A kind of preparation method of layered structure thermal barrier coating

A thermal barrier coating, layered structure technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of low coating life, difficult thermal conductivity, reduction, etc. Longevity and the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] This embodiment provides a method for preparing a layered structure thermal barrier coating, which includes the following steps:

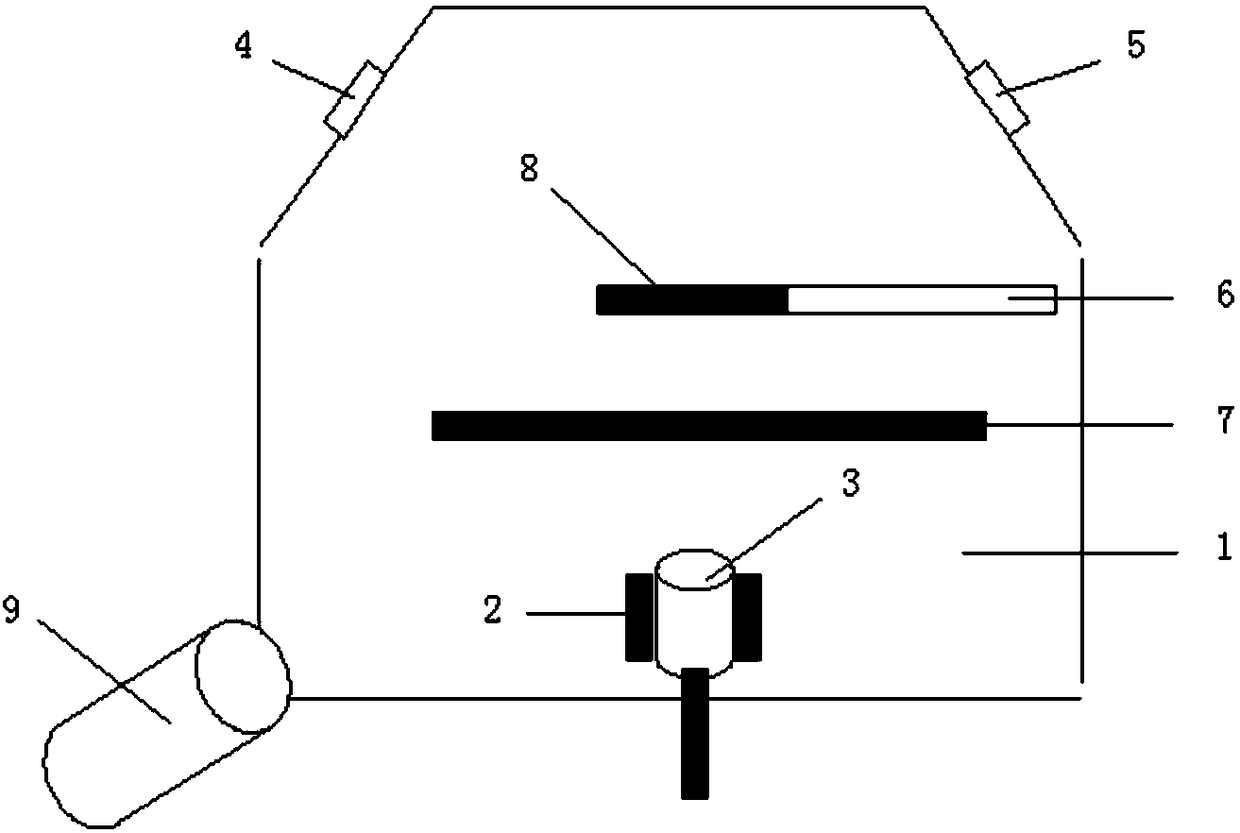

[0041] (1) Put the zirconia evaporation material rod 3 partially stabilized by yttrium oxide into the crucible 2 of the vacuum chamber 1, put the ion source target material titanium into the ion source 9, and evacuate the vacuum chamber 1 to 1×10 -2 Below Pa;

[0042] (2) Move the workpiece 8 directly above the evaporation material rod 3, set the rotation speed of the horizontal axis 6 to 12 rpm, and move the baffle plate 7 between the evaporation material rod 3 and the workpiece 8;

[0043] (3) Use the electron gun 4 to pre-evaporate the evaporation material rod 3, and adjust the electron beam current to 1.8A. When the surface of the evaporation material rod 3 is completely melted and boils, reduce the beam current to 0.3A;

[0044] (4) Preheat the workpiece 8 with the electron gun 5, and adjust the electron beam current to 0.1A;

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com