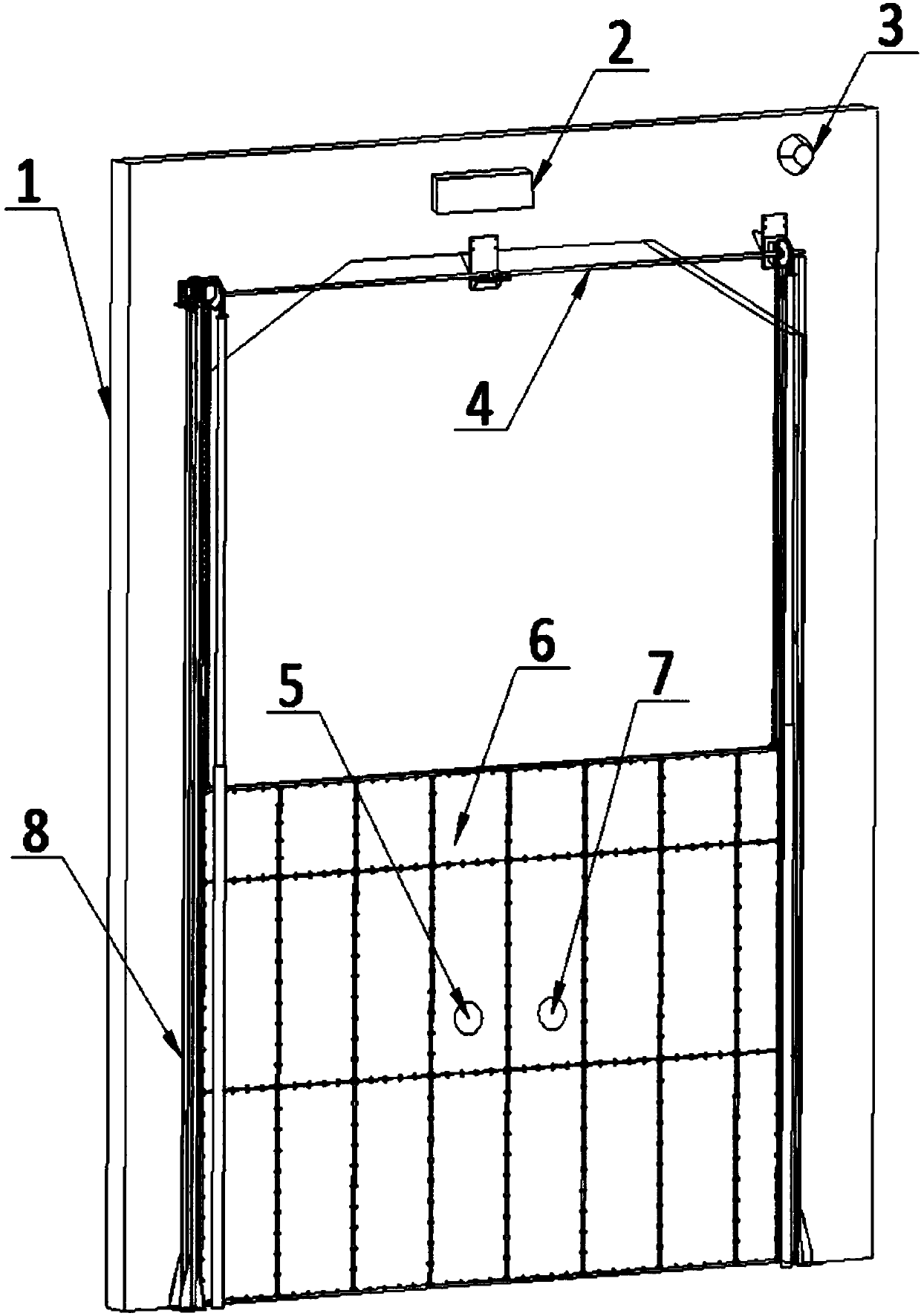

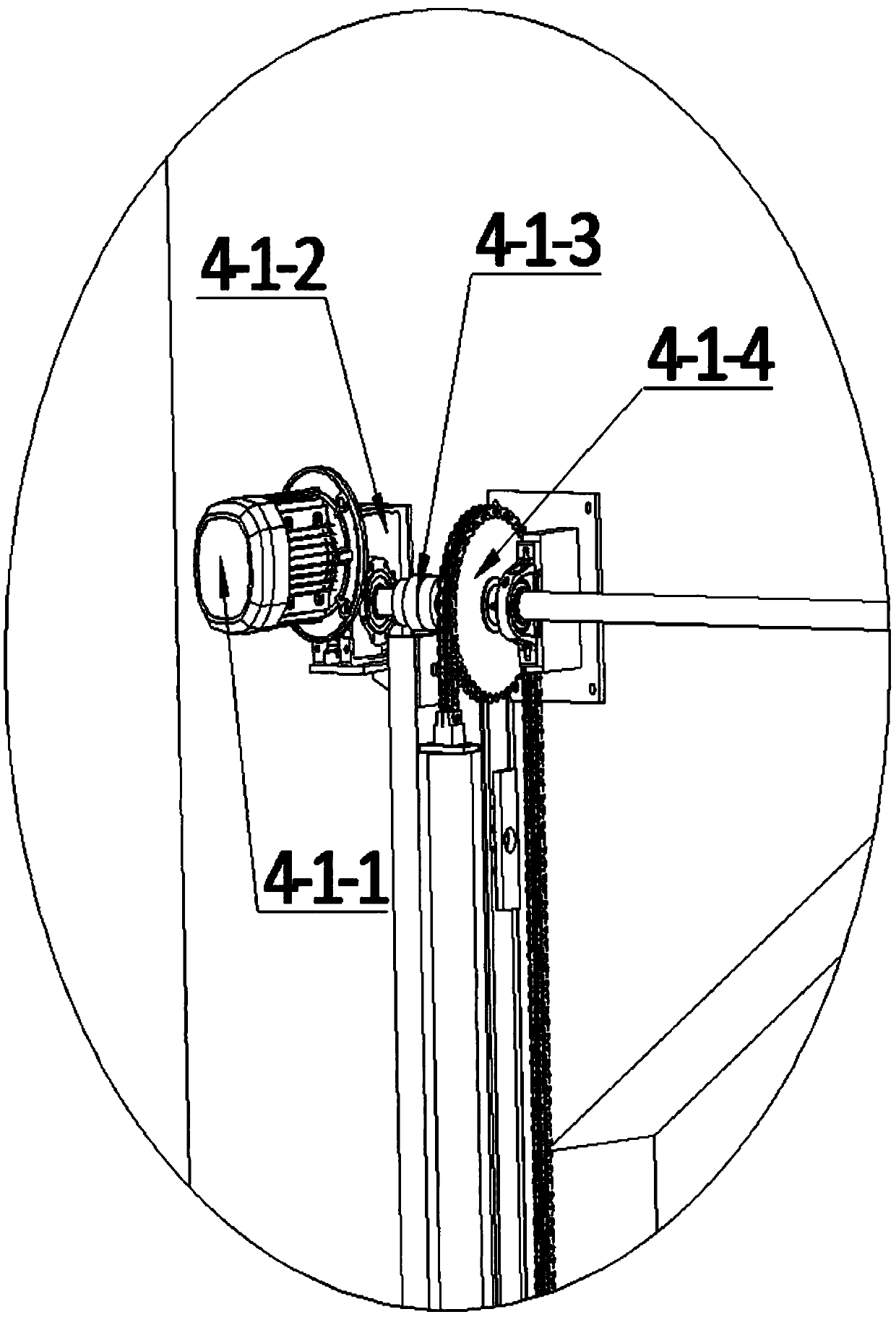

An automatic opening and closing explosion-proof and fire-proof safety door device

An automatic opening and closing, safety door technology, applied in fire doors, door leaves, windows/doors, etc., can solve the problems of heavy weight, furnace energy waste, heat loss, etc., to achieve easy transportation and installation, high degree of automation, and manufacturing costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Manufacture protective plate 6 of the present invention according to the following steps, and in parts by weight:

[0053] Step 1: Add 3100 parts of ultrapure water with a conductivity of 4.87 μS / cm into the reactor, start the stirrer in the reactor at a speed of 94 rpm, and start the heating pump to raise the temperature in the reactor to 84 °C; Add 140 parts of tert-butyl 1-(4-bromophenyl)piperidin-4-ylcarbamate, 53 parts of (5-amino-2-(4-isopropylpiperazin-1-yl)phenyl)methanol , 33 parts of ethyl 1-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidin-4-ylcarbamate, Stir until completely dissolved, adjust the pH value to 4.29, adjust the stirrer speed to 140 rpm, the temperature is 145 ° C, and the esterification reaction is 18 hours;

[0054] Step 2: Take 86 parts of [4-[[3-(3-azidine)-2-pyrazine]oxy]phenyl]-1H-benzimidazol-2-yl ketone, 4-(4 -57 parts of methyl (4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidine-1-carboxylate were pulverized,...

Embodiment 2

[0059] Manufacture protective plate 6 of the present invention according to the following steps, and in parts by weight:

