A tool for automatic intermodulation testing of radio frequency coaxial jumper components

A radio frequency coaxial, automatic testing technology, applied in the direction of measuring devices, measuring device shells, measuring electronics, etc., can solve the problems of delaying test time, reducing work efficiency, time-consuming and labor-intensive, etc., and achieves rapid response, simple structure, and exhaust treatment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

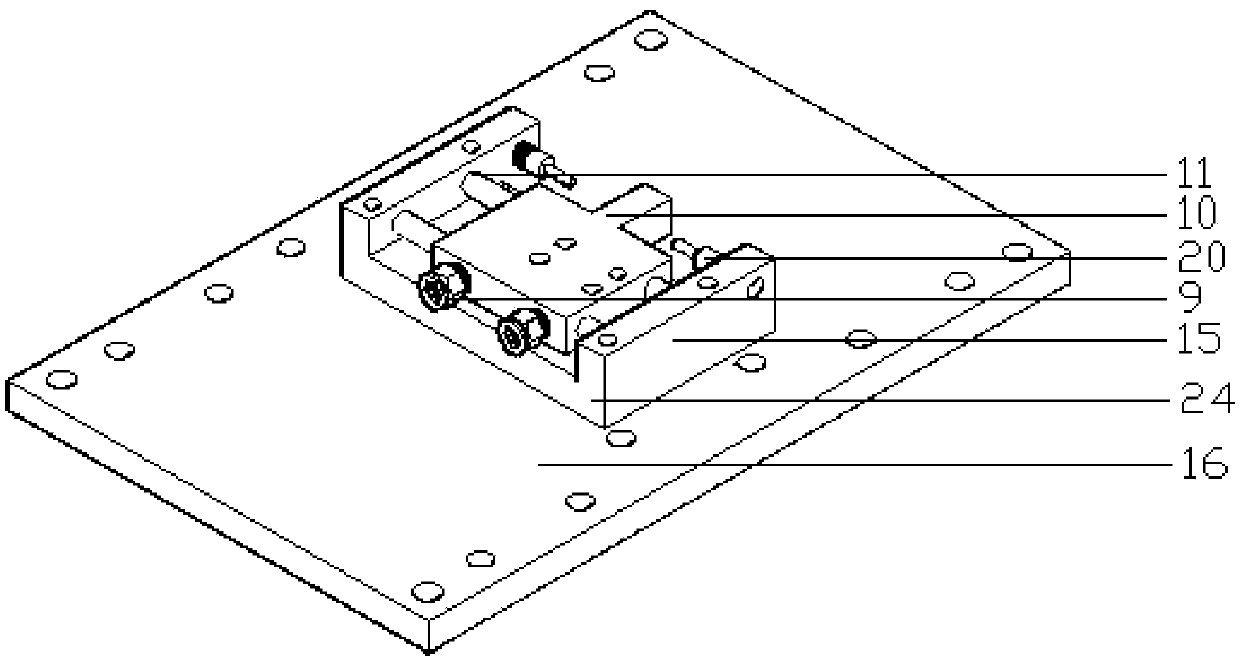

[0035] Such as Figure 1 to Figure 3 , an automatic test tool for intermodulation of radio frequency coaxial jumper components, which includes a mounting base 16, an axial pneumatic slide 15, a supporting plate A17, a cylinder 18, a supporting plate B12, a support frame A7, a positioning block seat 21, Displacement sensor 22, slide table cylinder 19, claw 5, positioning block 4, fixed frame 2; Described installation base plate 16 is in order to carry the whole device; Described axial pneumatic slide table 15 is installed on the base plate 16, and its cylinder body 10 It can move axially along the piston rod 11, and the supporting plate A17 is installed above the cylinder body 10 of the axial pneumatic slide table 15. Driven by the axial pneumatic sliding table 15, the supporting plate A17 can move along the guide post 13, and the guide post 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com