Rotary heating furnace

A heating furnace and furnace body technology, applied in the field of furnace or stove, can solve the problem that the coal in the furnace is not easy to burn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

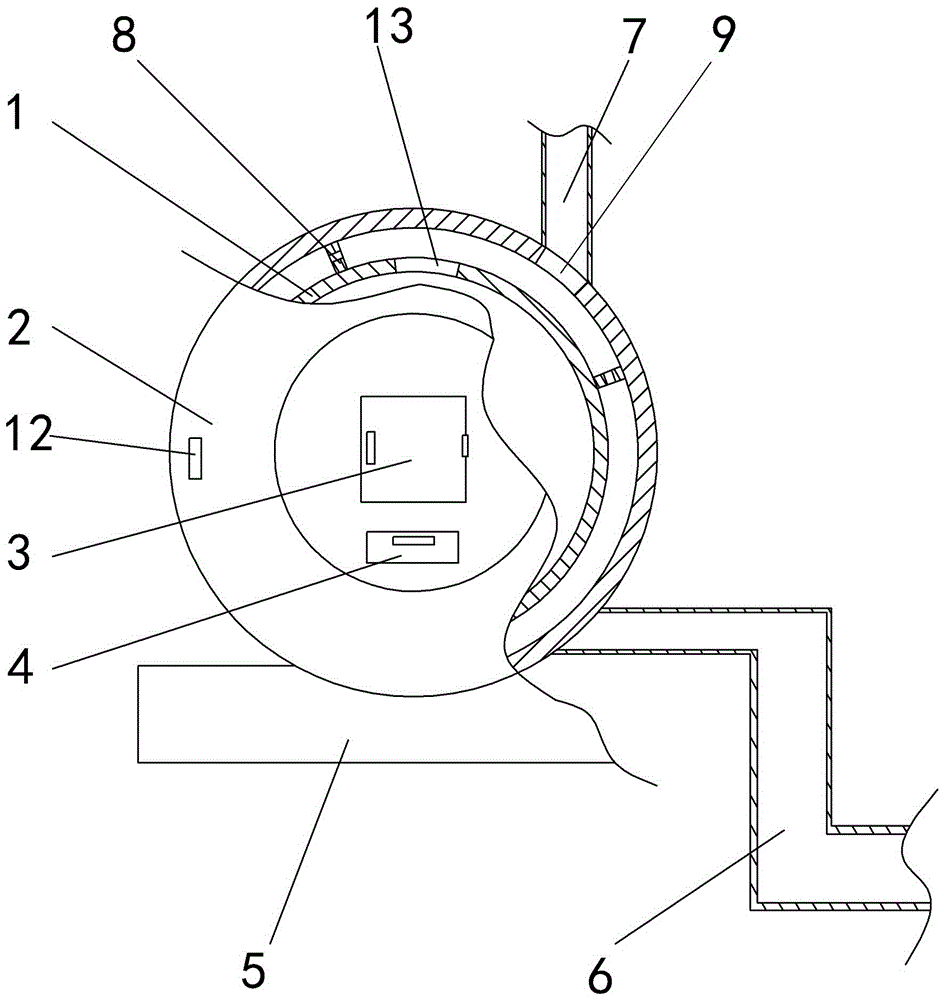

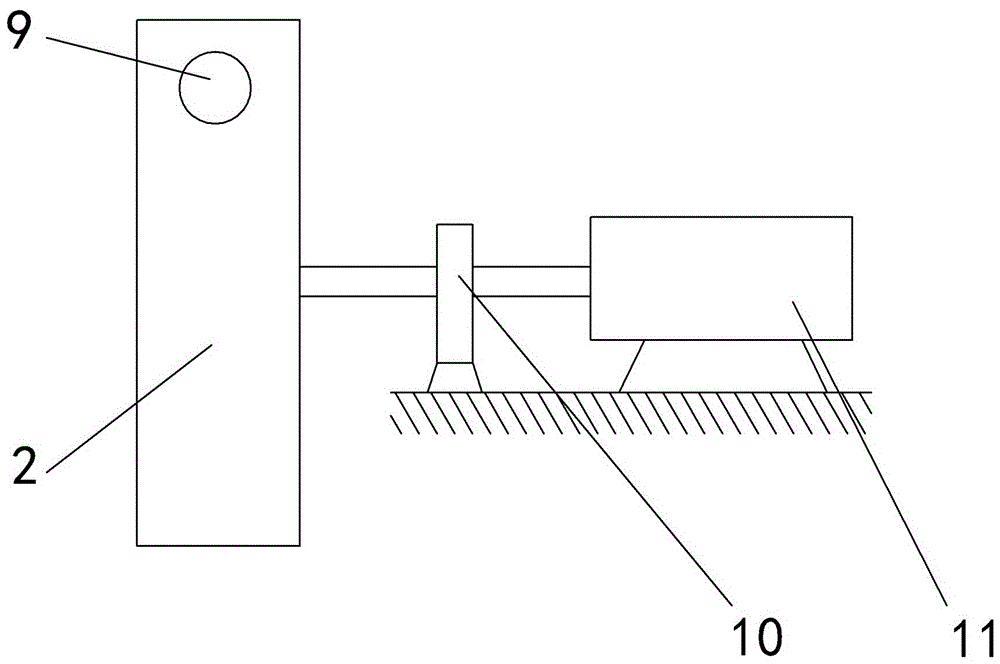

[0018] Embodiment: the rotary heating stove in this scheme, as figure 1 As shown, it includes a furnace body 2, a furnace 1 located in the furnace body 2, a motor 11 that drives the furnace body 2 to rotate in a vertical plane, and a brake 10. A rib plate 8 with a through hole is provided between the furnace body 2 and the furnace 1. , The furnace body 2 is processed with a feed port, one side of the feed port is hinged with a feed door 3, the furnace body 2 is processed with a slag discharge port, and a slag collection box 4 is installed in the slag discharge port. Such as figure 2 As shown, the motor 11 is connected to the furnace body 2, the brake 10 acts on the motor 11, and the furnace base 5 is installed below the furnace body 2. Furnace 1 is provided with a first discharge port 13 for discharging flue gas, furnace body 2 is provided with a second discharge port 9 for discharging flue gas, and a first vertical flue gas discharge pipe 7 is provided above furnace body 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com