see Figure 1 to Figure 4 , the ring-shaped water mist fire extinguishing hood system of an embodiment of the present invention includes a water mist injection mechanism, and the water mist injection mechanism includes a high-pressure water distributor 7 and more than two annular water pipes 8, each annular water pipe 8 is connected to the The high-pressure water distributors 7 are connected to each other through one or more high-pressure water distribution pipes 11, and each annular water pipe 8 is respectively provided with two or more fine water mist nozzles 10.

[0026] When the above-mentioned system is in use, the high-pressure water distributor 7 supplies high-pressure fire extin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com