An integrated system of electromagnetic induction heating powder supply and powder bed additive manufacturing

An electromagnetic induction heating and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as preheating temperature in difficult-to-machine areas, complex equipment structure, aggravated warpage, etc., to reduce temperature field inhomogeneity and small conductor cross-sectional area. , the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

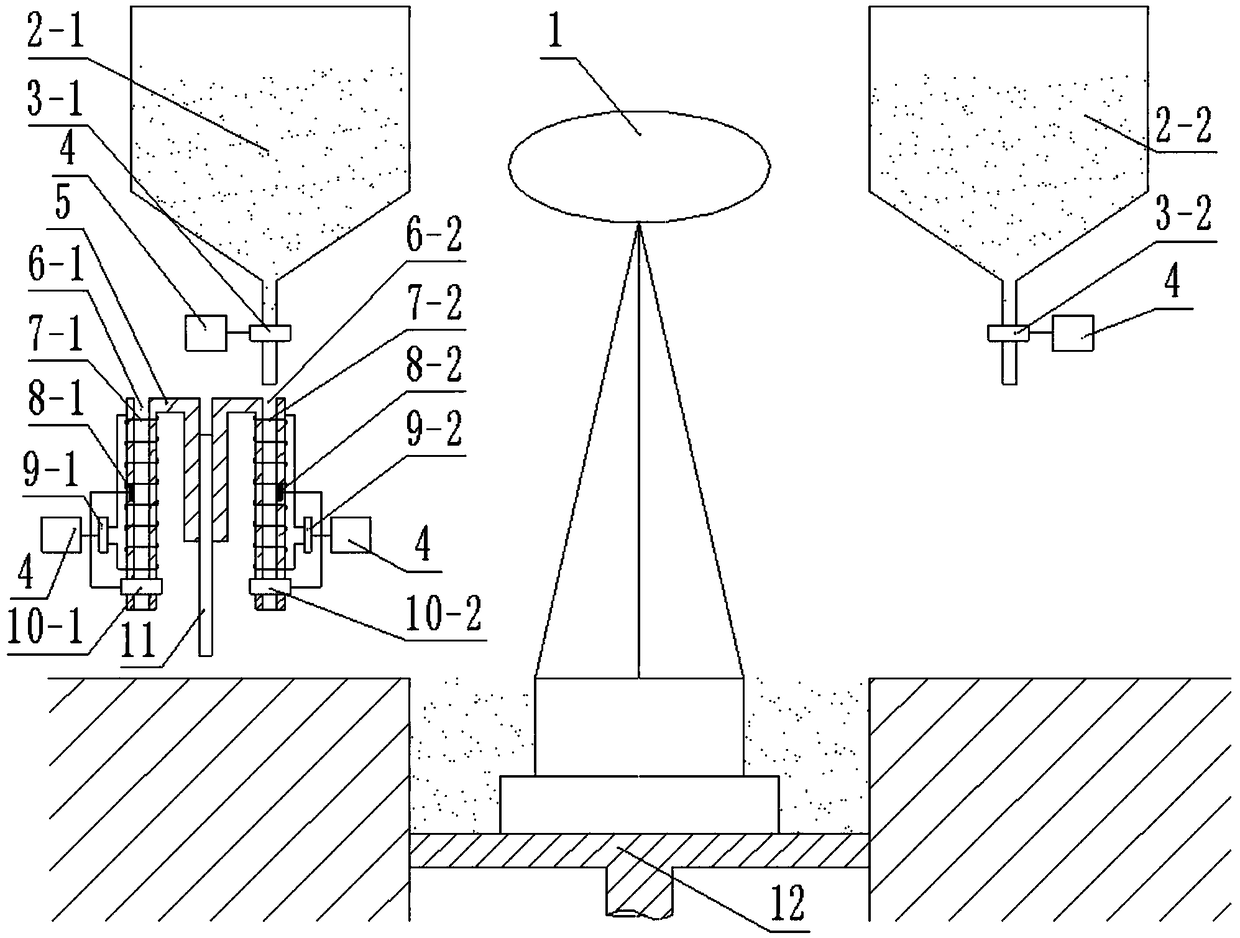

[0024] refer to figure 1 , an integrated system of electromagnetic induction heating powder supply and powder bed additive manufacturing, including a liftable forming cylinder 12, an optical path system 1 is arranged above the liftable forming cylinder 12, and the optical path system 1 adopts a laser vibrating mirror system or an electron beam, Both sides of the optical path system 1 are provided with a first powder storage cylinder 2-1 and a second powder storage cylinder 2-2, and the powder outlet of the first powder storage cylinder 2-1 is equipped with a first electromagnetic valve 3- to control powder leakage. 1. The powder outlet of the second powder storage cylinder 2-2 is equipped with a second solenoid valve 3-2 to control powder leakage. The first solenoid valve 3-1 and the second solenoid valve 3-2 are connected to the central controller 4. The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com