Liquid crystal panel and liquid crystal panel photo-alignment method

A liquid crystal panel and optical alignment technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of unable to discharge cured wires and increase the number of cured wires, so as to overcome space constraints, increase space, and signal delay difference is small Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

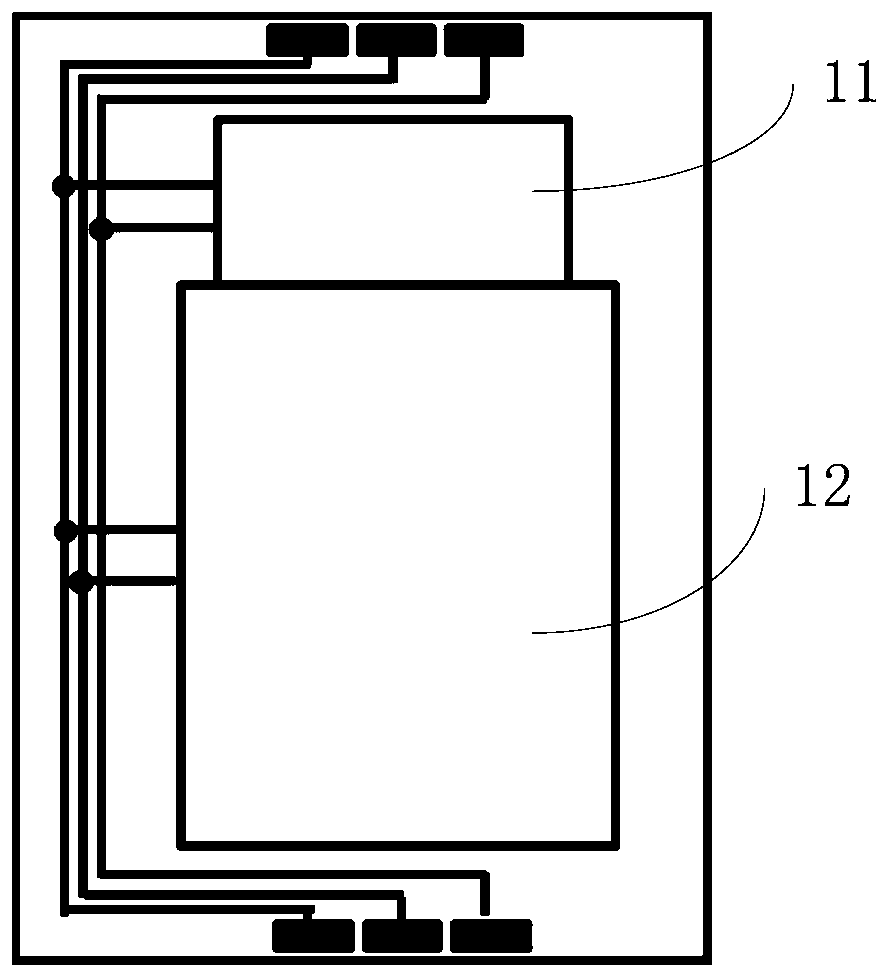

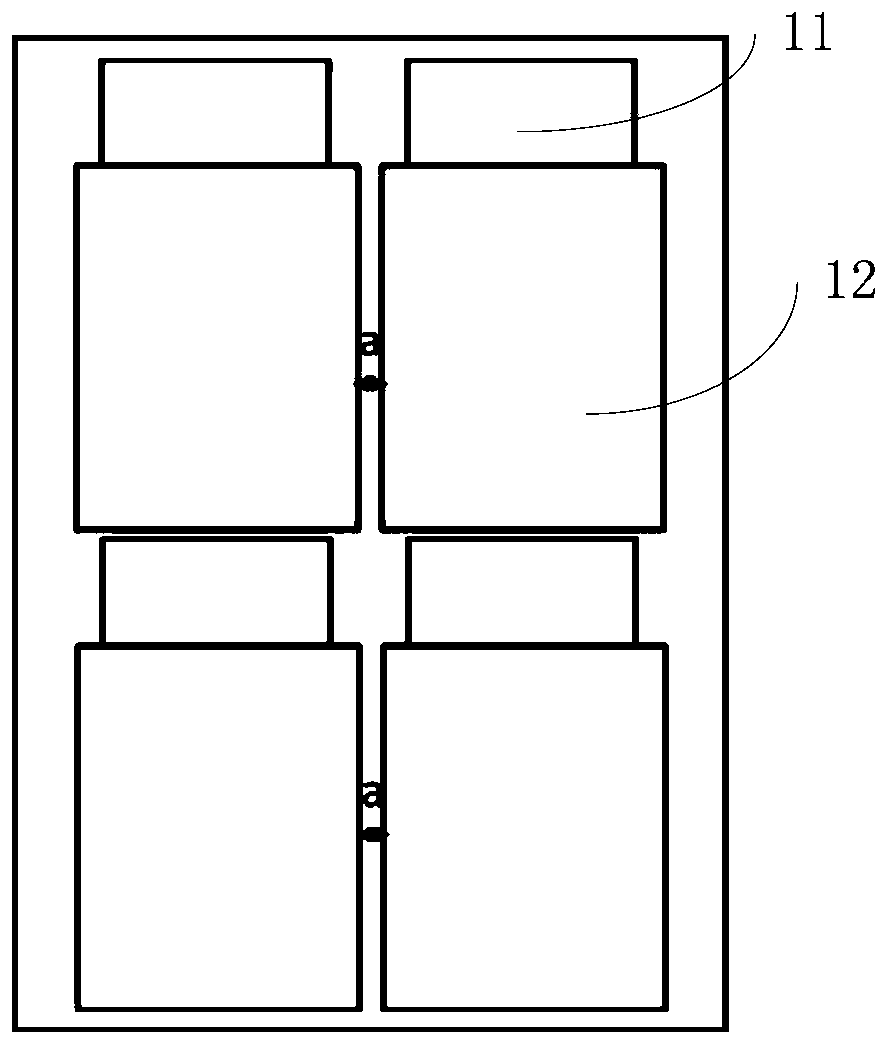

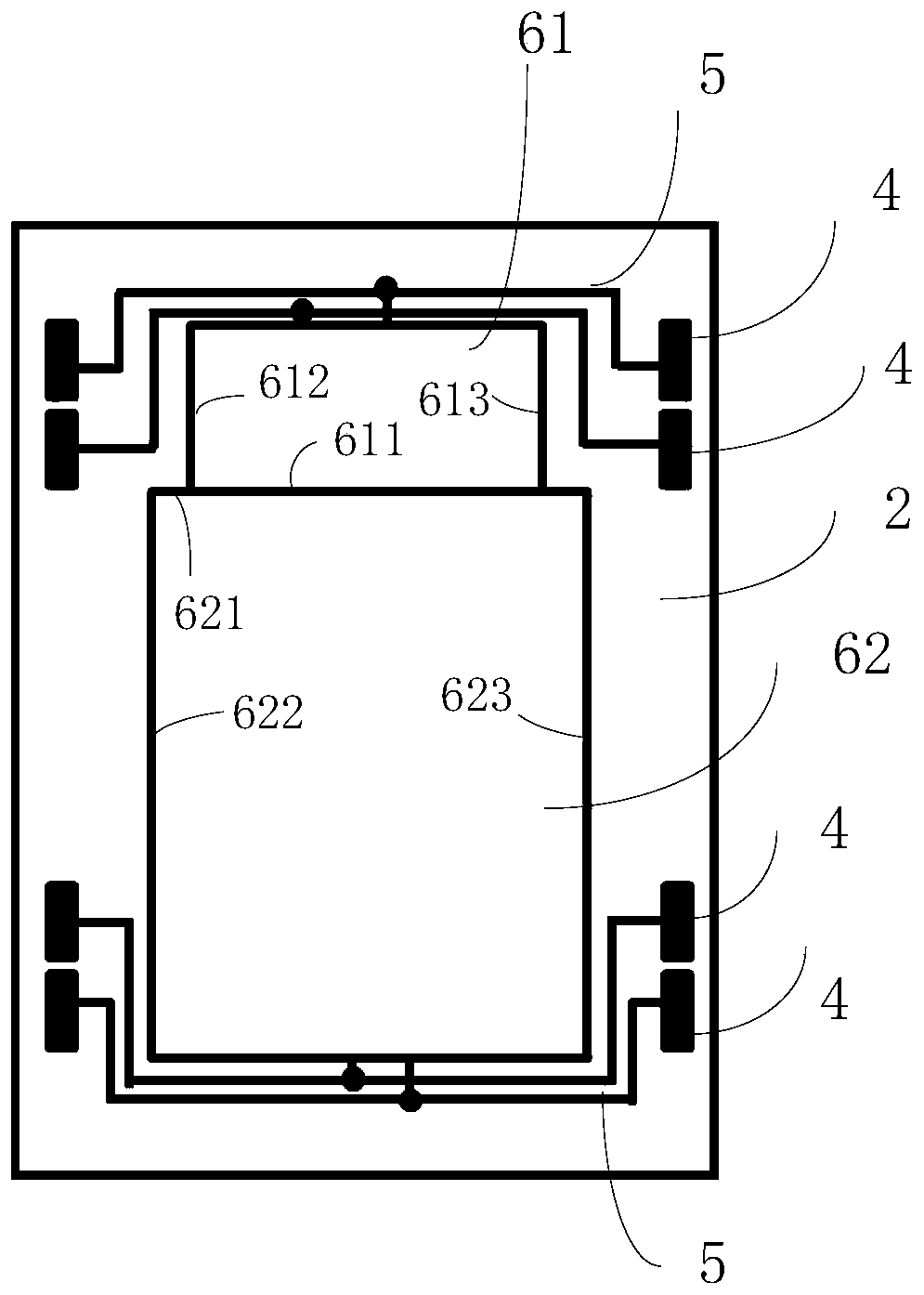

[0031] Please refer to image 3 , an embodiment of the present invention provides a liquid crystal panel, including: a color filter substrate 1, an array substrate 2, a curing connection terminal 4, a curing wiring 5 and a chipset, wherein the curing connection terminal 4, the curing wiring 5 and the chipset are all Arranged on the array substrate 2; the cured wiring 5 connects the cured connection terminal 4 with the chipset; the cured connection terminal 4 is used to connect the array substrate 2 and the color filter substrate 1; the chipset includes at least a first chip 61 and a second chip 62 , Optionally, the area of the first chip 61 is smaller than that of the second chip 62; for the first chip 61 and the second chip 62, corresponding curing connection terminals 4 and curing traces 5 are respectively provided; during curing and voltage application, Curing Signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com