Laser cladding powder for 1cr15ni4mo3n steel and its preparation method

A laser cladding, powder technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of wetting characteristics, melting point and physical and chemical compatibility with large differences, cladding interface pores Inclusion of micro-cracks, multi-metallurgical defect micro-cracks and other problems, to achieve the effects of excellent bonding strength, purification of melt and grain boundaries, and reduction of composition and structure segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

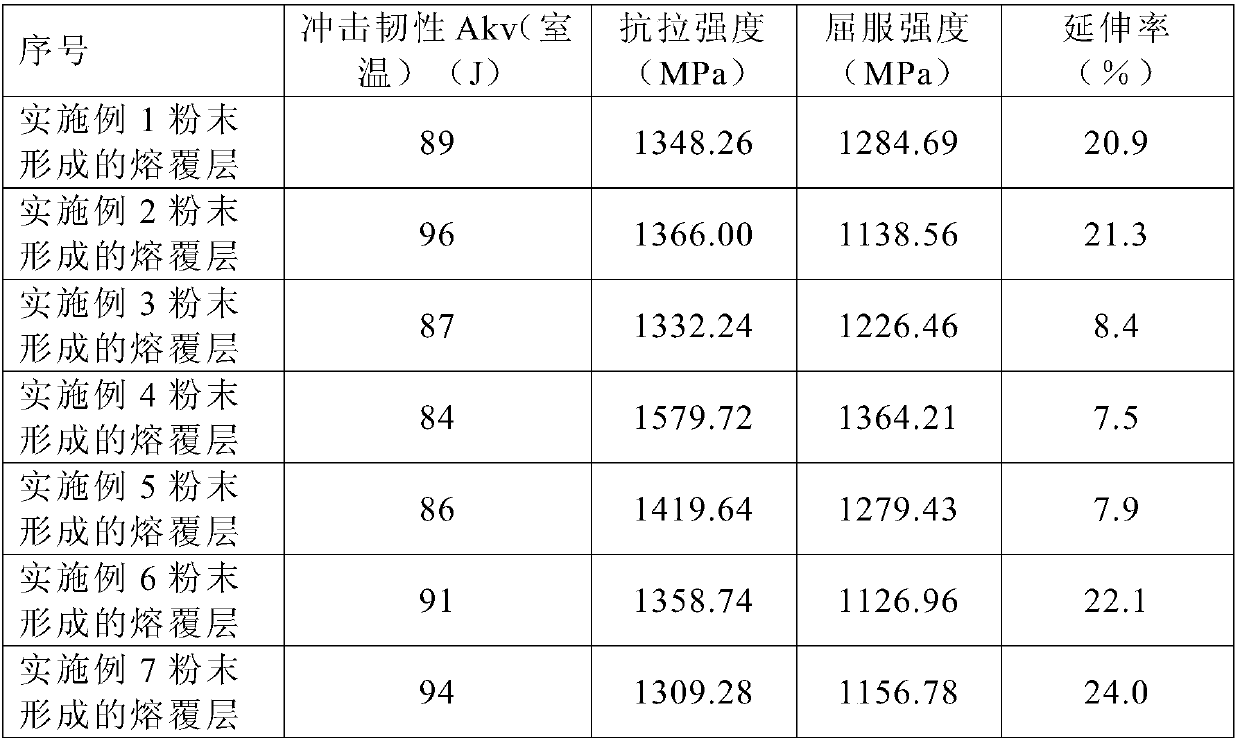

Examples

Embodiment 1

[0034] 1Crl5Ni4Mo3N steel laser cladding powder, the amount of each component in the 1Crl5Ni4Mo3N steel laser cladding powder is by weight percentage: C 0.09%, Cr 13.2%, Ni 4.1%, Mo 2.2%, Mn 0.47%, Si 0.10 %, N0.03%, B 0.02%, La 0.006%, S 0.010%, P 0.014%, and the balance is iron.

[0035] The specific preparation method is:

[0036] Step 1: Ingredients: Prepare the raw material 1Crl5Ni4Mo3N round bar and high-purity Fe / Si / B / La alloy powder according to the weight percentage content of each component in the above-mentioned laser cladding powder;

[0037] Step 2: Melting: put the raw materials prepared in Step 1 into a high-vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1400°C, and the holding time is 10 hours to obtain an alloy melt;

[0038] Step 3: atomization: further atomize the alloy solution obtained in step 2, the atomization medium is an argon atmosphere at -15°C, and the atomization pressure is 5MPa; hydrogen ...

Embodiment 2

[0041] 1Crl5Ni4Mo3N steel laser cladding powder, the amount of each component in the 1Crl5Ni4Mo3N steel laser cladding powder is by weight percentage: C 0.09%, Cr 13.2%, Ni 4.5%, Mo 2.2%, Mn 0.47%, Si 0.15 %, N0.03%, B 0.05%, Ce 0.01%, S 0.010%, P 0.014%, and the balance is iron.

[0042] The specific preparation method is:

[0043] Step 1: Ingredients: Prepare the raw material 1Crl5Ni4Mo3N round bar and high-purity Fe / Si / B / Ce alloy powder according to the weight percentage content of each component in the above-mentioned laser cladding powder;

[0044] Step 2: Melting: Put the raw materials prepared in Step 1 in a high vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1400°C, and the holding time is 12 hours to obtain an alloy melt;

[0045] Step 3: Atomization: further atomize the alloy solution obtained in step 2, the atomization medium is an argon atmosphere at -14°C, and the atomization pressure is 5.5MPa; hydrogen g...

Embodiment 3

[0048] Laser cladding powder for 1Crl5Ni4Mo3N steel, the amount of each component in the laser cladding powder for 1Crl5Ni4Mo3N steel is: C 0.09%, Cr 13.2%, Ni 5.1%, Mo 2.2%, Mn 0.47%, Si 0.25 %, N 0.03%, B 0.10%, La 0.01%, Ce 0.01%, S 0.010%, P 0.014%, and the balance is iron.

[0049] The specific preparation method is:

[0050] Step 1: Ingredients: Prepare the raw material 1Crl5Ni4Mo3N round bar and high-purity Fe / Si / B / La / Ce alloy powder according to the weight percentage content of each component in the above-mentioned laser cladding powder;

[0051] Step 2: Melting: put the raw materials prepared in Step 1 into a high vacuum protection electric furnace for melting under the protection of argon, the melting temperature is 1500°C, and the holding time is 10 hours to obtain an alloy melt;

[0052] Step 3: Atomization: further atomize the alloy solution obtained in step 2. The atomization medium is an argon atmosphere at -13°C, and the atomization pressure is 5.5MPa; The vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com