Mos tube parameter degradation circuit, test circuit and early warning circuit

A MOS tube and parameter degradation technology, applied in the field of monitoring, can solve the problems of reduced output signal accuracy, inability to accurately warn of MOS tube failure, and high device failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical means adopted by the present invention and the effects obtained, the technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and preferred embodiments.

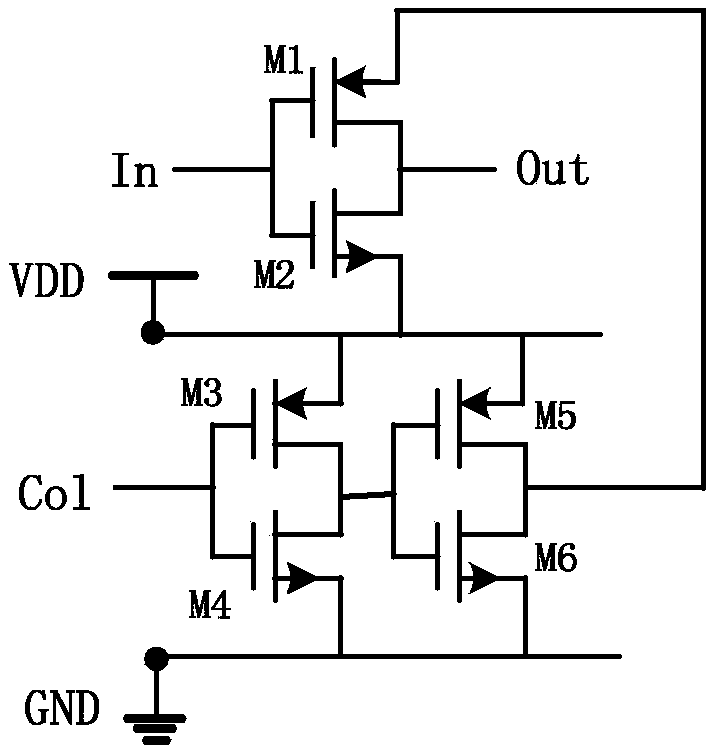

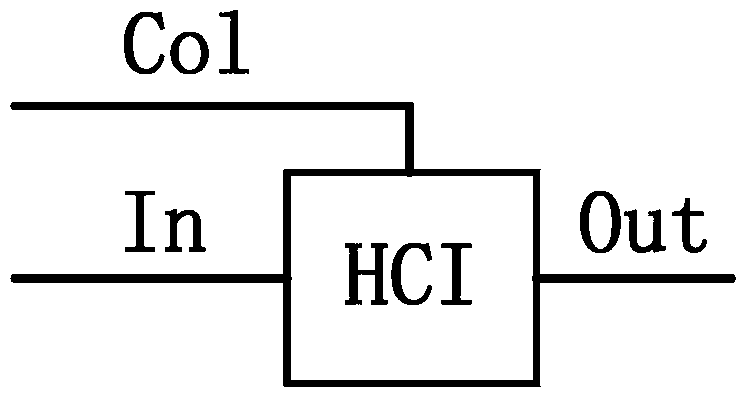

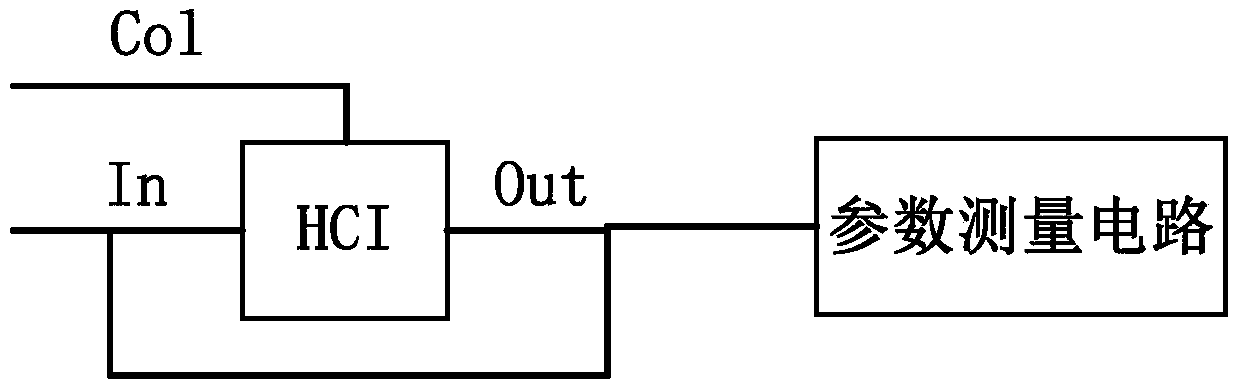

[0059] See figure 1 with figure 2 , a MOS transistor parameter degradation circuit, comprising an NMOS transistor M1 and a PMOS transistor M2; the gate of the NMOS transistor M1 is connected to the gate of the PMOS transistor M2, and the drain of the NMOS transistor M1 is connected to the PMOS transistor The drain of M2 is connected; the gate of the PMOS transistor M2 is connected to the power supply VDD; the source of the NMOS transistor M1 receives the control signal Col, and the control signal Col adopts a level signal. When the control signal Col is a high-level signal, the channel of the NMOS transistor M1 generates hot carriers; wherein, the process of injecting the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com