Fault Detection Method for Continuous Processes Based on Integrated Kernel Local Preserving Projection

A technology that maintains projection locally and detects faults. It is applied to computer components, data processing applications, and instruments. It can solve problems such as different parameters and non-unique faults, and achieve the effect of improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with examples.

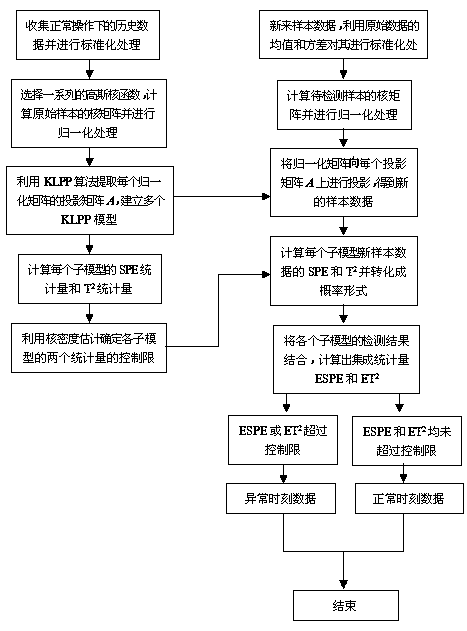

[0016] The invention uses the Gaussian kernel function to preprocess the continuous process data, and extracts the nonlinear information of the original data. Based on the preprocessing, the local structure of the original data is preserved using locality-preserving projections. By selecting Gaussian kernel functions with different kernel parameters to solve the problem that parameter selection affects fault detection results, multiple sub-models are established, and Bayesian decision-making and ensemble learning methods are used to combine each detection result for continuous process fault detection. This technology solves the problem that the traditional KLPP method selects the same kernel parameters when dealing with different faults.

[0017] Fault detection technology based on integrated kernel local-holding projection: In order to detect process faults, it is necessary to use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com