Method for grafting propylene polymer with polar monomer

A technology of propylene polymer and polar monomer, applied in the field of propylene polymer grafting polar monomer, can solve the problems of many kinds of raw materials, limited polymer performance, complicated process, etc., so as to reduce costs and improve grafting. efficiency, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

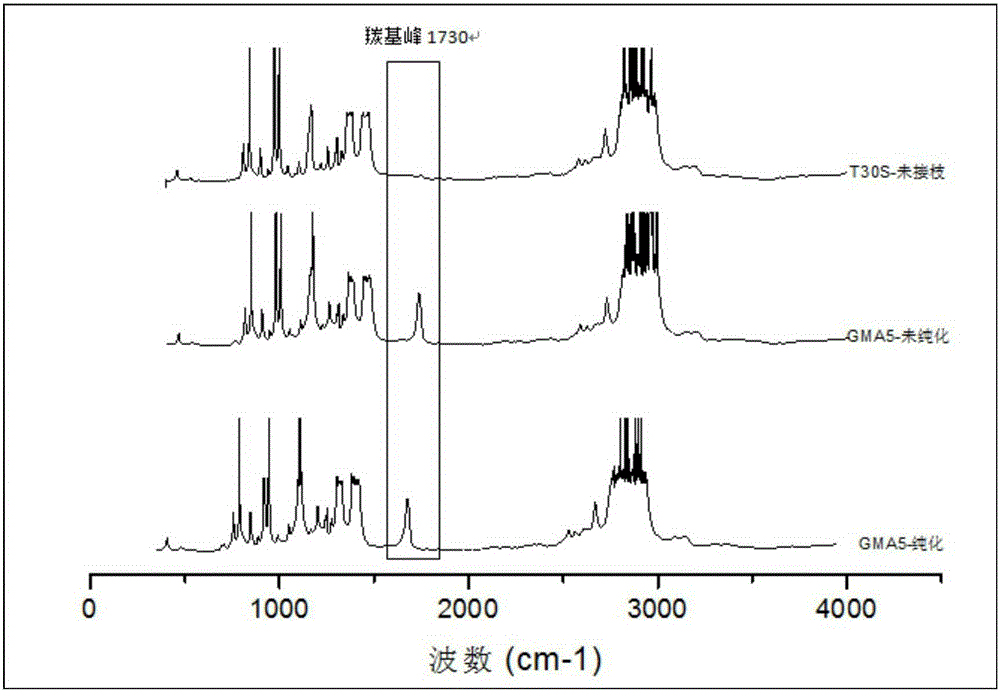

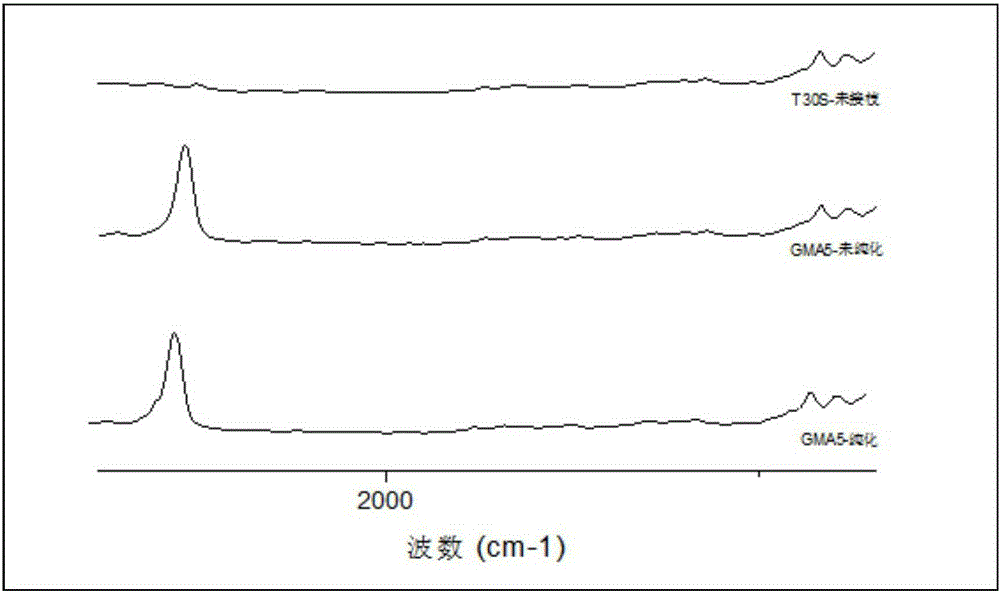

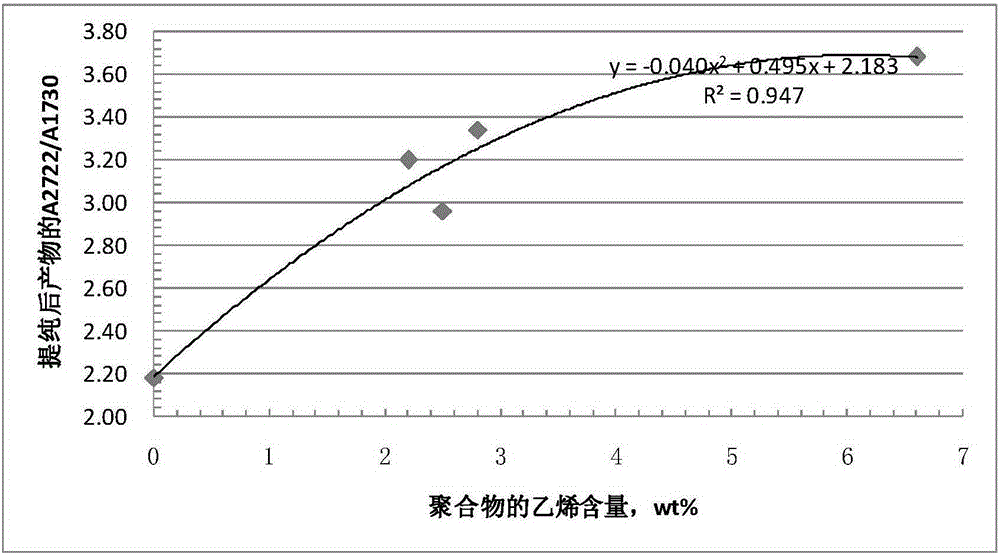

[0053] A propylene / ethylene random copolymer is used as the polypropylene matrix, wherein the ethylene content is 2.2wt%, and the melt mass flow rate is 3.6g / 10min. After sieving, 300g of particles with a particle size between 1mm and 2mm are taken.

[0054] Put it into a 2L glass kettle with a condensing device with mechanical stirring, and vacuumize it to remove oxygen. Add an acetone solution containing 0.384 g of benzoyl peroxide, stir and mix for 15 minutes, and then vacuumize to remove the acetone. Add 15g of GMA and 100ml of deoxygenated deionized water, and stir for 30 minutes to make the GMA fully infiltrate the base material. Then add 100ml of deionized water, heat to 90°C, and react for 4 hours. After the reaction, the product was filtered out, cooled, washed with deionized water for 3 times, and then fluidized and dried.

[0055] Take 2g sample, dissolve it with 100ml xylene at 140°C for 1 hour, then pour it into 250ml acetone while it is still hot, and filter it...

Embodiment 2

[0057] The polypropylene matrix was changed to a propylene / ethylene random copolymer with an ethylene content of 2.5 wt%, and other conditions were the same as in Example 1. The experimental results of A1730 / A2722 before and after purification are listed in Table 1.

Embodiment 3

[0059] The polypropylene matrix was changed to a propylene / ethylene random copolymer with an ethylene content of 2.8 wt%, and other conditions were the same as in Example 1. The experimental results of A1730 / A2722 before and after purification are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com