A smoke alarm assembly line

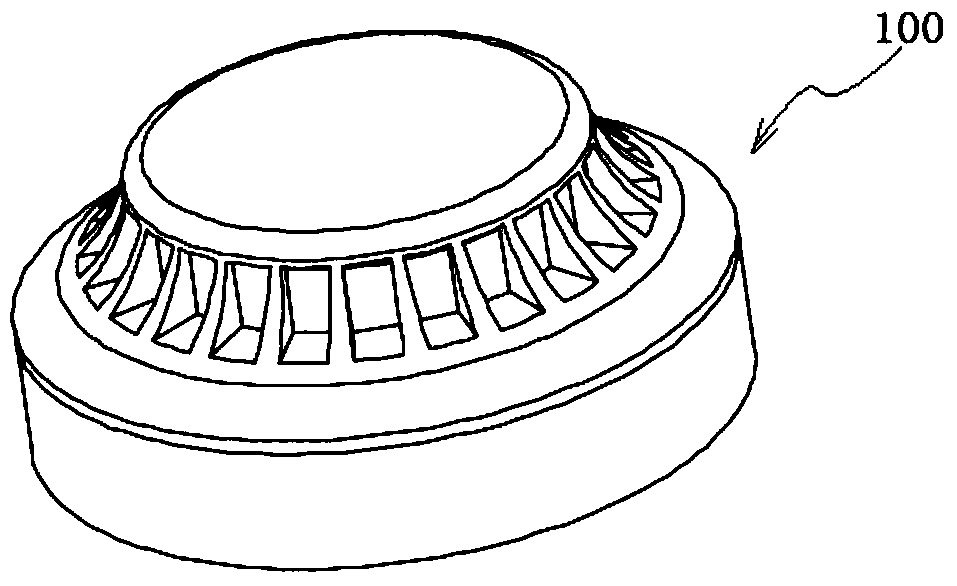

A smoke alarm and production line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and poor product quality, and achieve the effects of reducing use costs, simple structure, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

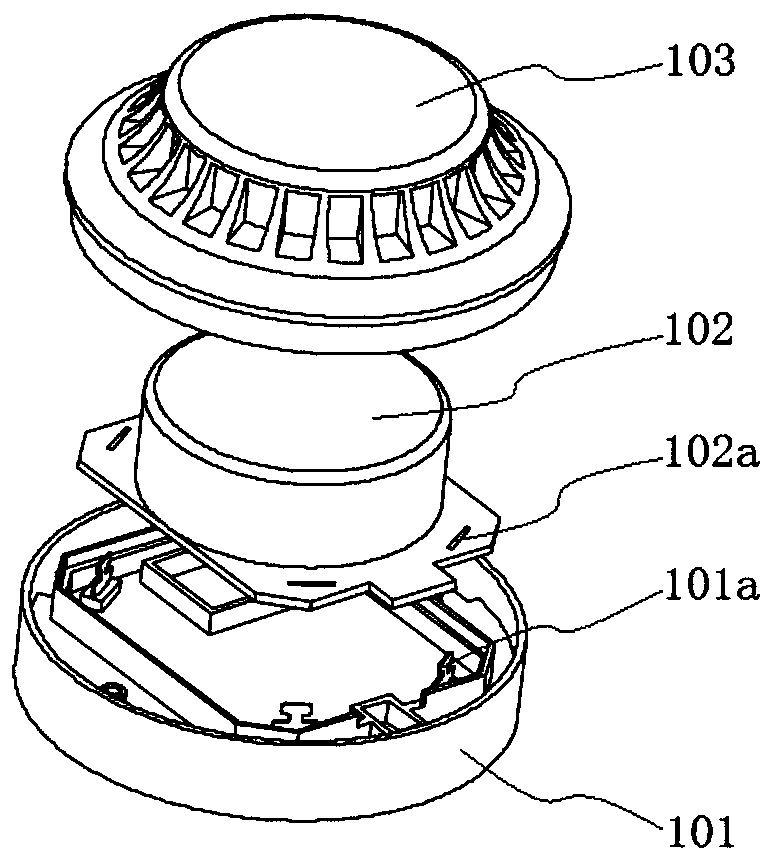

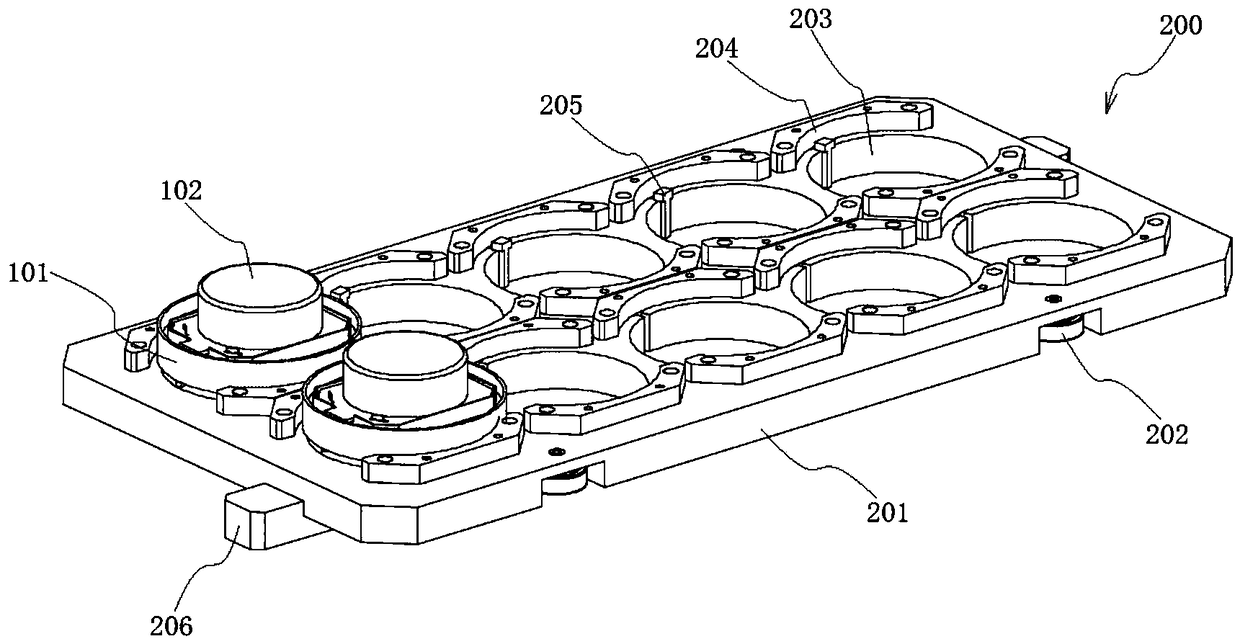

[0054] combine Figure 5 As shown, a smoke alarm assembly production line in this embodiment includes a conveying line 1, and the conveying line 1 has a base installation station 1-1, an integrated circuit component installation station 1-2, and a foot screwing station 1-1 in sequence. 3. Electrical performance testing station 1-4, upper cover installation station 1-5 and upper cover pressing station 1-6, foot screwing station 1-3 is equipped with screwing device 2, electrical performance testing station 1 -4 is equipped with a detection device 3, and the cover pressing station 1-6 is provided with a cover pressing device 4, and the base installation station 1-1, the integrated circuit component installation station 1-2 and the upper cover installation station 1-5 can be manually installed, and the components of the smoke alarm 100 can be conveyed or transported to each station by a conveyor belt. The conveying line 1 is provided with a positioning pallet 200 for installing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com