Petroleum resin hydrotreating method

A petroleum resin and hydrogenation treatment technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as softening point drop, unsatisfactory hydrogenation activity, coking deactivation, etc., to achieve Reduce the severity of the reaction, avoid rapid deactivation, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The preparation method of described hydrorefining catalyst is as follows:

[0083] The catalyst adopts steps such as carrier preparation, introduction of metal components, drying and roasting.

[0084] The carrier is prepared by mixing and calcining alumina and / or a precursor of alumina with silica and / or a precursor of silica. Wherein, based on the carrier, the amount of each component is finally preferably such that the carrier contains 0-30% by weight of silicon oxide and 70-100% by weight of aluminum oxide; more preferably the content of silicon oxide is 1-20% by weight , the content of alumina is 80-99% by weight. The calcination temperature is preferably 400-650°C and the calcination time is 2-15 hours, more preferably the calcination temperature is 450-600°C and the calcination time is 5-12 hours.

[0085] According to the method provided by the present invention, the method for introducing molybdenum, nickel and tungsten is preferably to introduce silicon oxid...

Embodiment

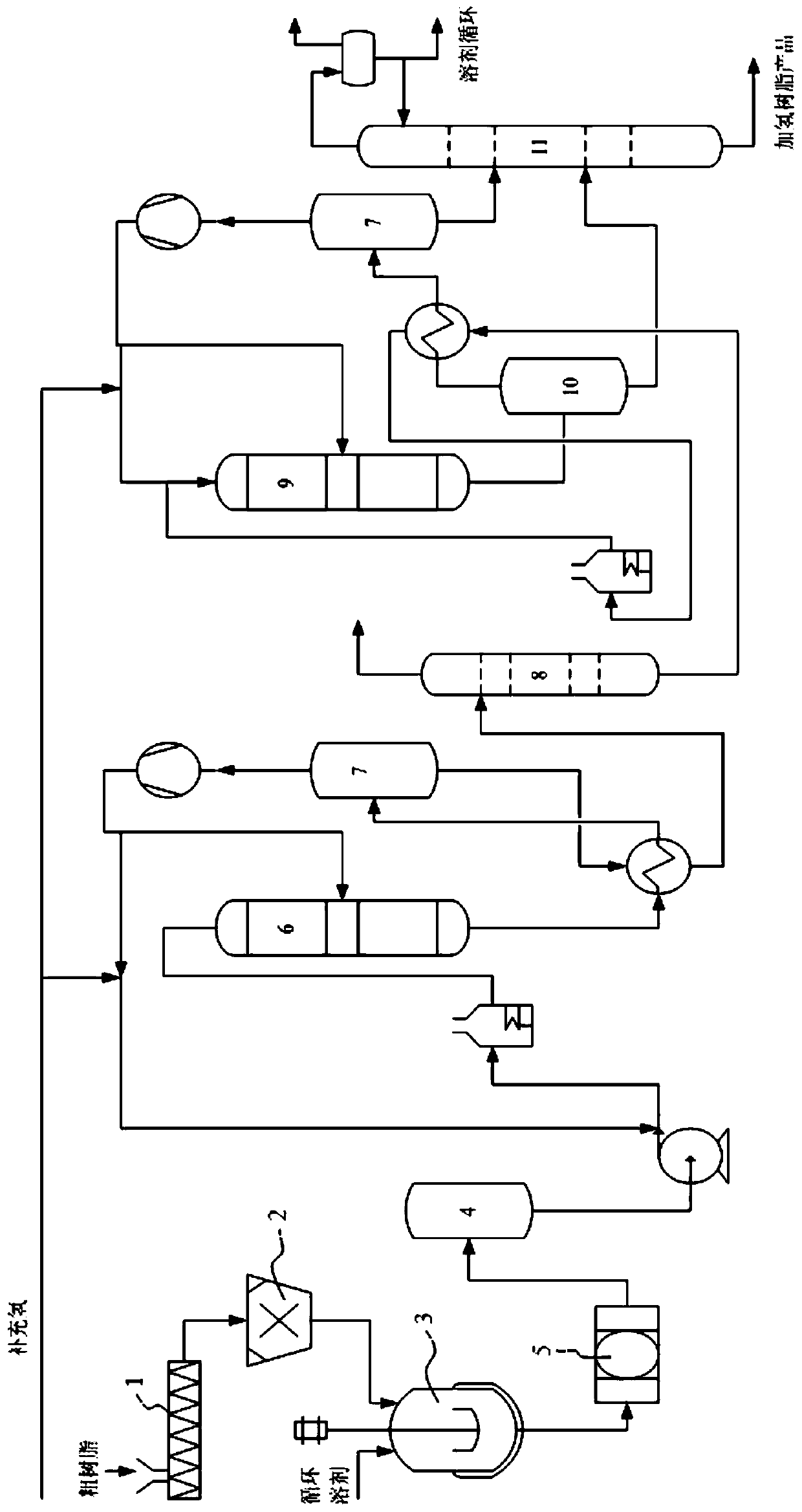

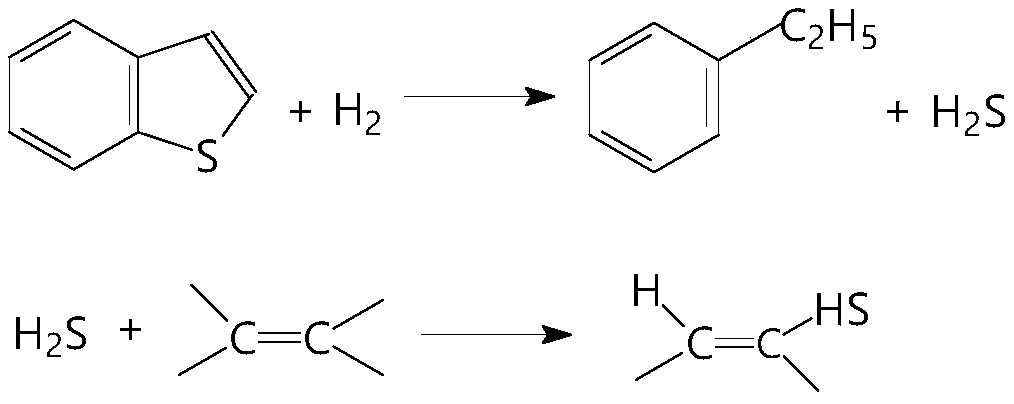

[0120] Using the two-stage hydrogenation process provided by the present invention, the first stage uses a combination of non-precious metal catalysts to mainly remove sulfur, chlorine, and colloids. Most of the olefins are saturated, and some benzene rings can also be hydrogenated and saturated. Through the first stage of hydrogenation, the hue of the resin has been greatly improved, and it is basically close to water white. In the case that the market does not have strict requirements on the aromatic content of hydrogenated petroleum resin products, relying on the first stage of hydrogenation can obtain high quality The product. Then, through the second-stage hydrogenation, the benzene ring of the first-stage product is continuously hydrogenated and saturated to obtain a high-grade, high-quality product with a watery white color.

[0121] In this embodiment, a Ni-Mo-W three-way hydrorefining catalyst (main catalyst) and its combination with a protective agent and a sweetenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com