A preparation method of nano antimony sulfide particles under controllable conditions

An antimony sulfide and nanotechnology, which is applied in the energy field, can solve the problems of cumbersome preparation of nanometer antimony sulfide particles, and achieves the effect of being suitable for large-scale popularization and application, simple operation and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

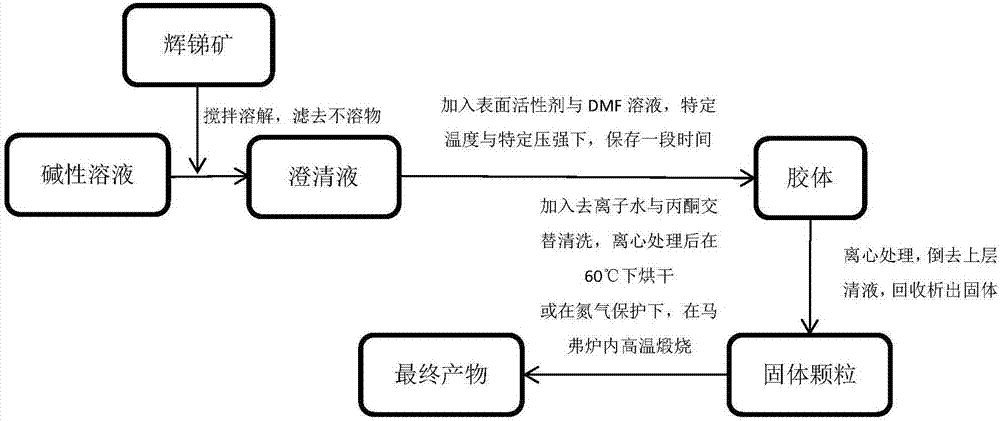

[0027] A flow chart of the method for preparing nanometer antimony sulfide particles under controllable conditions is shown in the attached figure 1 , consisting of four steps of dissolution, temperature control, precipitation and cleaning. Its specific steps include:

[0028] 1) using an alkaline solution to dissolve the antimony sulfide mineral particles;

[0029] 2) After adding a surfactant and a specific solvent, store it at a certain temperature and wait for the solid to precipitate;

[0030] 3) The precipitated solid is soaked and cleaned with deionized water or acetone, and then centrifugally dried or calcined at a high temperature in a muffle furnace under the protection of nitrogen;

[0031] In the present invention, a surfactant and a specific solution need to be added before the temperature control process to control the size and shape of the precipitated particles. After the specific solvent is added to the solution, it can not only precipitate the nano antimon...

Embodiment 1

[0052] 1) Weigh 1.2 kg of sodium hydroxide, dissolve in 20 kg of deionized water, and stir until completely dissolved;

[0053] 2) Weigh 2 kg of stibnite powder and dissolve it in the solution, add 50 kg of deionized water, stir for half an hour, and filter out the insoluble matter;

[0054] 3) Weigh 50 grams of polyethylene glycol and 2 kilograms of DMF, add them into the solution, mix well, and keep warm at 60° C. for 4 hours;

[0055] 4) Centrifuge the solution, take the precipitated solid particles, wash and soak them alternately with deionized water and acetone, and repeat the centrifugation step;

