Brake pad of a disc brake

A technology of disc brakes and brake linings, applied in the components of brakes, brake types, friction linings, etc., can solve problems such as more expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

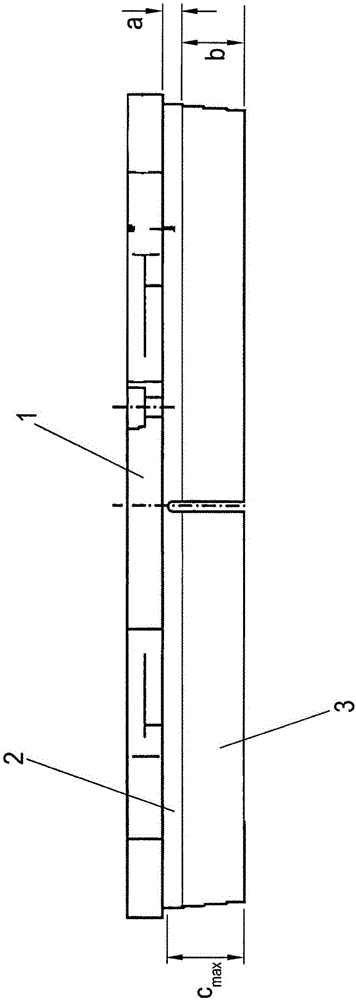

[0021] The drawing shows a brake lining of a disc brake with a lining support plate 1 made of metal or another suitable material and can be made, for example, of cast iron or metal board made.

[0022] An intermediate layer 2 is fastened to the lining support plate 1, usually by adhesive bonding and / or a form-fit connection, which carries the abrasive friction lining 3, which during operation, that is, during production contact the brake discs on the vehicle under clamping pressure when moving. The friction lining 3 is here preferably bonded to the intermediate layer in a materially bonded manner.

[0023] The brake lining shown is, so to speak, a new product, ie the friction lining 3 is unused and is at its maximum thickness b. The thickness of the intermediate layer 2 is denoted by a.

[0024] According to the invention, the thickness of the unused friction lining 3 is less than the specified maximum wear limit c max , where the thickness b of the friction lining 3 plus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com