Synchronous hot-pressing-laser welding resistance hot pressing device

A technology of hot pressing device and laser welding, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that high-efficiency welding effect cannot be achieved, and preheating and pressure cannot be applied at the same time, so as to reduce air holes and improve Absorption rate, effect of reducing laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

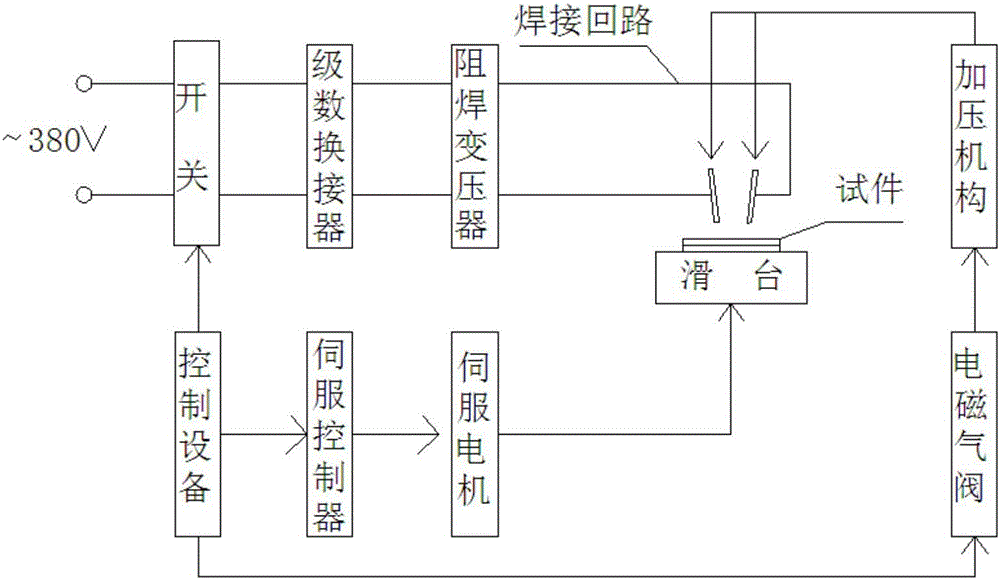

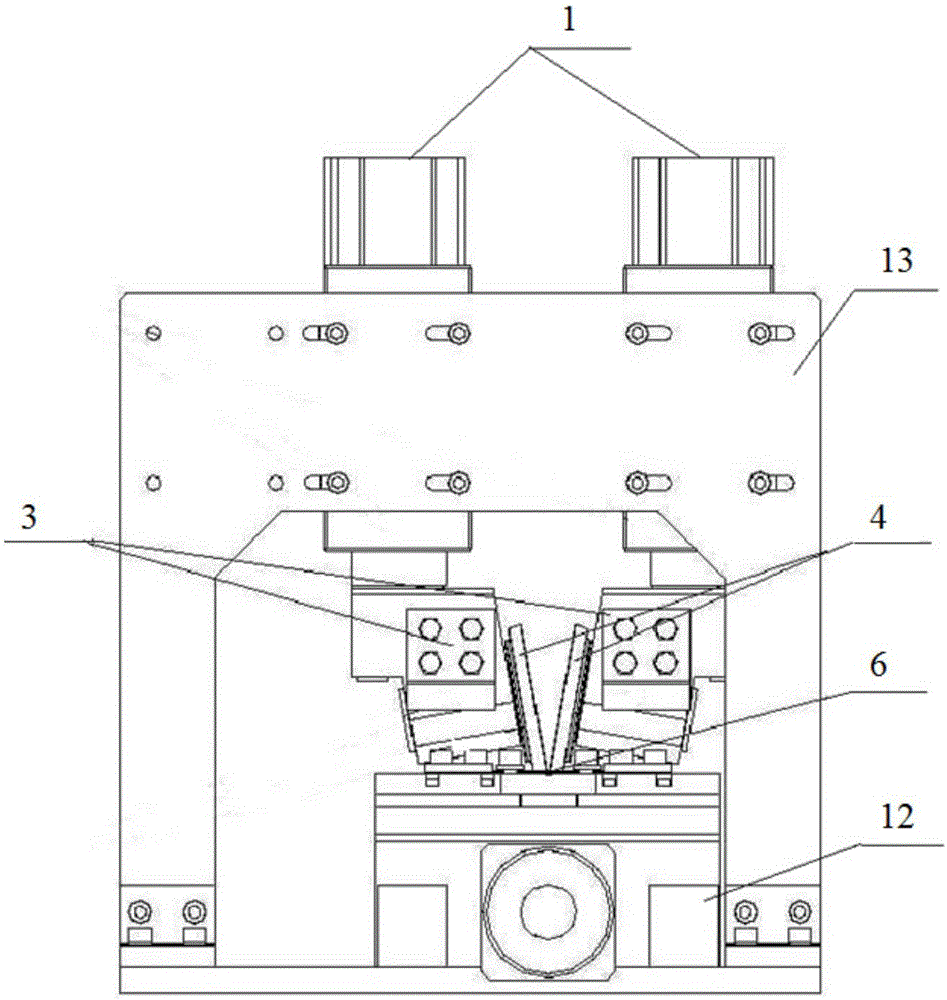

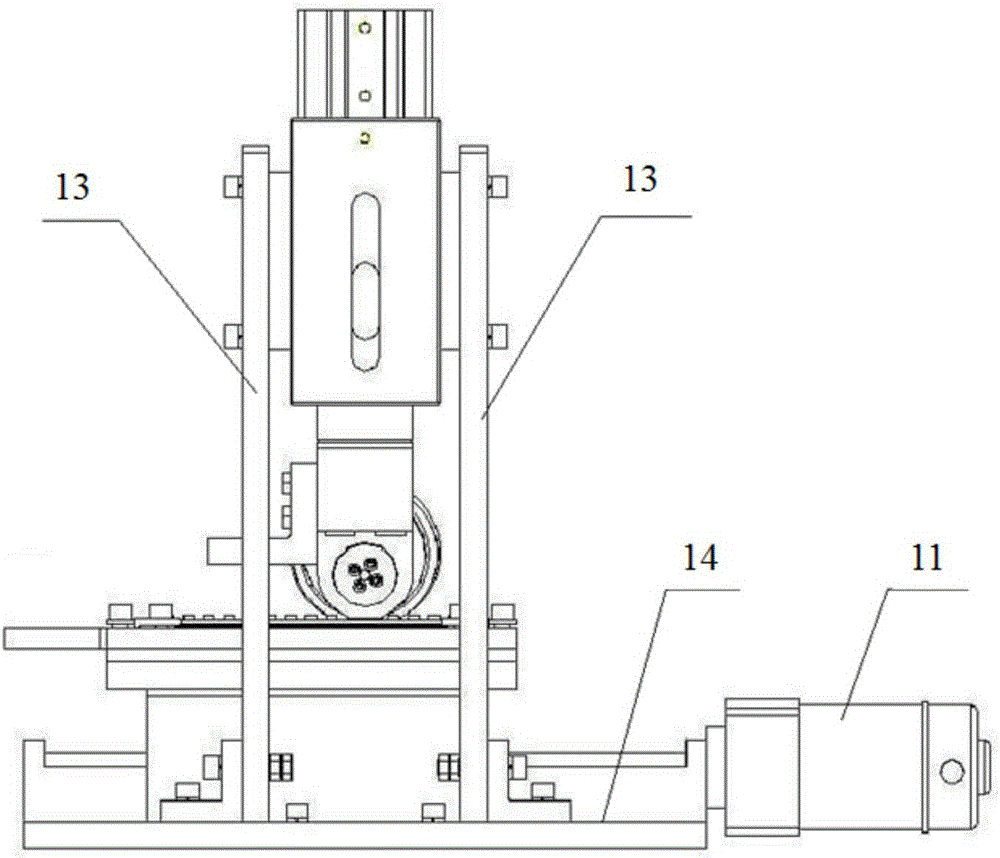

[0031] Such as Figure 2-8 As shown, a resistance thermocompression device for synchronous thermocompression-laser welding of the present invention is mainly used in single-sided welding, including a one-way 380V power supply, control equipment, series switch, welding resistance transformer, welding workbench, The pressurizing mechanism, the electrode arm group and the waterway module, the power supply, the series switch, the welding resistance transformer and the electrode arm group are electrically connected in sequence to form a welding circuit, and one control terminal of the control device is connected to the series switch The input terminal is connected, the series switch adopts a thyristor, the control device controls the conduction angle of the thyristor to adjust the welding current, and the primary end of the welding resistance transformer is adjusted by the series changer to determine the welding resistance transformer ratio.

[0032]The welding workbench includes ...

Embodiment 2

[0037] Such as Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 is that the setting of the electrode arm and the connection of the welding resistance transformer are different. A resistance hot pressing device for synchronous hot pressing and laser welding of the present invention is mainly used for double-sided welding, including One-way 380V power supply, control equipment, series switch, welding resistance transformer, welding workbench, pressurizing mechanism, electrode arm group and waterway module, the power input terminal is connected with a switch for controlling on-off. The connection of the electrode arm of this embodiment is different from Embodiment 1. During double-sided welding in this embodiment, the left electrode arm of the resistance welding head 3, pressurized cylinder 1 and guide sleeve 2 on the left is translated to the left In the new position on the side, the right electrode arm is removed and decomposed, and the right resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com