Food processing method of flour food maker

A food processing and pasta machine technology, applied in dough extruders, household appliances, applications, etc., can solve the problems affecting the success rate of noodle making and the accuracy of weighing flour, so as to avoid the uncoordinated flour-water ratio and improve The success rate of noodle making and the effect of accurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

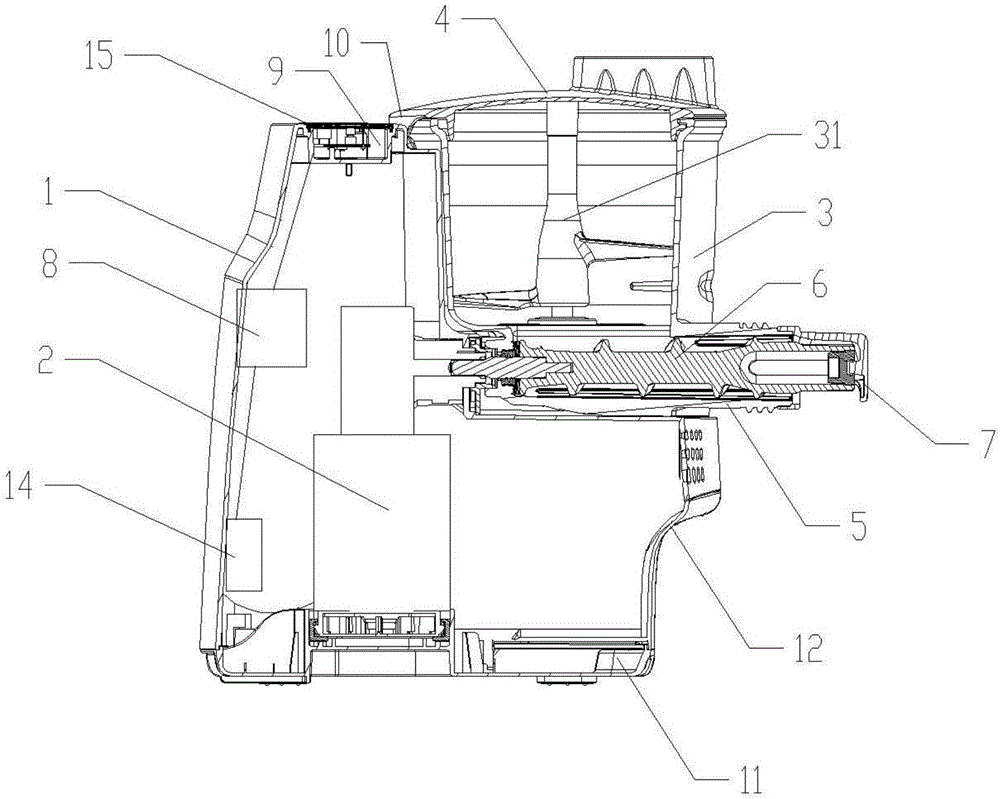

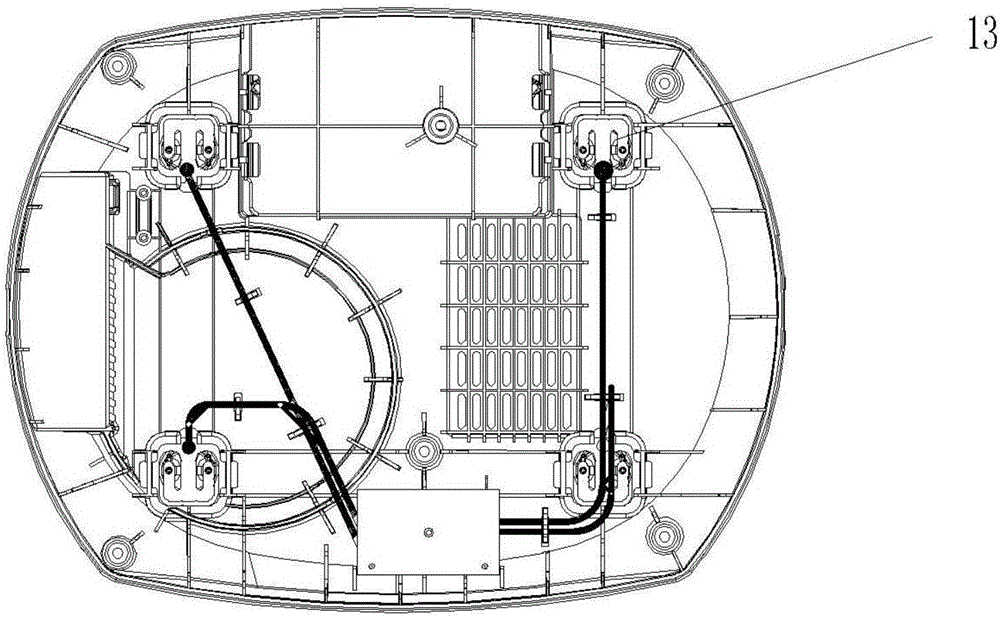

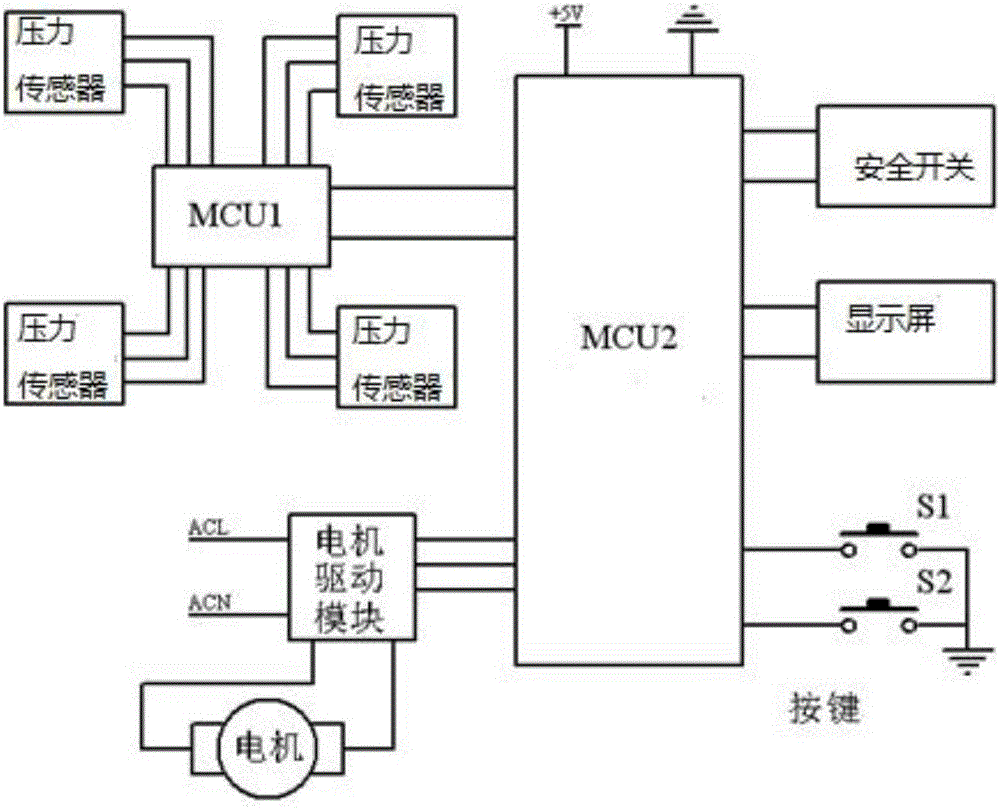

[0034] Such as figure 1 As shown, a noodle machine with accurate weighing, the noodle machine described in this embodiment is a noodle machine for making noodles, and is a vertical noodle machine, including a base 1, a weighing unit for weighing . A signal output unit for outputting weight information, a motor 2 arranged in the base, a stirring assembly arranged on the base, the motor is driven by a motor drive module, and the stirring assembly includes a stirring cup 3, The stirring rod 31 positioned in the stirring cup and the cup cover 4 that is positioned above the stirring cup and is provided independently also include a dough extruding assembly, and the dough extruding assembly includes a dough extruding cylinder 5, a screw rod 6 arranged in the extruding cylinder and a Extrude the die head 7 at the end of the cylinder. A main control board 8 is arranged in the said machine base, said weighing unit is electrically connected with the main control board, a signal output u...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that the noodle making stage also includes an automatic water weighing step: the weighing unit weighs the water addition information and feeds it back to the main control board, and the main control board outputs the water difference through the signal output unit. In this embodiment, the difference in water quantity is displayed through the display screen. The ready-to-use weighing unit is not only used to weigh flour, but also can weigh the amount of water calculated by the surface-to-water ratio. The advantage of this setting is that by setting the automatic weighing step, the user can display the water amount in real time during the process of adding water. Through The signal output unit can intuitively judge the difference between the amount of water to be added and the actual amount of water calculated by the surface-to-water ratio, so as to output how much water the user still needs to add, which is conven...

Embodiment 3

[0075] The difference between this embodiment and Embodiment 1 is that the pasta machine in this embodiment is a bread machine, the pasta machine further includes a heating element, the stirring cup is a metal stirring cup, and the heating element heats the stirring cup. The rest of the other embodiments, such as the weighing structure, are all applicable to this embodiment. The structure of the bread machine is the general structure of the existing household bread machine, and this application will not repeat them in detail.

[0076] Of course, the pasta machine can also be a household steamed bread machine, and the structure of the household steamed bread machine is the general structure of the existing household steamed bread machine, which will not be described in detail in this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com