Perfume and method for preparing perfume by using ultrasonic aging accelerating

A perfume and ultrasonic technology, which is applied to the formulation of perfume preparations, cosmetic preparations, pharmaceutical formulations, etc., can solve the problems of backlog, equipment occupied funds, long time consumption, etc., and achieves reduction of aging time, improvement of production efficiency, and simple method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

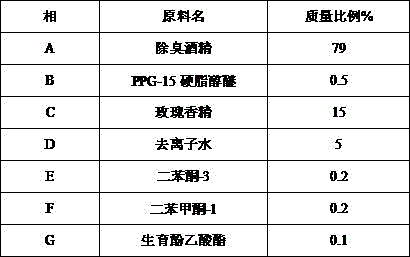

[0030] Rose perfume is prepared by ultrasonic aging method, and the perfume formula is as follows:

[0031]

[0032] Preparation method: Add phase A, phase B, phase C, and phase D into the stainless steel reaction pot in sequence according to the proportion of the formula, cover the pot, and place it in the ultrasonic reaction tank, set the ultrasonic frequency of the ultrasonic instrument to 20KHz, each time The ultrasonic time is 20 minutes, and it is ultrasonicated once every 20 minutes. Set the ultrasonic temperature to 15°C, and perform ultrasonication 6 times. The machine is refrigerated at 0~5°C for 24 hours, filtered, sampled and tested, and discharged after passing the test.

[0033] The fragrance quality and physical and chemical indicators of the perfume made by the ultrasonic process and the perfume made by the traditional process are compared, and the results are as follows:

[0034] Fragrance quality comparison results:

[0035] Fragrance Quality Sc...

Embodiment 2

[0039] Jasmine perfume is prepared by ultrasonic aging method, and the perfume formula is as follows:

[0040] Mutually Raw material name Mass ratio% A deodorant alcohol 85.55 B PEG-40 Hydrogenated Castor Oil 0.2 C Jasmine essence 10 D Deionized water 4 E Isooctyl p-methoxycinnamate 0.1 F Menthyl anthranilate 0.1 G 2,6-di-tert-butyl-p-cresol 0.05

[0041] Preparation method: Add phase A, phase B, phase C, and phase D into the stainless steel reaction pot in sequence according to the proportion of the formula, cover the pot, and place it in the ultrasonic reaction tank, set the ultrasonic frequency of the ultrasonic instrument to 25KHz, each time The ultrasonic time is 25 minutes, and it is ultrasonicated once every 25 minutes. Set the ultrasonic temperature to 15°C, and perform ultrasonication 5 times. The machine is refrigerated at 0~5°C for 24 hours, filtered, sampled and tested, and discharged after passing ...

Embodiment 3

[0048] Jasmine perfume is prepared by ultrasonic aging method, and the perfume formula is as follows:

[0049] Mutually Raw material name Mass ratio% A deodorant alcohol 86 B PEG-40 Hydrogenated Castor Oil 0.5 C lavender essence 12 D Deionized water 1.00 E Isooctyl salicylate 0.2 F 2-Hydroxy-4methoxybenzophenone 0.2 G Lecithin 0.1

[0050] Preparation method: Add phase A, phase B, phase C, and phase D into the stainless steel reaction pot in sequence according to the proportion of the formula, cover the pot, and place it in the ultrasonic reaction tank. Set the ultrasonic frequency of the ultrasonic instrument to 28KHz. The ultrasonic time is 30 minutes, and it is ultrasonicated once every 30 minutes. Set the ultrasonic temperature to 15°C, and perform ultrasonication 4 times. The machine is refrigerated at 0~5°C for 24 hours, filtered, sampled and tested, and discharged after passing the test.

[0051] The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com