Camera assembly

A camera component and camera technology, applied to electrical components, parts of connecting devices, base/housing, etc., can solve problems such as abnormal function of body parts, display water ripples, display flickering, etc., to facilitate miniaturization design and improve sealing Sexuality, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other .

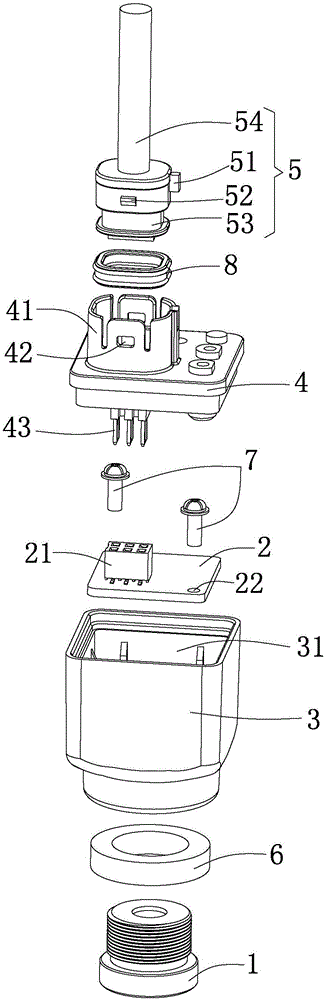

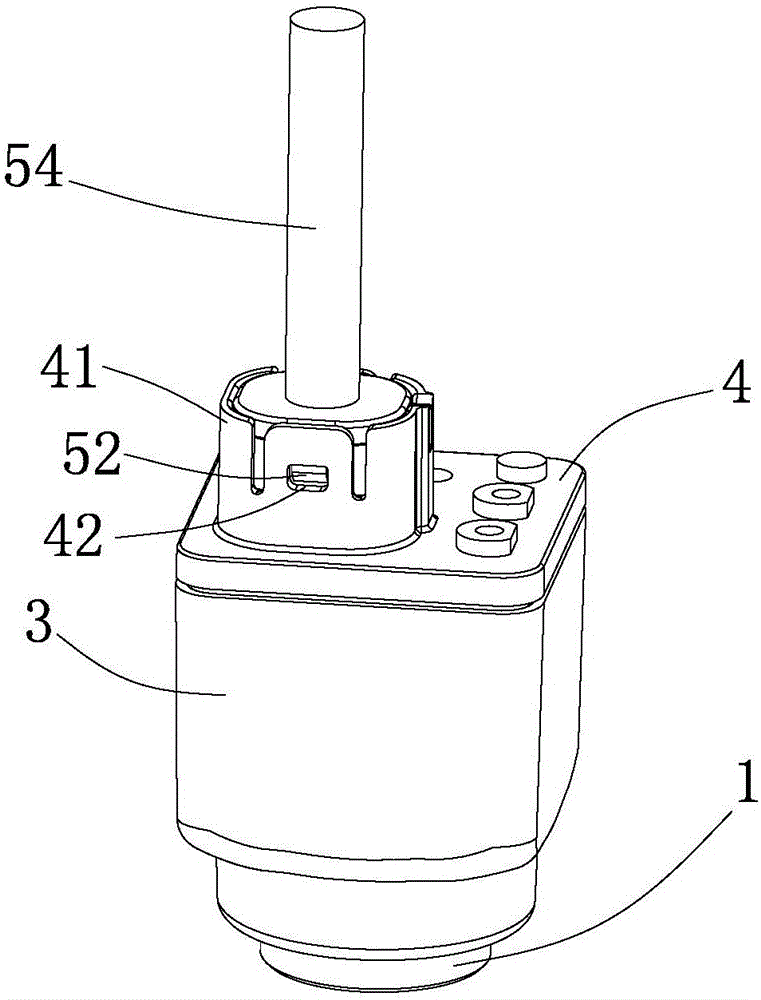

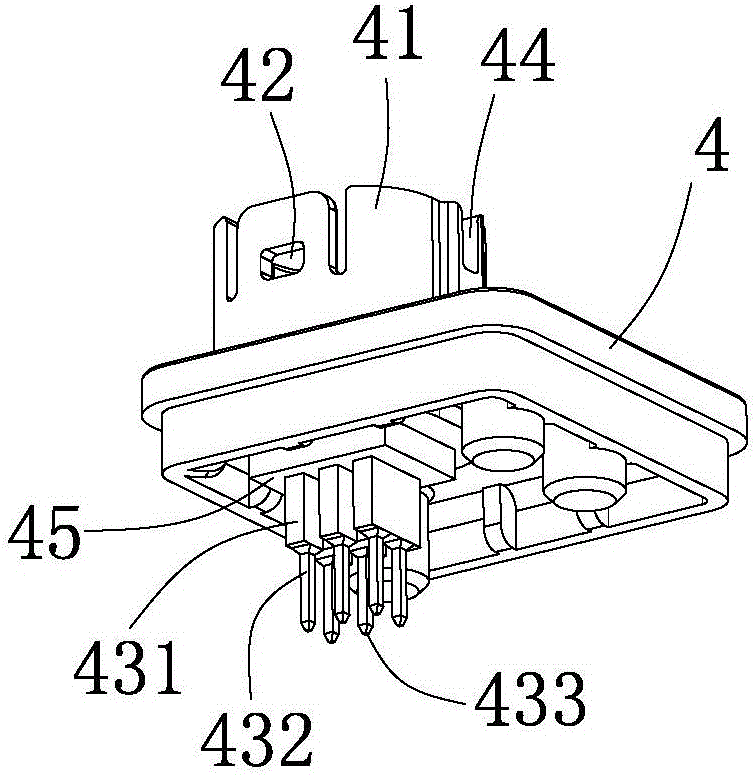

[0021] Such as figure 1 , figure 2 and Figure 5 As shown, the embodiment of the present invention provides a camera assembly, including a camera 1, a PCBA board 2, a housing 3 having a hollow cavity and openings at both ends, and a shell for closing the opening 31 at the first end of the housing 3 Cover 4 and harness 5.

[0022] The PCBA board 2 is accommodated in the hollow cavity of the housing 3, and the camera 1 is installed at the second end opening (not labeled) of the housing 3 and is electrically connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com