An hourglass spring and a method for enhancing lateral stability of a vehicle

A technology of hourglass springs and bosses, applied in the direction of relative movement between the chassis and the bogie, low internal friction springs, springs/shock absorbers, etc., to achieve strong nonlinear characteristics, improve lateral stability, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

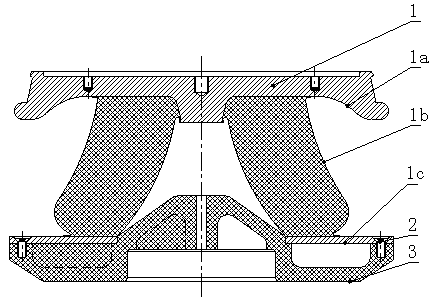

[0025] The accompanying drawing shows a schematic diagram of a specific example of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Please refer to figure 1, an hourglass spring, comprising an hourglass spring vulcanized part 1, a hexagon socket head screw 2 and a support seat 3; the hourglass spring vulcanized part consists of an upper end plate 1a, a rubber 1b and a bottom plate 1c. The hourglass spring is mainly composed of an hourglass spring vulcanized part 1 and a support seat 3 connected by a hexagon socket head screw 2. Hourglass spring vulcanized parts are mainly composed of upper end plate, rubber and bottom plate vulcanized. The side of the upper end plate in contact with the rubber is designed with a rounded truncated boss one. The junction between the side of the boss one and the lower surface of the upper end plate is a smooth transition. The side of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com