Heat self-balancing metal hydride hydrogen supercharging device

A technology of hydride hydrogen and supercharging devices, which is applied in the direction of liquid variable displacement machinery, piston pumps, machines/engines, etc., and can solve problems such as sealing, stability influence, complicated operation, and low compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

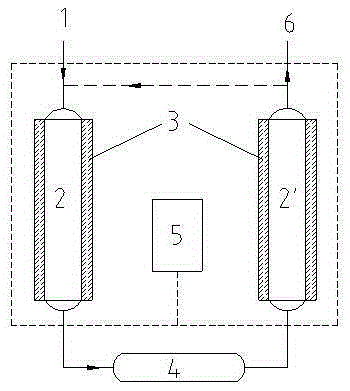

Embodiment 1

[0019] Two-stage compression metal hydride hydrogen pressurization device, including two metal hydride compression units 2 and 2', a heat exchange unit 3, and a control unit 5, and metal hydride compression units 2 and 2' are filled with rare earth hydrogen storage materials , there is a hydrogen return channel between the metal hydride compression units 2 and 2', and the heat exchange unit 3 is an electric heating plate with a maximum temperature of 200°C, wrapped on the outer wall of the metal hydride compression units 2 and 2'; the hydrogen source 1 inputs low-pressure hydrogen To the metal hydride compression unit 2, the hydrogen that has undergone primary compression is first stored in the buffer container 4, and after reaching the specified pressure, it enters the metal hydride compression unit 2', and after the secondary compression, the device can output high-pressure hydrogen 6. When the output pressure is insufficient, the hydrogen gas flows back into the metal hydrid...

Embodiment 2

[0021] Three-stage compression metal hydride hydrogen pressurization device, including three metal hydride compression units 2, 2' and 2'', heat exchange unit 3, control unit 4, metal hydride compression units 2, 2' and 2' 'The interior is filled with titanium-based hydrogen storage materials. The heat exchange unit 3 is an electric heating jacket, which can set a maximum temperature of 500°C and has a heat insulation function. The heat exchange unit 3 is wrapped in metal hydride compression units 2, 2' and 2' 'Outer wall; the hydrogen source 1 inputs low-pressure hydrogen into the metal hydride compression unit 2, and after three stages of compression, the device can output high-pressure hydrogen 5, and the automatic operation of the metal hydride hydrogen pressurization device is realized through the control unit 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com