Method for detecting volatiles residue in hot-melt adhesive for cigarettes

A technology of volatile components, hot melt adhesive for cigarettes, applied in the field of tobacco analysis, to achieve the effects of accurate operation, simple and convenient method, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

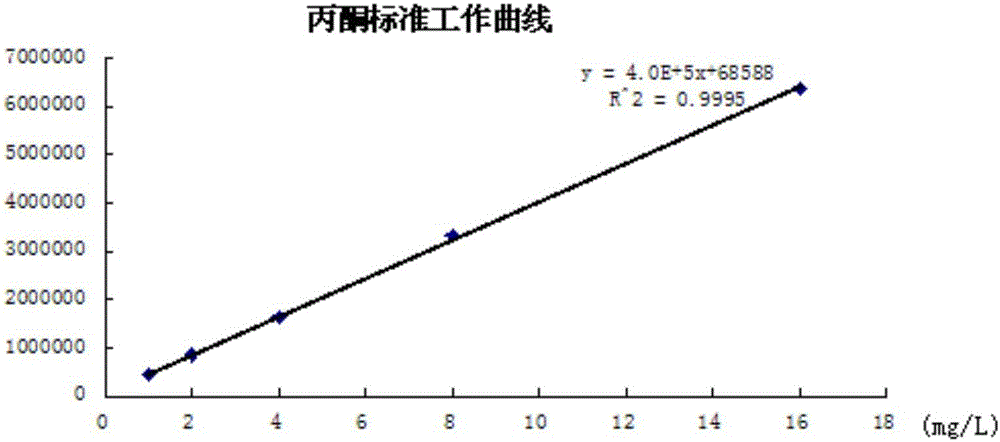

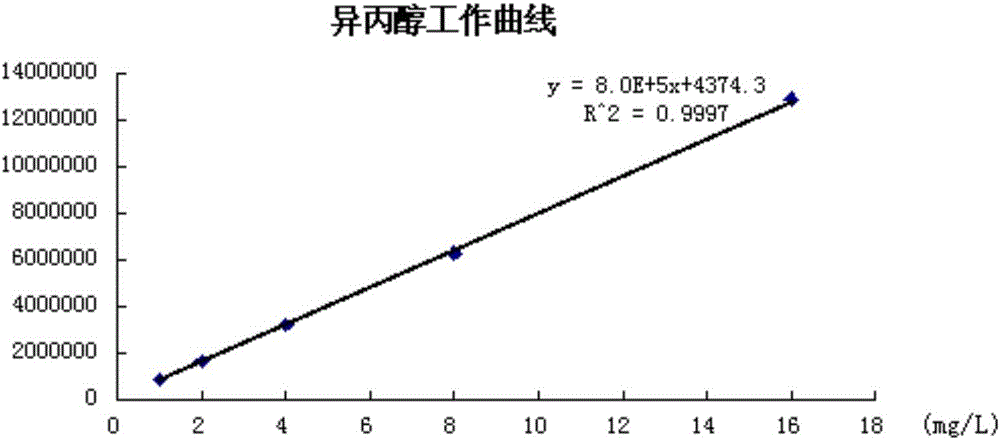

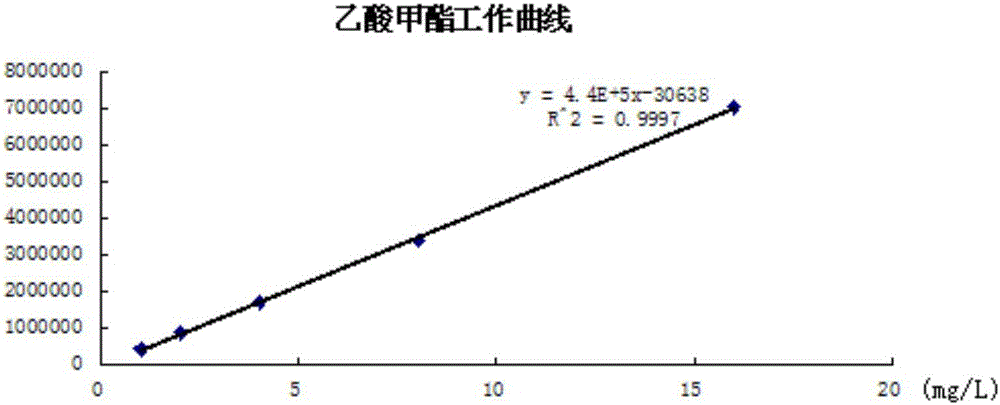

[0025] Weigh 0.0500g of acetone, isopropanol and methyl acetate standard products respectively, place them in a 1000mL volumetric flask, and dilute to the mark with chromatographically pure dimethylformamide, and this solution is the mixed standard stock solution. Accurately pipette 2mL, 4mL, 8mL, 16mL, and 32mL of the mixed standard stock solutions, place them in 100mL volumetric flasks, and dilute to the mark with chromatographically pure dimethylformamide to obtain a series of standard working solutions. Concentrations of the prepared serial mixed standard solutions are: 1mg / L, 2mg / L, 4mg / L, 8mg / L, 16mg / L.

[0026] Cut up the hot melt adhesive sample A, weigh 0.2000g and place it in a headspace bottle, accurately add 2mL of dimethylformamide, and analyze it by headspace-gas chromatography-mass spectrometer. The headspace conditions are: sample bottle equilibrium temperature: 120°C, sample loop temperature: 140°C, transfer line temperature: 180°C; sample vial equilibration t...

Embodiment 2

[0032] As described in Example 1, select another hot melt adhesive sample B, attached Figure 5 It is the chromatogram of hot melt adhesive sample B for cigarettes. The sample was measured twice, and the average value was obtained to obtain that the acetone content in sample B was 12.94 mg / L, the isopropanol content was 7.78 mg / L, and the methyl acetate content was 9.33 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com