Touch display device and preparation method for same

A touch display and touch sensing layer technology, which is applied in the direction of instrument, electrical digital data processing, and data processing input/output process, etc., can solve problems such as inability to plate touch sensing patterns, polarizers and alignment films that do not have high temperature resistance, etc. , to achieve the effect of saving material and assembly costs, easy single-layer bridging structure, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The touch display device provided by the present invention can be used as a display terminal with a touch interaction form such as a mobile phone and a tablet computer.

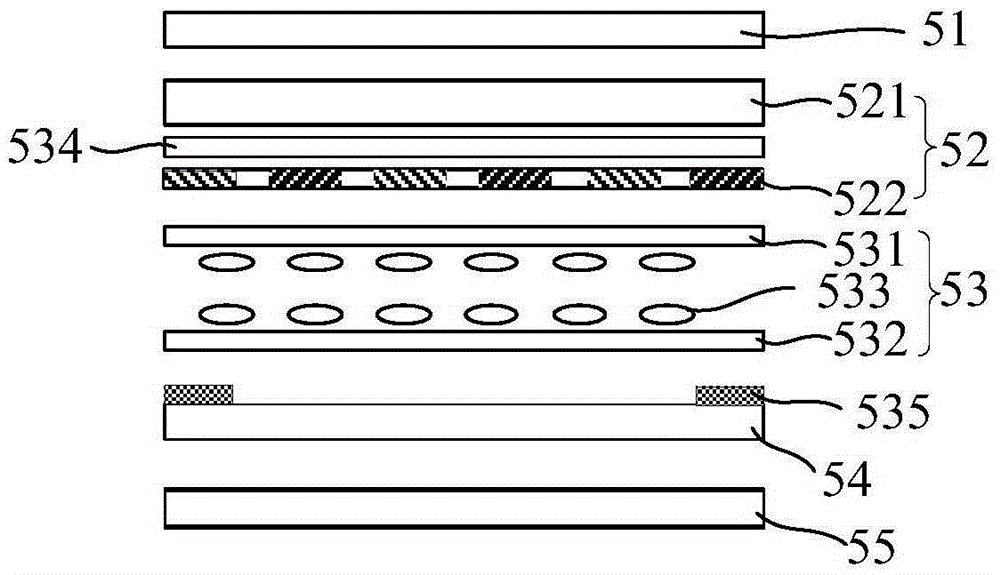

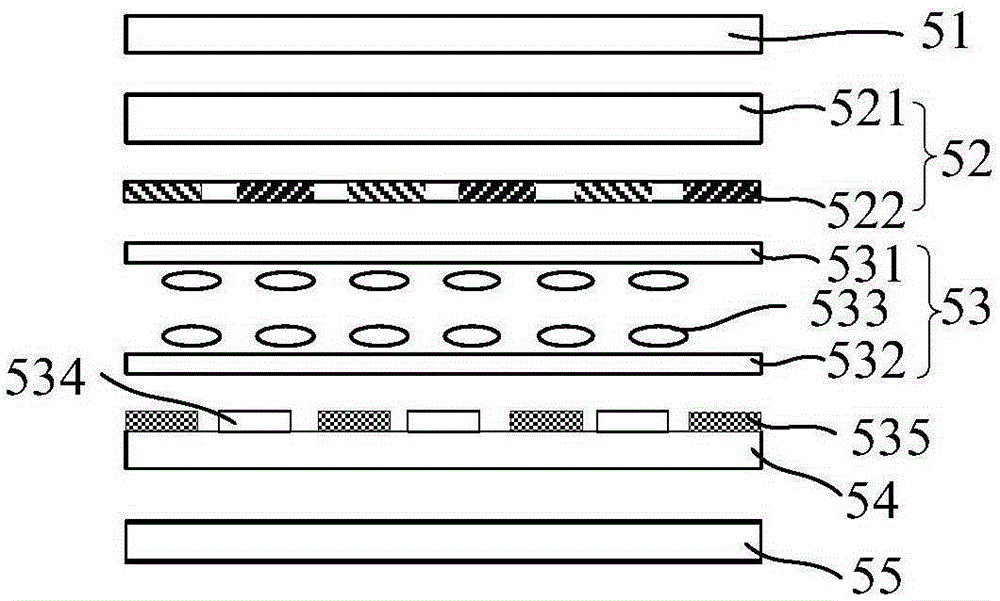

[0033] Such as figure 1 As shown, the touch display device includes an upper polarizer 51 , a filter 52 , a liquid crystal layer 53 , a substrate 54 and a lower polarizer 55 arranged in sequence.

[0034] The filter 52 includes a substrate 521 and a filter film 522 disposed on the lower surface of the substrate 521 . The orientation "upper surface" and "lower surface" of related components in the present invention are determined according to how close the touch display device is to the user when its components are in use. "Upper surface" means that the components in the touch display device are close to each other. The surface of the user, the "lower surface" refers to the surface where the elements in the touch display device are away from the user.

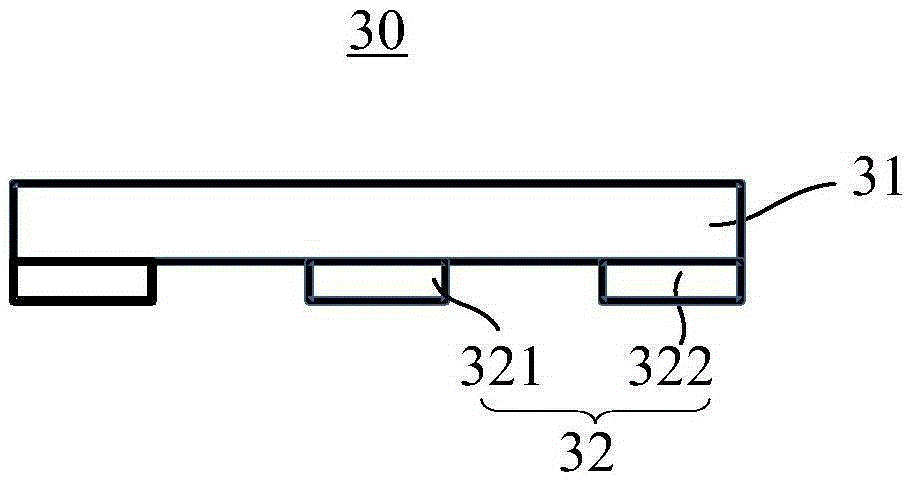

[0035] The liquid crystal layer 53 includes an u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com