Machine tools including punching units and laser processing units

A technology of laser processing and stamping devices, which is used in metal processing machinery parts, metal processing, auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

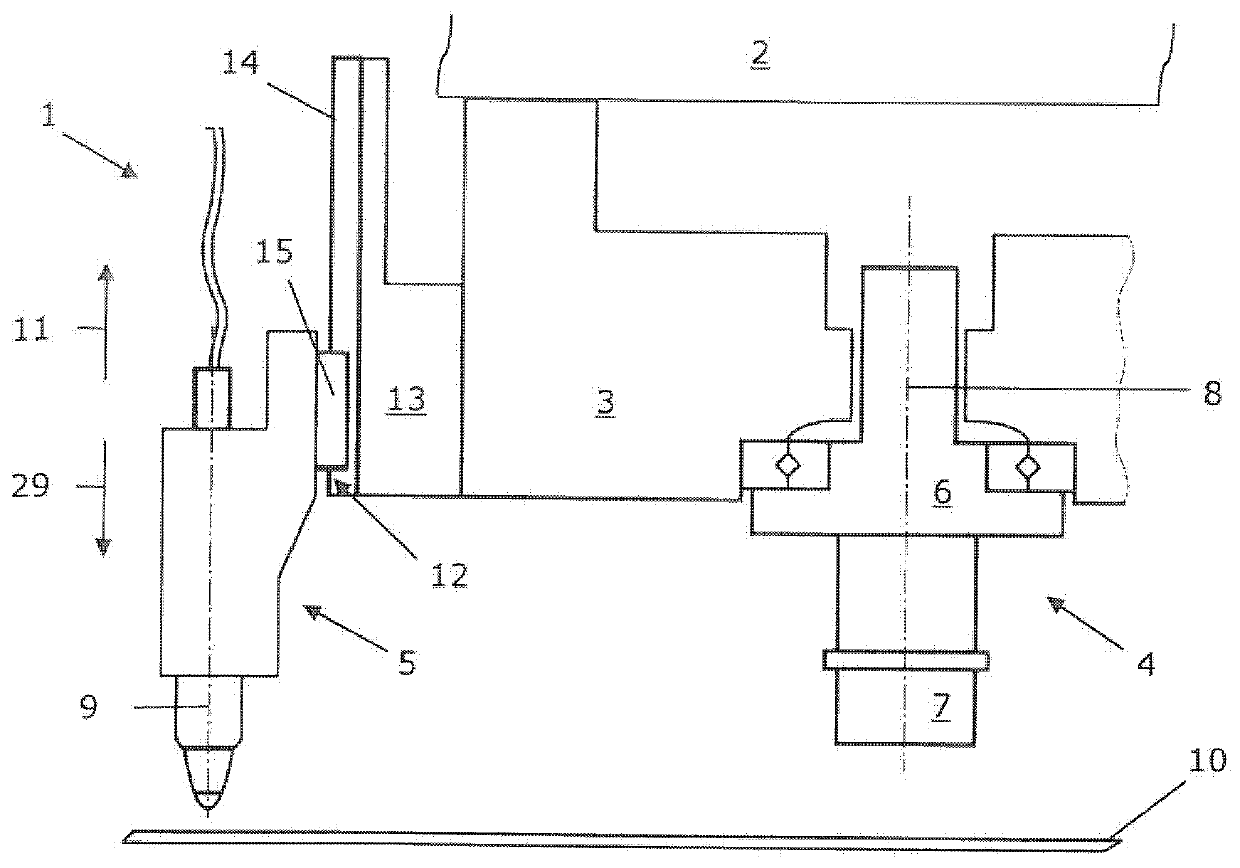

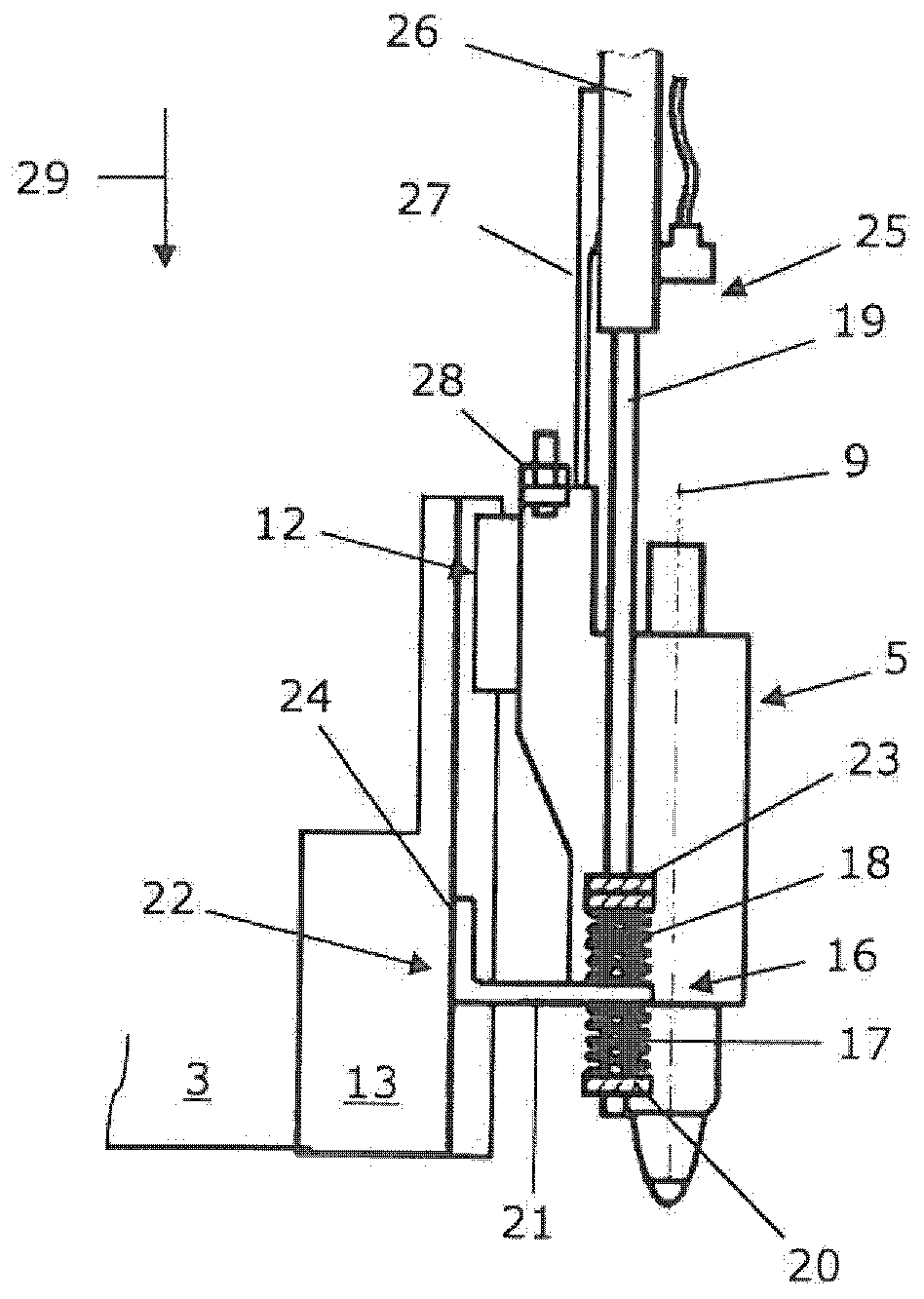

[0028] according to figure 1 , the machine tool 1 designed as a stamping-laser combination machine comprises a frame 2 . Support structure 3 can be perpendicular to on frame 2 figure 1 The view plane moves. The support structure 3 is equipped with a stamping device 4 and a laser processing device in the form of a laser cutting head 5 . Both the stamping device 4 and the laser cutting head 5 are of conventional design.

[0029] The punching device 4 generally comprises a punch 6 with a tool holder 7 into which punches can be introduced. By means of a drive (not shown in detail), the punch 6 can be moved along the punch stroke axis 8 together with the tool holder 7 and the punch introduced into the tool holder 7 through the working stroke and the return stroke after the working stroke, and can It is adjusted rotationally about the stamping stroke axis 8 . The laser cutting head 5 can be positioned along the laser positioning axis 9 in a manner described in more detail below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com