Telescopic type clamp-on ammeter for overhead line measurement

A clamp ammeter, telescopic technology, applied in the direction of measuring current/voltage, only measuring current, measuring electrical variables, etc., can solve the problem that the volume of the clamp-shaped iron core cannot be too large, and the opening of the clamp and the wire cannot be accurately visually inspected. The success rate has a great relationship with the proficiency of engineering personnel, so as to improve the success rate and work efficiency of the operation and realize the effect of visual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further specifically described below through examples.

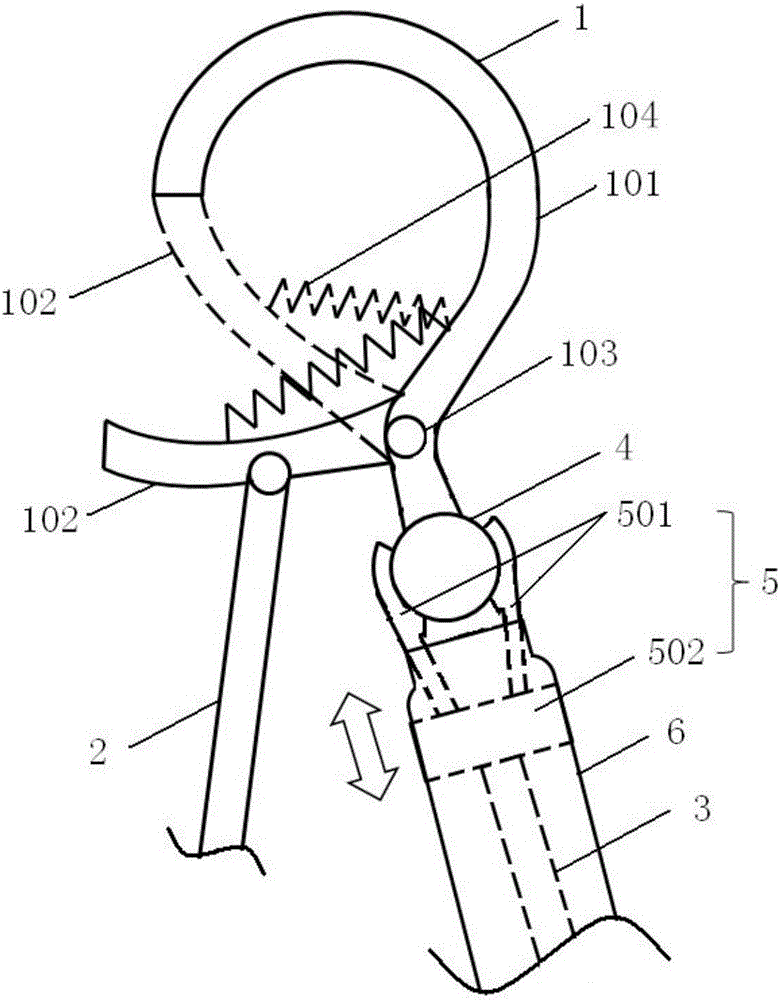

[0025] figure 2 It is a schematic diagram of the overall structure of the telescopic clamp ammeter used for overhead line measurement according to the present invention. The telescopic clamp ammeter includes iron core clamp head 1, clamp head operating rod 2, telescopic rod 3, steering ball head 4, ball head fixing fixture 5, threaded sleeve rod 6, current measuring part (not shown), display ( not shown).

[0026] Wherein, the iron core pliers 1 specifically includes a fixed pliers part 101 , a movable pliers part 102 , a twist joint part 103 , and a spring part 104 . Both the fixed jaw part 101 and the movable jaw part 102 are connected to each other by a twist joint 103, and the movable jaw part 102 can surround the twist joint 103 within an angular range of 0 degrees to 90 degrees Rotate relative to the fixed pliers part 101 to open or close the jaws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com