Lubricating oil atomizing system of sewing machine transmission chamber

A technology of atomization system and transmission chamber, applied in the field of sewing machines, can solve the problems of increased noise, physical influence, unreasonable design of lubrication system, etc., and achieve the effect of noise reduction, effective lubrication and good atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

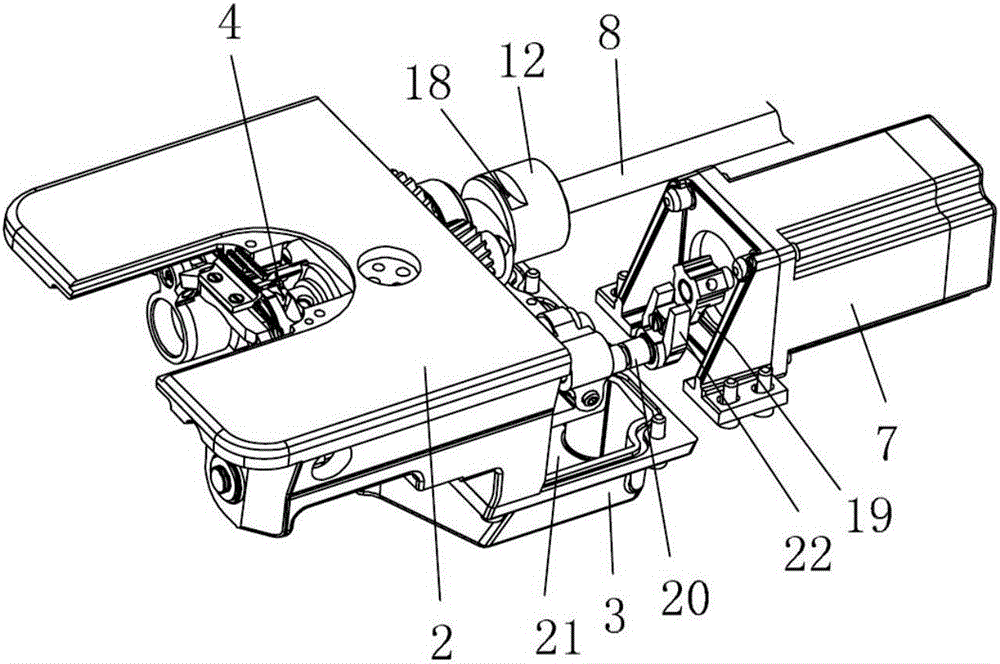

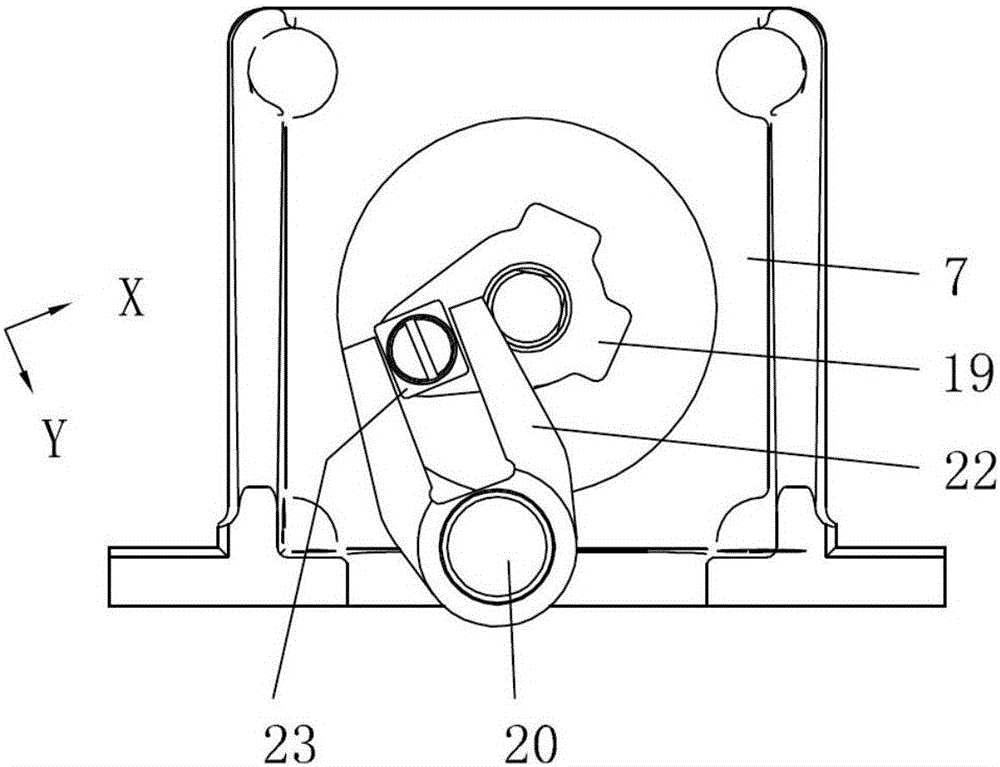

[0028] The lubricating oil atomization system of the transmission room of the sewing machine is provided with a transmission room in the lower part of the sewing machine housing. The tooth lifting shaft 8, the swing tooth shaft 28 and the rotary hook shaft 27 extend into the transmission chamber; the tooth lifting shaft 8 passes through the first transmission mechanism Drive the swing tooth shaft 28 to reciprocate, the lifting shaft 8 drives the hook shaft 27 to rotate through the second transmission mechanism; an oil box is installed in the lower part of the transmission chamber, and an oil storage cavity is provided in the oil box, and the oil box seals the transmission chamber. The lower end surface is characterized in that an oil suction channel is arranged in the transmission chamber, and when a certain amount of oil is accumulated in the oil storage cavity, the lower end of the oil suction channel is immersed in the oil; the oil delivery mechanism transports the oil in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com