Intelligent sample bottle lid pressing machine for sampling

A technology of capping machine and bottle cap, which is applied in the direction of flanged bottle caps, etc., can solve the problems of affecting the safety of packaging, low work efficiency, and low degree of intelligence, so as to improve safety and continuity and save working time , the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

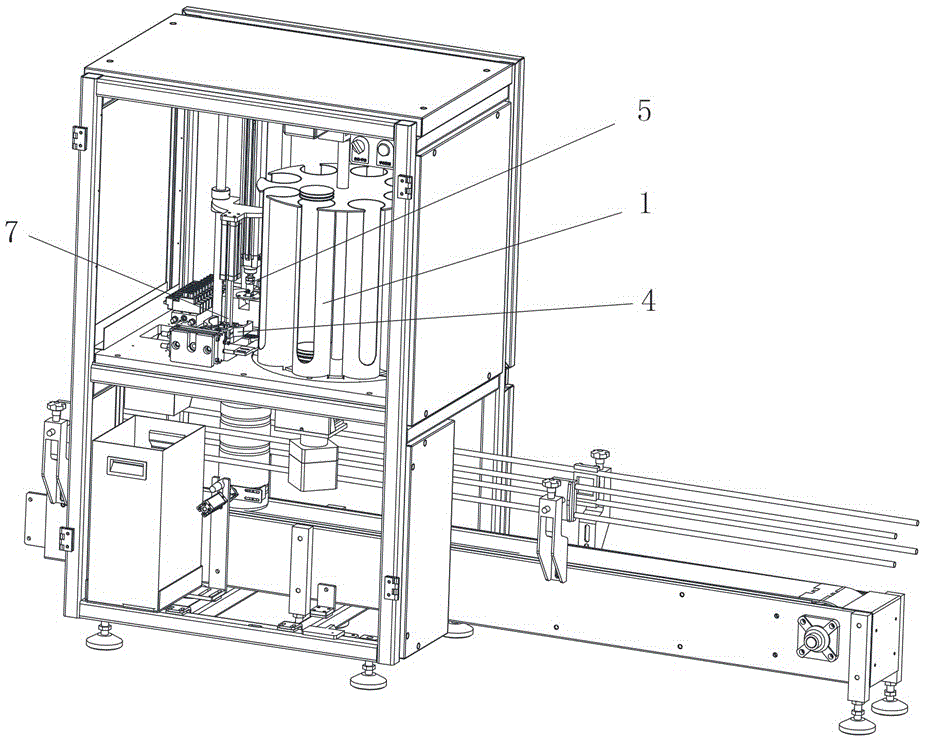

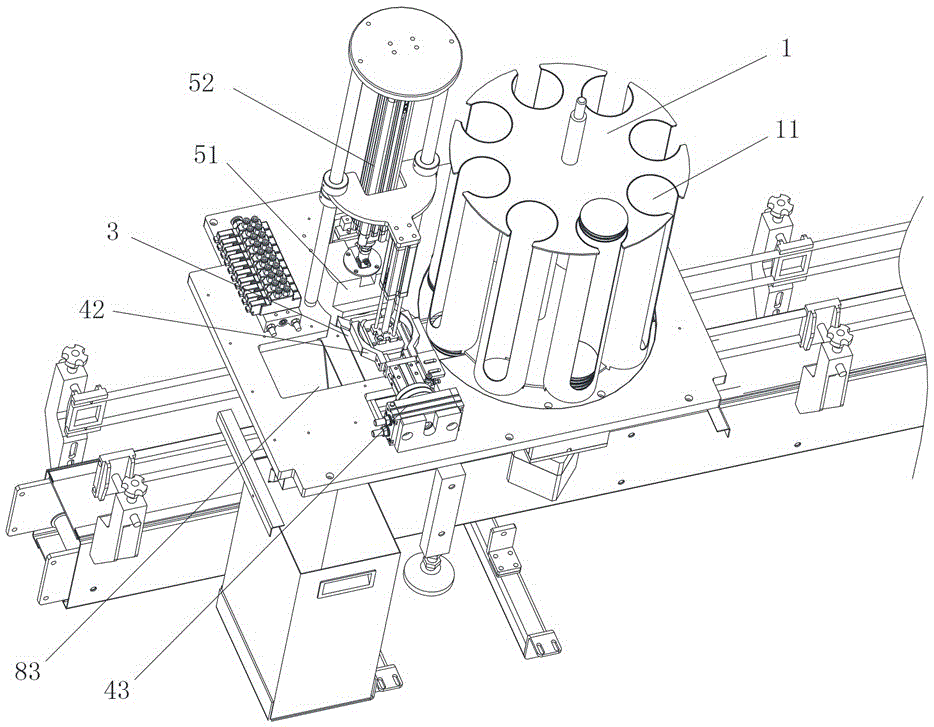

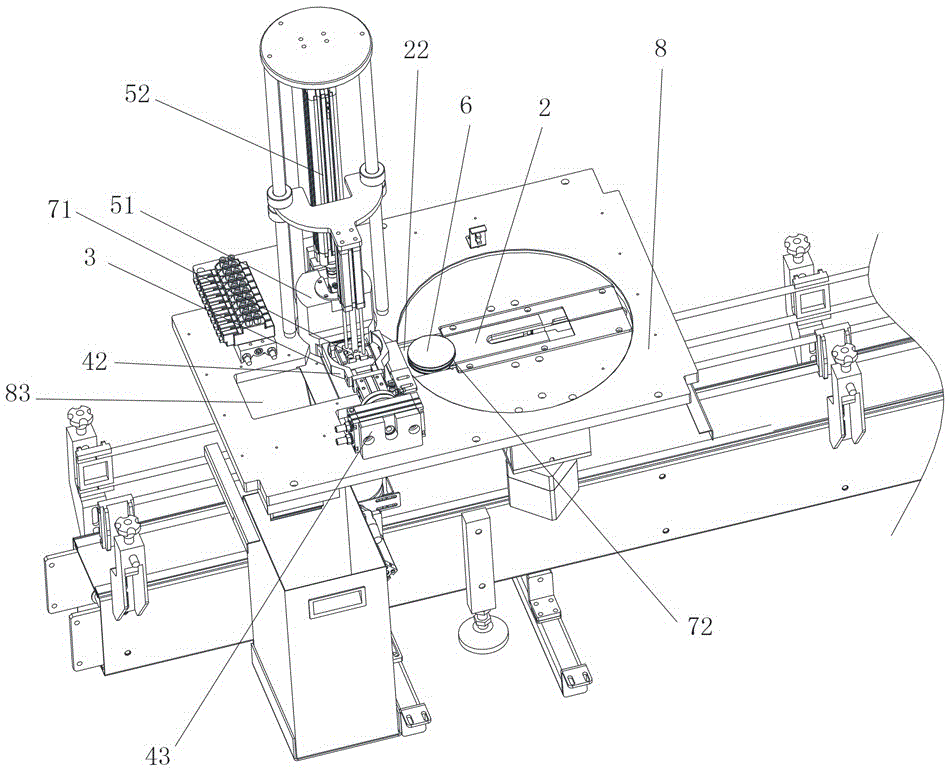

[0052] Such as Figure 1 to Figure 9 As shown, the present invention provides an intelligent sample bottle capping machine for sample collection and processing, including a storage mechanism 1, a push block assembly 2, a translation jacking mechanism 3, a flip correction mechanism 4, a capping mechanism 5 and a detection mechanism 7. The storage mechanism 1 is used to store a plurality of bottle caps 6, and the push block assembly 2 is arranged under the storage mechanism 1 to horizontally push the bottle caps 6 output by the storage mechanism 1 to the translational jacking mechanism 3 one by one, and the translational jacking Mechanism 3 has a translation stroke for translating and transporting the normal bottle caps 6 output by storage mechanism 1 with their caps facing downwards to the bottom of capping mechanism 5 for capping operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com