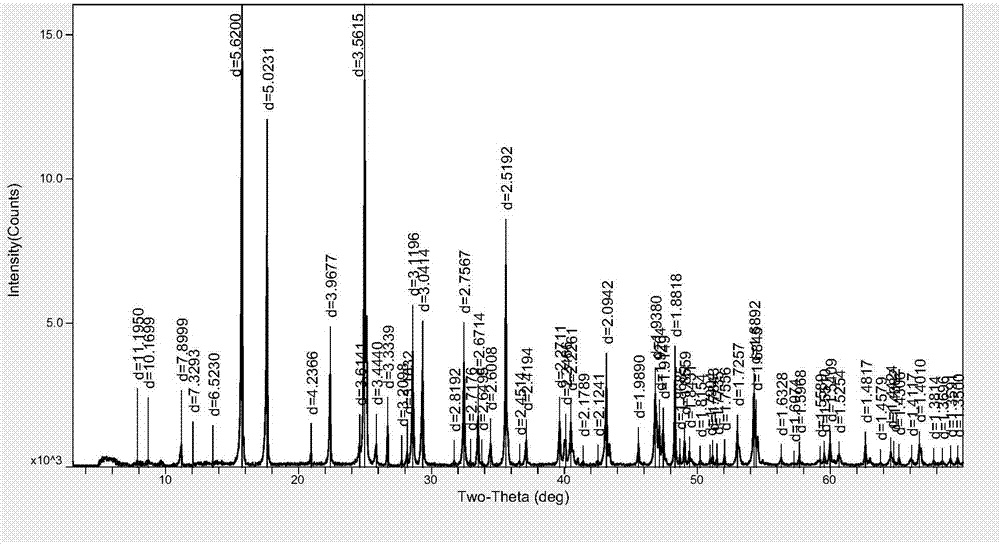

[0056] 5) Dry the solid obtained by centrifugation at 60°C, weigh 0.8574 kg, and carry out subsequent characterization experiments, and the results are as follows image 3 shown.

Embodiment 2

[0058] 1) Weigh 0.6 kg of sodium hydroxide, dissolve in 10 kg of deionized water, and stir until completely dissolved;

[0059] 2) Weigh 1 kg of stibnite powder and dissolve it in the solution, add 25 kg of deionized water, stir for half an hour, and filter out the insoluble matter;

[0060] 3) Weigh 25 grams of cetyltrimethylammonium bromide and 1 kilogram of DMF, add them into the solution, mix well, and keep warm at 80° C. for 4 hours;

[0061] 4) Centrifuge the solution, take the precipitated solid particles, wash and soak them alternately with deionized water and acetone, and repeat the centrifugation step;

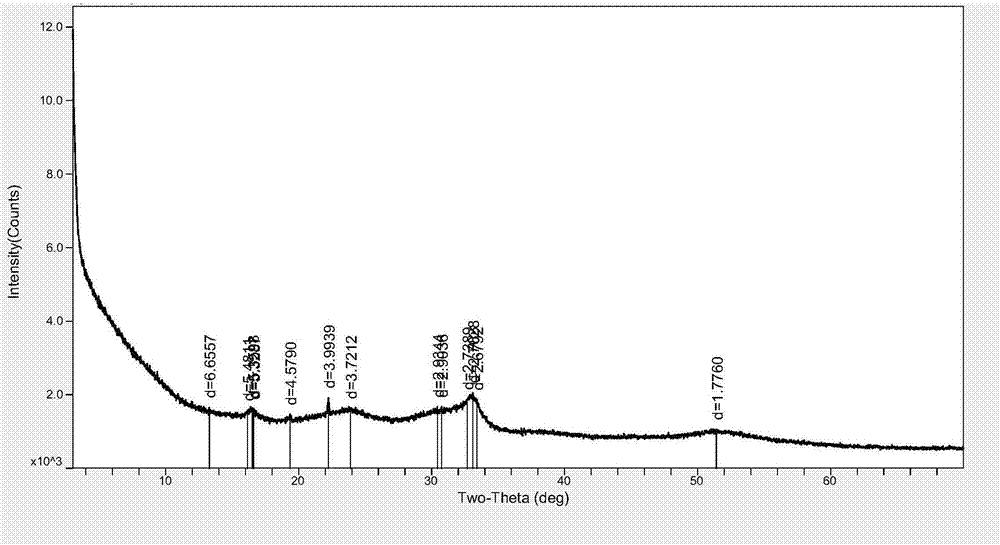

[0062] 5) Dry the solid obtained by centrifugation at 60°C, weigh 0.4568 kg, and carry out subsequent characterization experiments, and the results are as follows Figure 4 , Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com