Storage shelf spraying system

A sprinkler system and shelf technology, applied in medical science, dentistry, dental drilling, etc., can solve the problems of unfavorable oil transfer, large fire water consumption, low fire suppression efficiency, etc., to avoid explosion, speed up operation, increase The effect of large fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

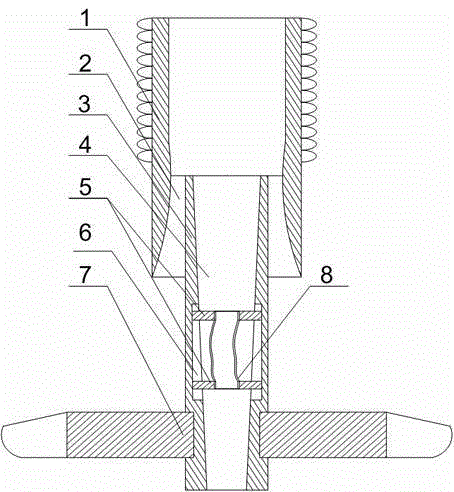

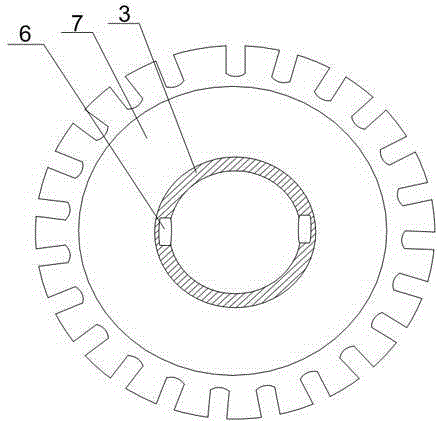

[0020] Such as figure 1 with figure 2 As shown, this embodiment includes a fixed cylinder 1, in which a direct current pipe 3 communicating with it and extending outward is installed, and there are two arc-shaped sides between the direct current pipe 3 and the inner wall of the fixed cylinder 1 To the flow channel 2, the direct-flow pipe 3 is provided with a direct-flow waterway 4, and a movable groove 6 is opened in the middle of the direct-flow waterway 4, and two flow-limiting plates 5 distributed up and down are slidably arranged in the movable groove 6, and the direct-flow waterway The upper and lower parts of 4 are connected through the hoses 8 whose ends respectively pass through the two restrictor plates 5, and the length of the hose 8 is greater than the distance between the two restrictor plates 5; The matching splash plate 7 is rotatably arranged on the outer wall of the extension end of the straight pipe 3, and the outer edge of the upper surface of the splash pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com