Rotary pressure filter apparatus with reduced pressure fluctuations

A filter and rotary technology, which is applied in the direction of mobile filter element filter, membrane filter, filtration separation, etc., can solve the problem of pressure fluctuation of rotary pressure filter, and achieve the problem of pressure fluctuation, high capacity and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

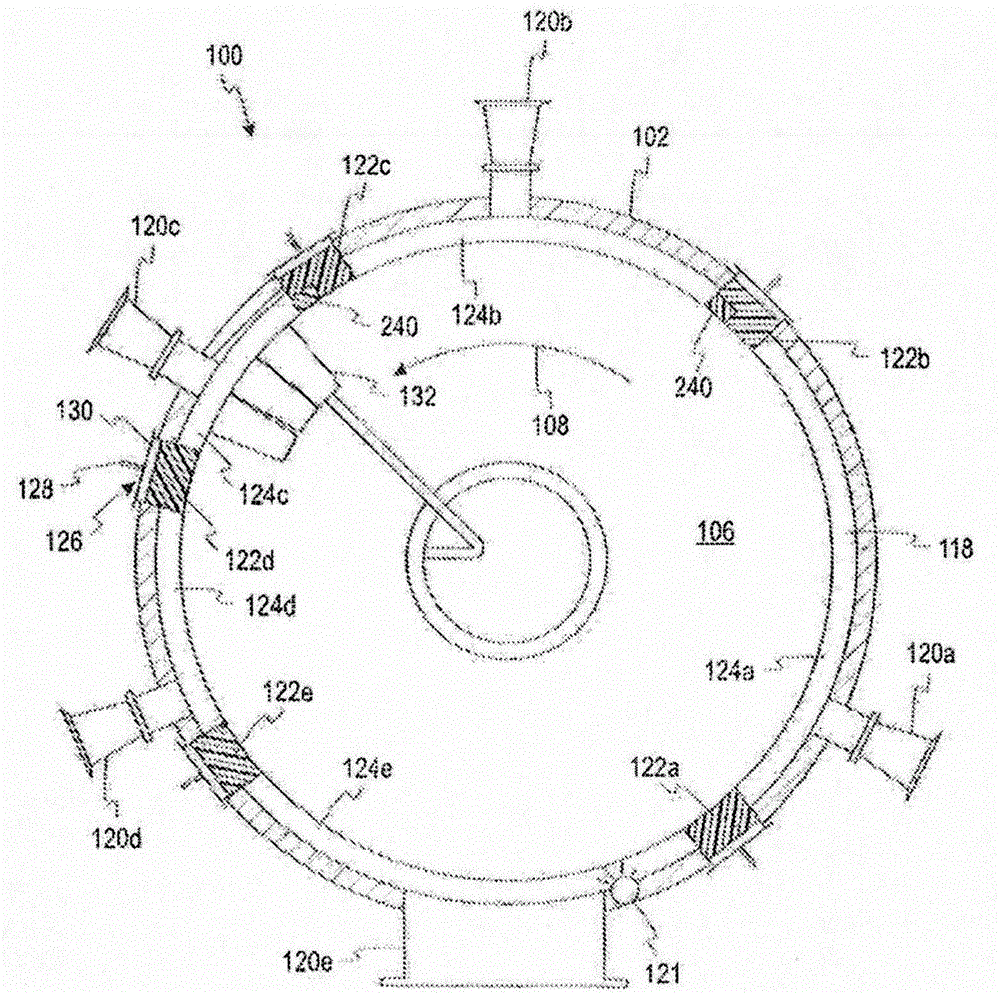

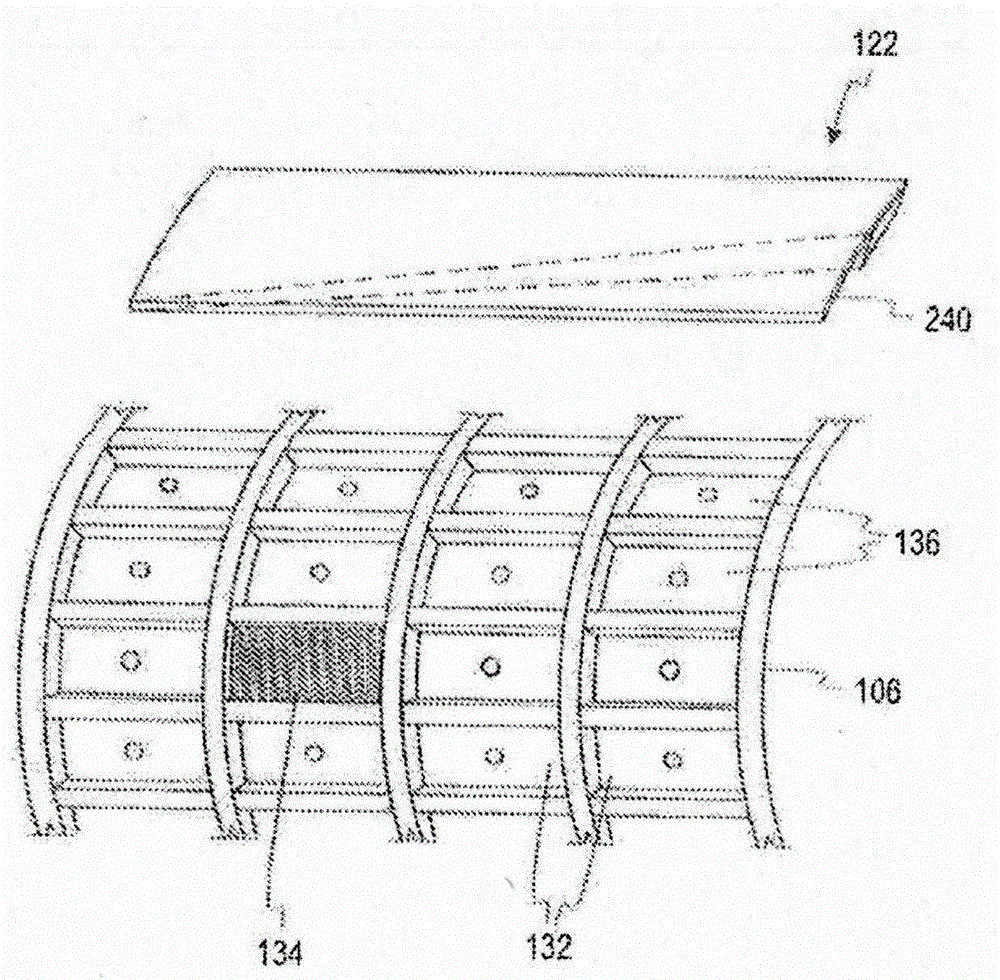

[0021] As a general introduction, the present invention relates to rotary pressure filter apparatus for processing solid-liquid mixtures in a plurality of successive work zones. Rotary pressure filter devices are generally known in the art and are disclosed, for example, in US Patent Nos. 2,741,369, 7,807,060 and US Patent Application 20050051473.

[0022] In some embodiments, the rotary pressure filter apparatus is used to recover solid product or liquid, or both, from a solid / liquid mixture. In some embodiments, the solid product is a pharmaceutical or food ingredient product. In other embodiments, the solid product is a chemical, or especially a petrochemical. In some embodiments, the product is an aromatic hydrocarbon, such as p-xylene. In other embodiments, the product is an aromatic carboxylic acid, such as terephthalic acid.

[0023] now refer to figure 1 , shows a longitudinal section of a rotary pressure filter device, generally indicated at 100 , according to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com