Sleeving and film taking-up method of greenhouse film

A greenhouse film and sleeve joint technology, which is applied in the fields of botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of difficult film collection, time-consuming and laborious, economic loss, etc., to ensure the insulation effect and easy to use , Guarantee the effect of functional traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

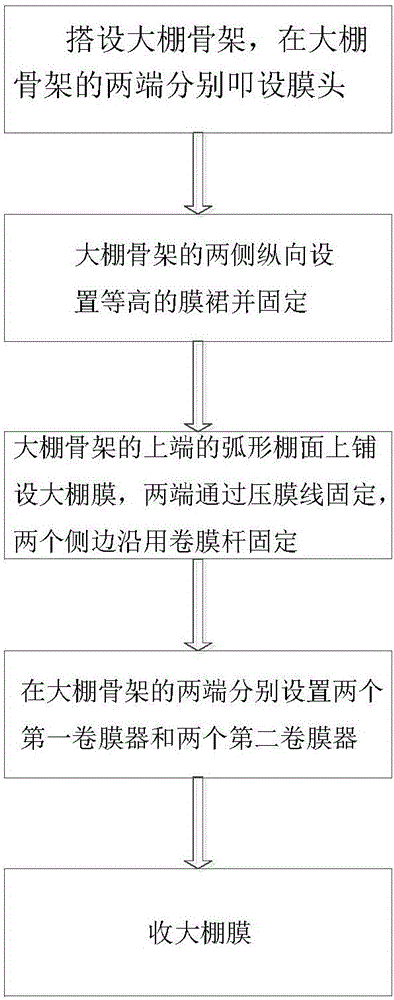

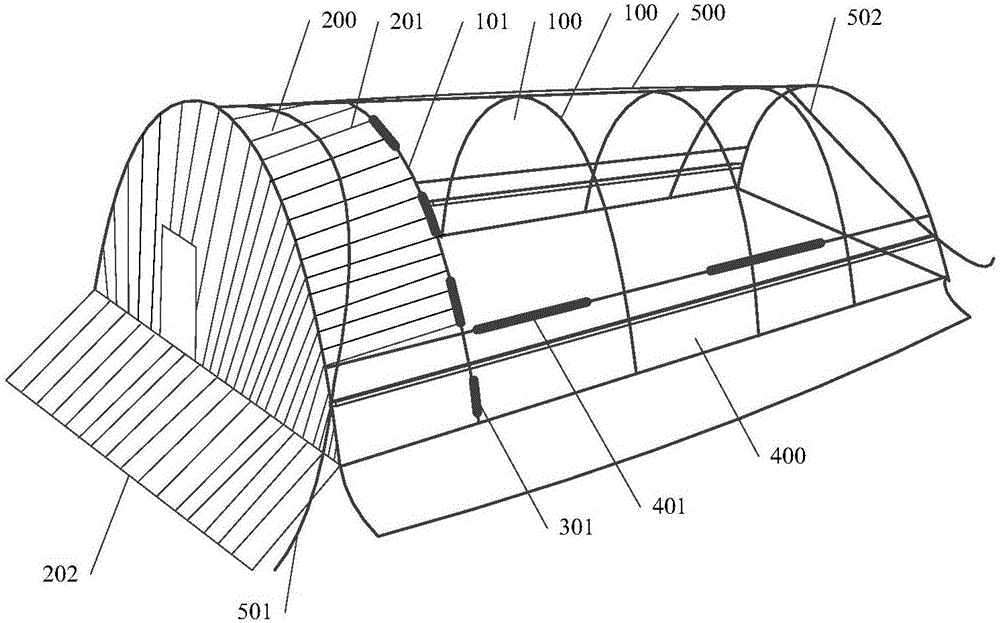

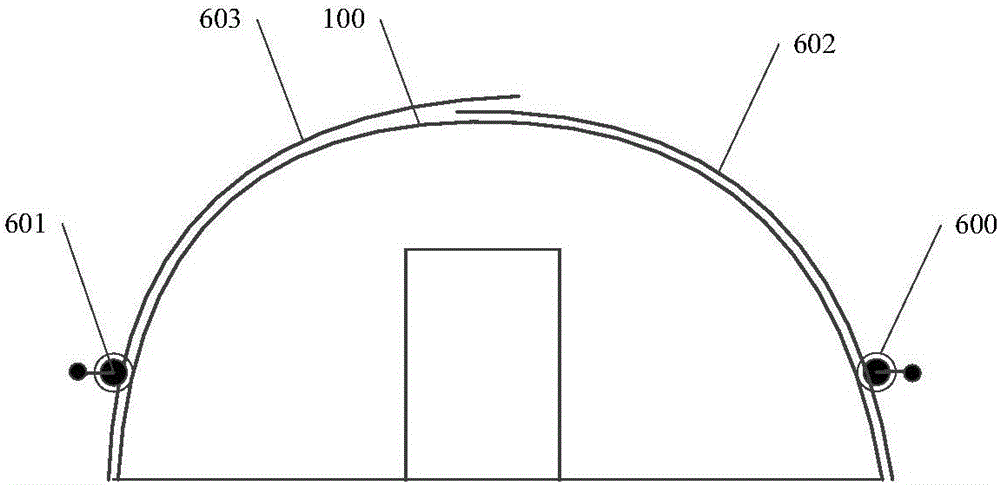

[0033] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a method for sleeve joints and film harvesting of greenhouse films, comprising the following steps:

[0034] Step 1. After erecting and fixing the greenhouse framework 100, cut two pieces of shed film whose length is 120-140 cm longer than the highest height of the greenhouse framework, and use them as membrane heads 200 to respectively cover and fix them on both ends of the greenhouse framework. One end 201 of the head extends to the second beam 101 of the greenhouse framework and is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com