Method for producing potassium magnesium sulfate fertilizer and manganese sulfate from manganese-containing fly ash

A technology of potassium magnesium sulfate fertilizer and manganese sulfate, which is applied in the direction of manganese sulfate, can solve the problems of environmental secondary pollution, environmental pollution, and low consumption, and achieve significant economic value and the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

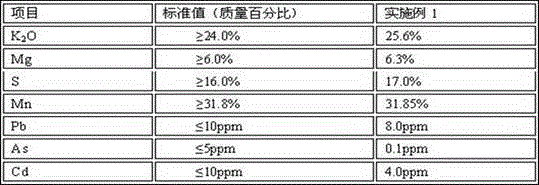

Embodiment 1

[0022] A method of producing potassium magnesium sulfate fertilizer and manganese sulfate with manganese-containing dust removal ash:

[0023] Select 20 tons of manganese-containing dust removal ash and 40 tons of water; the composition of manganese-containing dust removal dust is (mass percentage): manganese 15.8%, potassium oxide 18.3%, magnesium 7.3%, and the remaining components are Pb, As, Cd, Ni, Co heavy metals.

[0024] The preparation method is as follows:

[0025] (1) Ball milling: Put manganese-containing dedusting ash into a ball mill and add water to wet mill. The particle size of the material after ball milling is 98% of the total material by mass after passing through a 100-mesh sieve;

[0026] (2) Fertilizer immersion: put the ball-milled material in a leaching tank, and feed sulfur dioxide gas into the material while stirring. After 3 hours, the pH value of the material reaches 5.0, and stop supplying sulfur dioxide gas;

[0027] (3) Solid-liquid separation ...

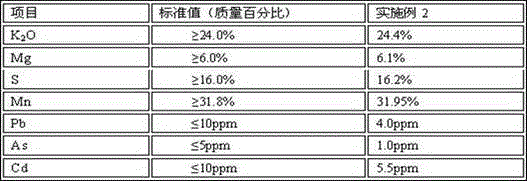

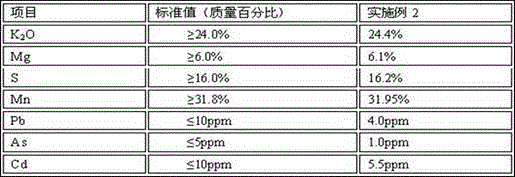

Embodiment 2

[0036] A method of producing potassium magnesium sulfate fertilizer and manganese sulfate with manganese-containing dust removal ash:

[0037] Select 15 tons of manganese-containing dust removal ash and 32 tons of water; the composition of manganese-containing dust removal dust is (mass percentage): manganese 19.2%, potassium oxide 15.6%, magnesium 5.8%, and the remaining components are Pb, As, Cd, Ni, Co heavy metals.

[0038] The preparation method is as follows:

[0039] (1) Ball milling: Manganese-containing dedusting dust is wet-milled in a ball mill with water, and the particle size of the material after ball milling is: the material passing through a 100-mesh sieve accounts for 99% of the total;

[0040] (2) Fertilizer immersion: put the ball-milled material in a leaching tank, and feed sulfur dioxide gas into the material while stirring. After 2.5 hours, the pH value of the material reaches 5.0, and stop supplying sulfur dioxide gas;

[0041] (3) Solid-liquid separat...

Embodiment 3

[0050] A method of producing potassium magnesium sulfate fertilizer and manganese sulfate with manganese-containing dust removal ash:

[0051] Select 20 tons of manganese-containing dust removal ash and 41 tons of water; the composition of manganese-containing dust removal dust is (mass percentage): manganese 14.3%, potassium oxide 11.7%, magnesium 9.5%, and the remaining components are Pb, As, Cd, Ni, Co heavy metals.

[0052] The preparation method is as follows:

[0053] (1) Ball milling: add manganese-containing dust to the ball mill and add water to wet mill. The particle size of the material after ball milling is: the material passing through the 100-mesh sieve accounts for 98% of the total;

[0054] (2) Fertilizer immersion: put the ball-milled material in a leaching tank, and feed sulfur dioxide gas into the material while stirring. After 3.5 hours, the pH value of the material reaches 5.0, and stop supplying sulfur dioxide gas;

[0055] (3) Solid-liquid separation (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com