Multi-core optical fiber, optical cable and optical connector

A multi-core optical fiber and fiber core technology, which is applied in the directions of multi-core optical fiber, multi-layer core/cladding optical fiber, glass optical fiber, etc., can solve the problem of easy degradation of signal optical signal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] [Description of Embodiments of the Present Invention]

[0072] First, the contents of the embodiments of the present invention will be individually listed and described.

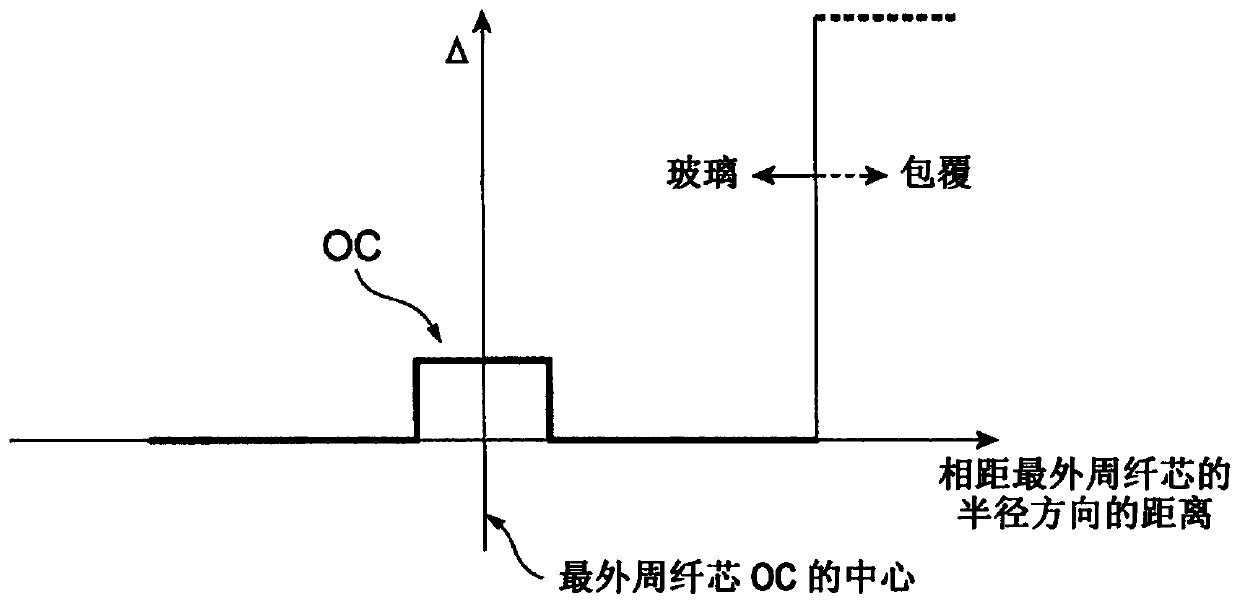

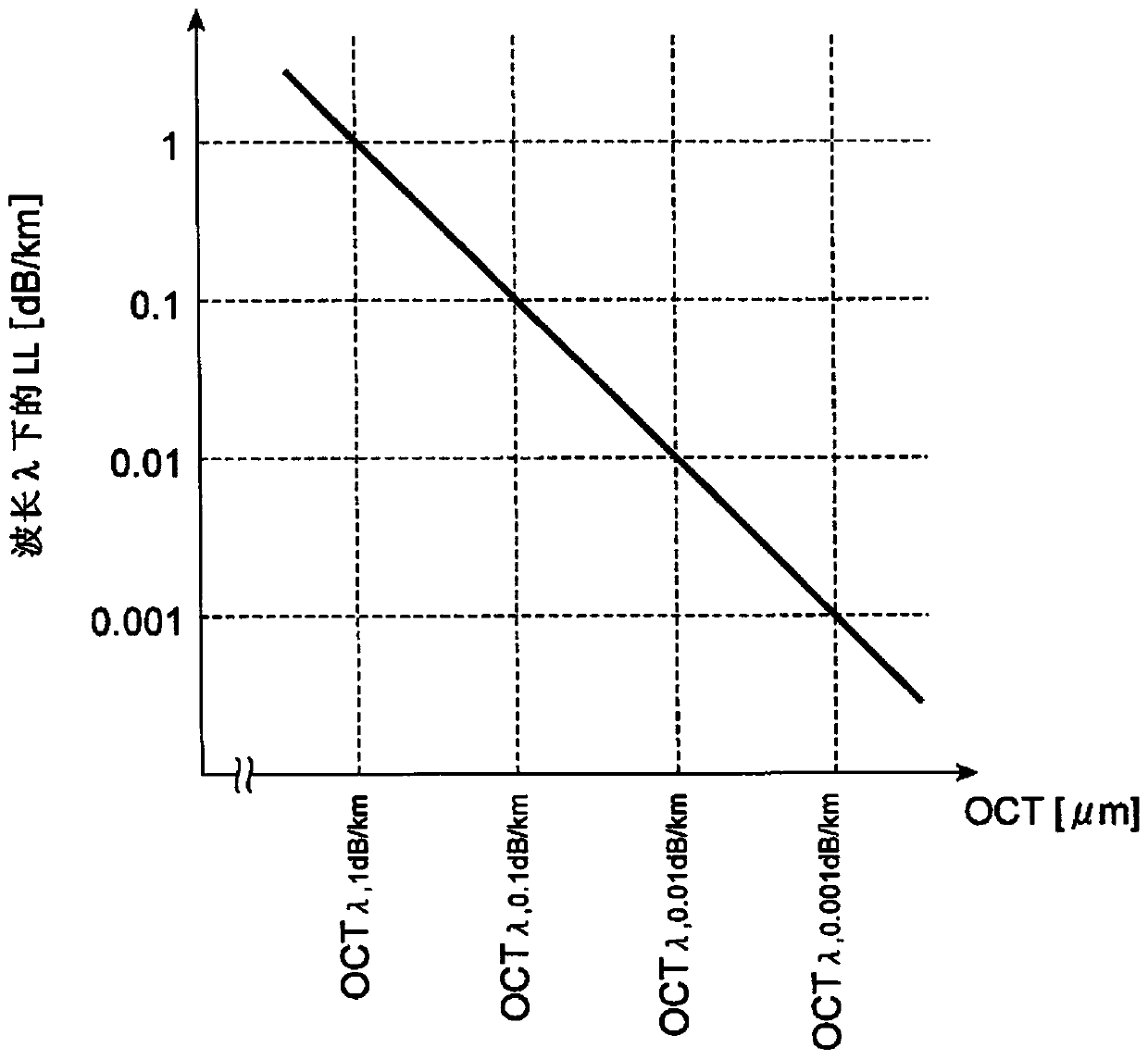

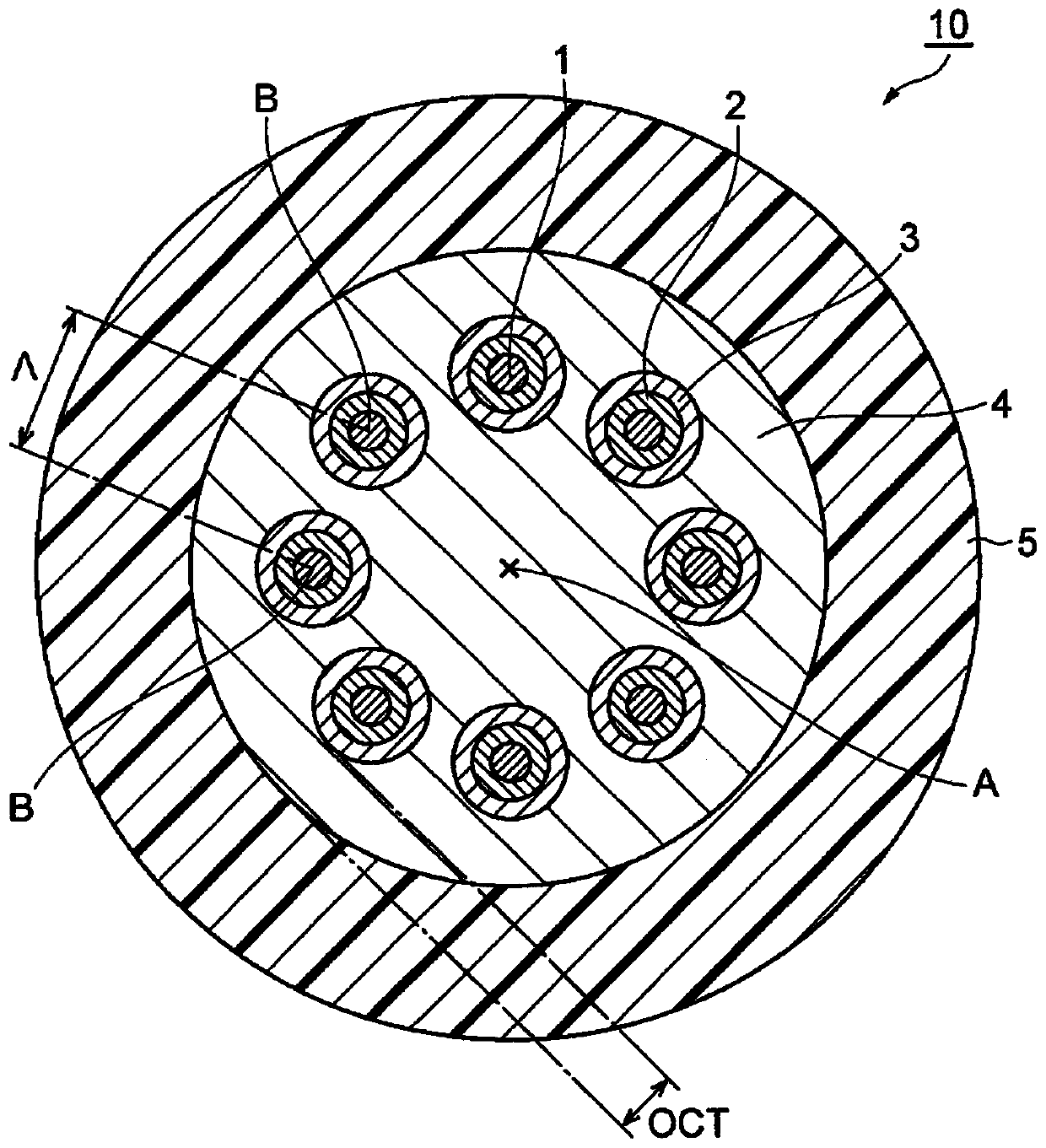

[0073] (1) An aspect of the MCF according to the present embodiment includes: a core group consisting of eight or more cores; an inner cladding group consisting of inner cladding layers each having eight or more cores; Corresponding cores in the cores are individually surrounded; groove groups, which are composed of grooves, which respectively surround corresponding inner claddings in the inner cladding; common cladding, which respectively The grooves are individually surrounded; and the resin cladding surrounds the common cladding. In addition, in this MCF, each core, each inner cladding, each trench, and common cladding are made of silica glass. The diameter of the common cladding is less than or equal to 126 μm. For each core, each inner cladding layer, each trench, common cladding layer, and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com