Machine leg welding equipment for compressor and use method of machine leg welding equipment

A compressor and machine foot technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding position deviation, reduce production accuracy, reduce production efficiency, etc., to reduce assembly errors, improve The effect of production efficiency, quick alignment and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

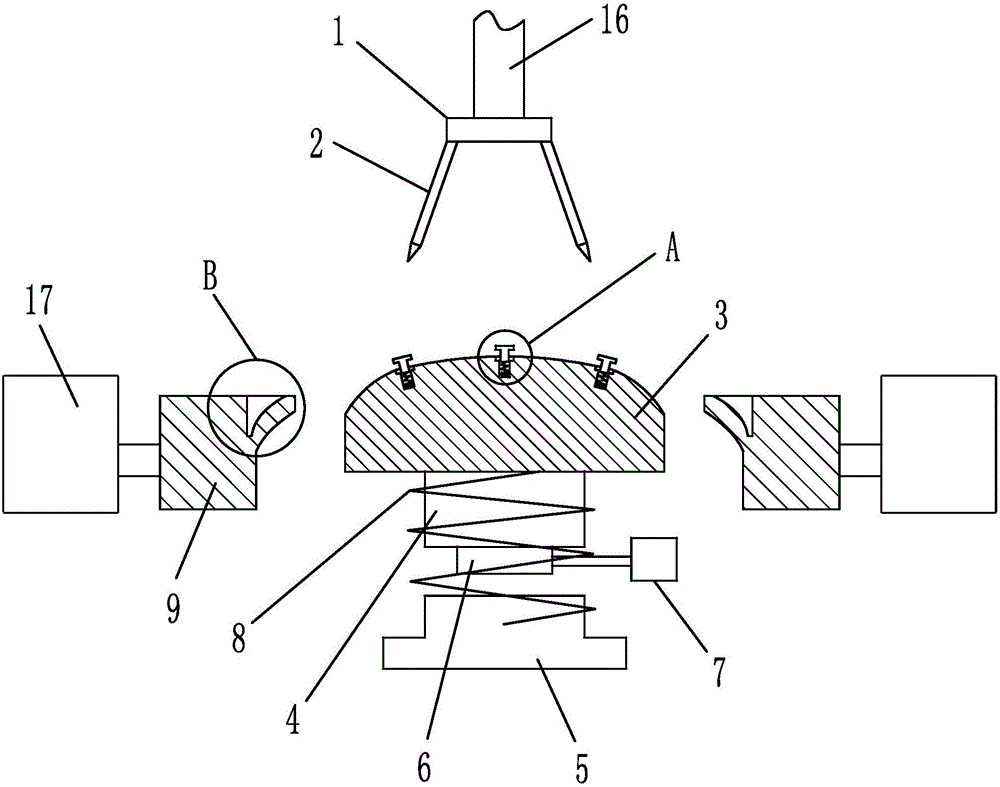

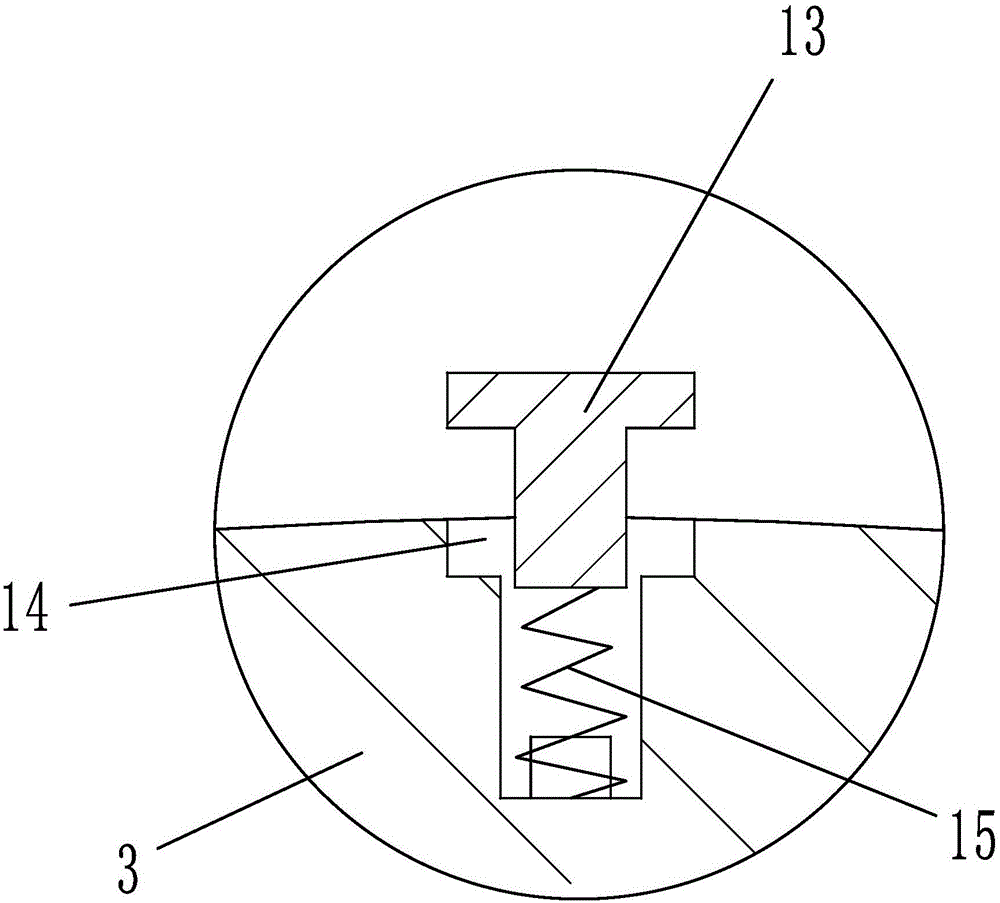

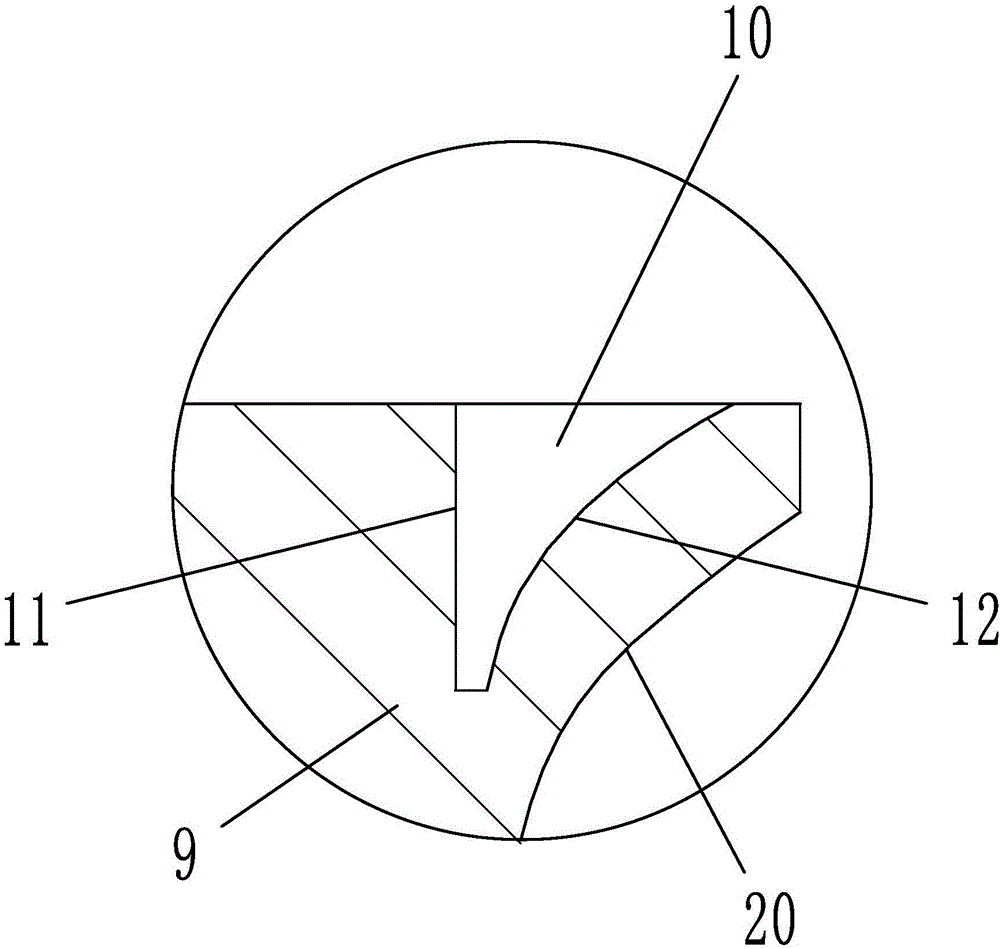

[0018] Embodiment 1: as figure 1 , 2, 3, and 4, a compressor foot welding equipment, including positioning head 3 cooperating with the inner surface of the casing 18, claws 9 positioned on both sides of the positioning head and a welding mechanism positioned above the positioning head, the positioning head A column 4 is arranged on the axis of the lower end surface, a positioning column 5 is arranged coaxially below the column, a positioning spring 8 is set on the outside of the column and the positioning column, a vibration column 6 is arranged at the bottom of the column, and a vibrator 7 is connected to the vibration column; A guide surface 20 matching the shape of the outer surface of the positioning head is provided on the end surface close to the positioning head, and a positioning groove 10 for fixing the machine foot 19 is provided on the edge of the upper end surface of the claw close to the positioning head, and the positioning groove is far from the end of the posit...

Embodiment 2

[0021] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Image 6 , 7 As shown, the positioning head includes a left half head 31 and a right half head 32, and the middle part of the left half head and the right half head is provided with a positioning hole 26, and the positioning hole is provided with a positioning shaft 27 that cooperates with the positioning hole clearance. Position straight face 28 and sliding arc surface 29, the section of positioning hole is " D " font. The positioning head includes a left half head and a right half head. There are positioning holes in the middle of the left half head and the right half head. The positioning shaft is arranged in the positioning hole to fit with the positioning hole. The left half head and the right half head can be positioned through The shaft changes the distance between the two, which in turn changes the length of the positioning head, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com