An even and rapid interlayer adhering method for carbon fiber heat-insulating hard felt

A technology of thermal insulation hard felt and carbon fiber, which is applied in the field of uniform and rapid bonding between layers of carbon fiber thermal insulation hard felt, which can solve the problems of easy delamination of the amount of adhesive, high labor intensity of workers, product pollution, etc., and achieve product strength and density guarantee , Product strength and density are good, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

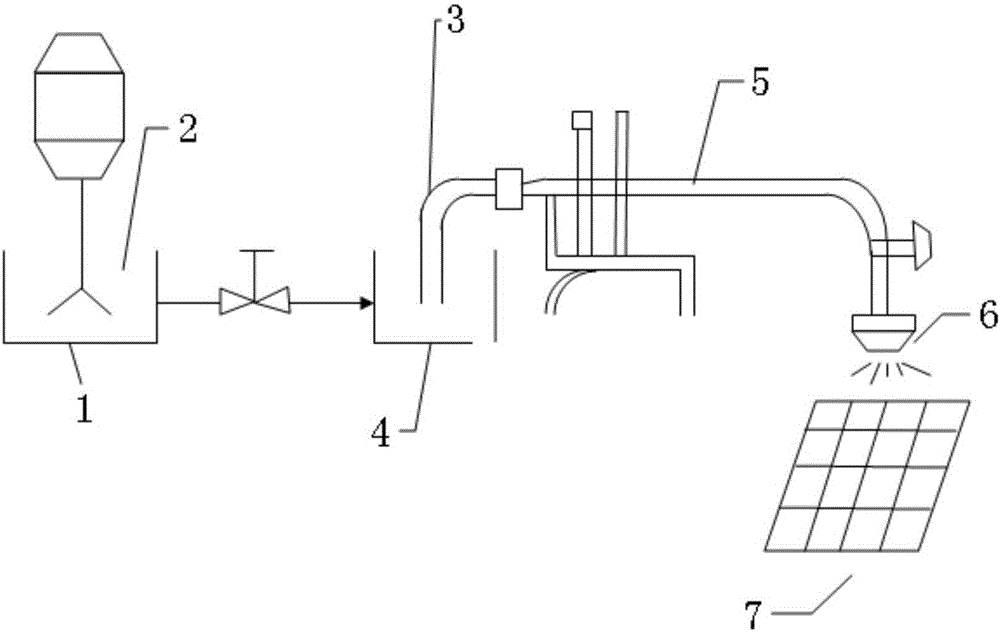

[0018] A method for evenly and quickly bonding between layers of carbon fiber thermal insulation hard felt, comprising the following steps:

[0019] Step 1: Configure the adhesive 2 according to the following weight ratio: diluent: resin: graphite powder = 65:25:10, stir continuously in the mixing tank 1 for 20 minutes, put it into the rubber bucket 4 for use, and the diluent has a concentration of 95 % industrial alcohol, when the temperature is lower than 10 ℃, it must be equipped with a constant temperature water bath heating device;

[0020] The second step: adjust the viscosity of the adhesive 2: the viscosity is controlled at 1500cps;

[0021] Step 3: At the glue spraying site, use the pneumatic graphite emulsion spray gun 5 to spray the adhesive glue on the carbon fiber insulation hard felt layer 7, first connect the compressed air connector of the graphite emulsion spray gun 5, and place the other port on the glue In barrel 4, the spray angle of the spray gun is 75 de...

Embodiment 2

[0025] The steps of a method for uniform and rapid bonding between carbon fiber thermal insulation hard felt layers described in this embodiment are the same as in Embodiment 1, and the different technical parameters are:

[0026] 1) The adhesive viscosity in the second step is controlled at 1700cps;

[0027] 2) In the third step, the height of the spray gun from the carbon fiber felt is 300mm, the air pressure of the spray gun is 0.3Mpa, and the spray angle of the spray gun is 90 degrees;

[0028] 3) In the fourth step, the amount of glue sprayed is controlled at 0.45kg / ㎡.

Embodiment 3

[0030] The steps of a method for uniform and rapid bonding between carbon fiber thermal insulation hard felt layers described in this embodiment are the same as in Embodiment 1, and the different technical parameters are:

[0031] 1) The adhesive viscosity in the second step is controlled at 2000cps;

[0032] 2) In the third step, the height of the spray gun from the carbon fiber felt is 400mm, the air pressure of the spray gun is 0.4Mpa, and the spray angle of the spray gun is 110 degrees;

[0033] 3) In the fourth step, the amount of glue sprayed is controlled at 0.4kg / ㎡.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com