[0060] Step 1: Add 3650 parts of ultra-pure water with a conductivity of 5.78 μS / cm into the reactor, start the stirrer in the reactor at a speed of 128 rpm, and start the heating pump to raise the temperature in the reactor to 104 °C; Add 212 parts of tert-butyl 1-(4-bromophenyl)piperidin-4-ylcarbamate, 113 parts of (5-amino-2-(4-isopropylpiperazin-1-yl)phenyl)methanol , 79 parts of ethyl 1-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidin-4-ylcarbamate, Stir until completely dissolved, adjust the pH value to 5.46, adjust the stirrer speed to 172 rpm, the temperature is 185 ° C, and the esterification reaction is 23 hours;

[0061] Step 2: Take 139 parts of [4-[[3-(3-azidine)-2-pyrazine]oxy]phenyl]-1H-benzimidazol-2-yl ketone, 4-(4 -119 parts of methyl (4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidine-1-carboxylate were pulve...

Embodiment 3

[0066] Manufacture protective plate 6 of the present invention according to the following steps, and in parts by weight:

[0067] Step 1: Add 4,200 parts of ultrapure water with a conductivity of 6.69 μS / cm into the reactor, start the stirrer in the reactor at a speed of 162 rpm, and start the heating pump to raise the temperature in the reactor to 124 °C; Add 285 parts of tert-butyl 1-(4-bromophenyl)piperidin-4-ylcarbamate, 174 parts of (5-amino-2-(4-isopropylpiperazin-1-yl)phenyl)methanol 125 parts of ethyl 1-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidin-4-ylcarbamate, Stir until completely dissolved, adjust the pH value to 6.64, adjust the stirrer speed to 212 rpm, the temperature is 226 ° C, and the esterification reaction is 28 hours;

[0068] Step 2: Take 193 parts of [4-[[3-(3-azidine)-2-pyrazine]oxy]phenyl]-1H-benzimidazol-2-yl ketone, 4-(4 -181 parts of methyl (4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)piperidine-1-carboxylate were pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com