Washing machine environment-friendly water-saving working method and washing machine thereof

A working method and technology of a washing machine, applied in the field of washing machines, can solve problems such as poor design of the shape of the chute, achieve fewer sealing links, prevent secondary pollution, and have good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

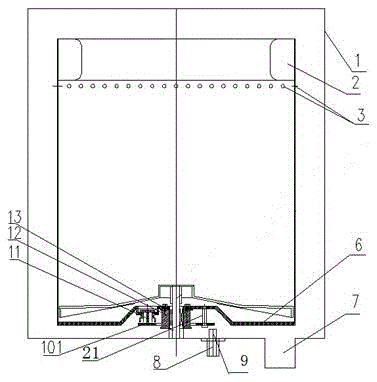

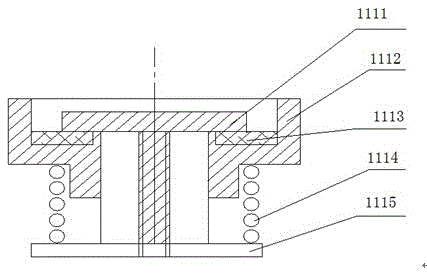

[0035] Combined graph 1 As shown, this embodiment provides an environment-friendly water-saving washing machine, and the washing machine includes an outer tub 1 and inner barrel 2 , the outer barrel of the 1 There is a drain at the bottom of the bucket 7 , the inner barrel of the 2 It is an integral water storage barrel, and the inner barrel 2 The uppermost end is provided with a balance ring, and the lower end of the balance ring is provided with a 2 A ring of water throwing holes on the central axis 3 , inner barrel 2 Concentrically mounted on the outer barrel 1 inside, the inner barrel of the 2 A deceleration clutch is arranged below, and the power output shaft above the deceleration clutch and the inner barrel 2 Bottom connection, and for the inner barrel 2 transmission, and at the same time decelerate the power take-off shaft above the clutch and the upper shaft sleeve 12 Clearance fit, inner barrel flange 6 Concentrically mou...

Embodiment 2

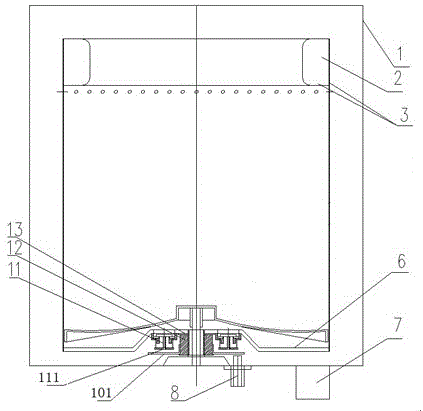

[0051] as shown in the picture 3 As shown, others are the same as in the embodiment 1 , the difference is that the annular push plate 101 with upper sleeve 12 There is a concentric gap fit between them, which can move along the axial direction of the upper sleeve, and the annular push plate 101 Located on inner drum flange 6 Bottom; ring push plate 101 The structure is changed to the structure shown in the figure, and the second guide post is omitted 21 . The advantage of this embodiment is that the second guide post is omitted 21 , thus simplifying the device without affecting the normal operation of the washing machine and ensuring the original functions.

Embodiment 3

[0053] as shown in the picture 4 As shown, others are the same as in the embodiment 1 , the difference is: the manipulator is an electromagnet 8 with fork 16 , the shift fork 16 with mounted on outer barrel 1 Fork fulcrum on inner bottom 15 active connection, and the fork 16 with electromagnet 8 The corresponding position is provided with a material that can be magnetically adsorbed, and the fulcrum of the shift fork 15 with electromagnet 8 Distributed on both sides of the vertical rotation central axis of the washing machine. When the controller is working, set it on the outer tub of the washing machine 1 Electromagnet on the outside 8 Start working under the instructions of the computer board program, through the electromagnet 8 pair set on the fork 16 Pull the fork down due to the adsorption of the magnetically adsorbable material on the 16 at one end, at the same time at the fulcrum of the fork 15 Under the action of the shift fork 16 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com