Central oil fume purification system and real-time automatic control mode thereof

A kind of oil fume purification and central technology, applied in heating methods, oil fume removal, household heating and other directions, can solve the problems of flue cracking, oil fume entering the kitchen, negative impact on the kitchen environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

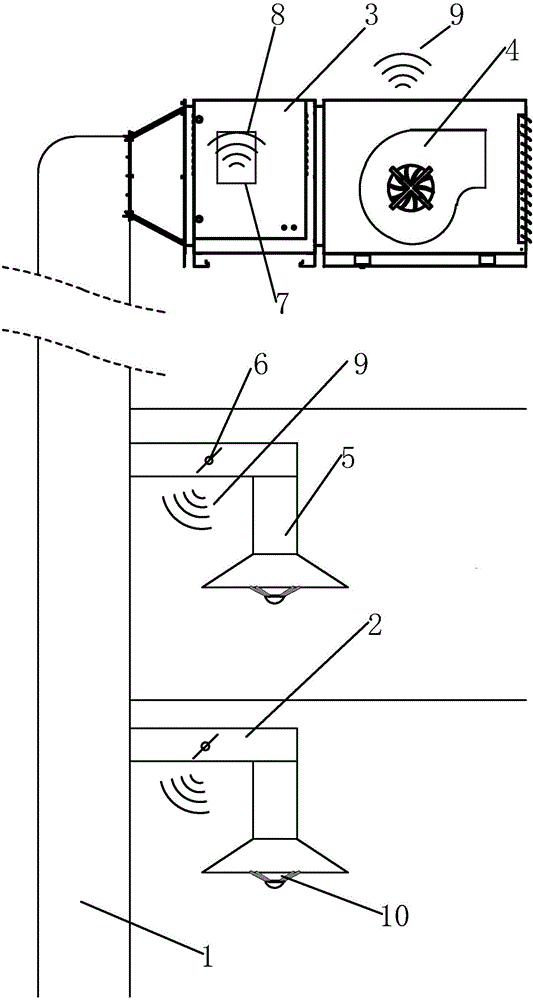

[0022] Such as figure 1 Shown is a central oil fume purification system. The system is installed in multi-storey or high-rise buildings, including the public flue 1 from the ground floor to the top floor, and a smoke collection hood 5 is installed above the stove in the kitchen of each floor, and the smoke collection hood communicates with the public flue through a connecting pipe 2 . A filter screen 10 is arranged on the fume collecting hood. A damper 6 is arranged in the connecting pipe, and the valve plate of the damper is hinged on the inner wall of the connecting pipe in a manner that can only be opened downstream, and its shape is adapted to the cross-sectional shape of the connecting pipe. The top of the public flue is located above the roof, and is connected to the oil fume purifier 3 and the fan 4 in sequence. This system is also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com