Double-layer hollow cylinder fusion mold shell structure for heat-resistant alloy vacuum suction casting technology

A high-temperature-resistant alloy and vacuum suction casting technology, applied in the field of precision casting, can solve problems such as vacuum suction casting of difficult-to-resistance high-temperature alloys, dangerous accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

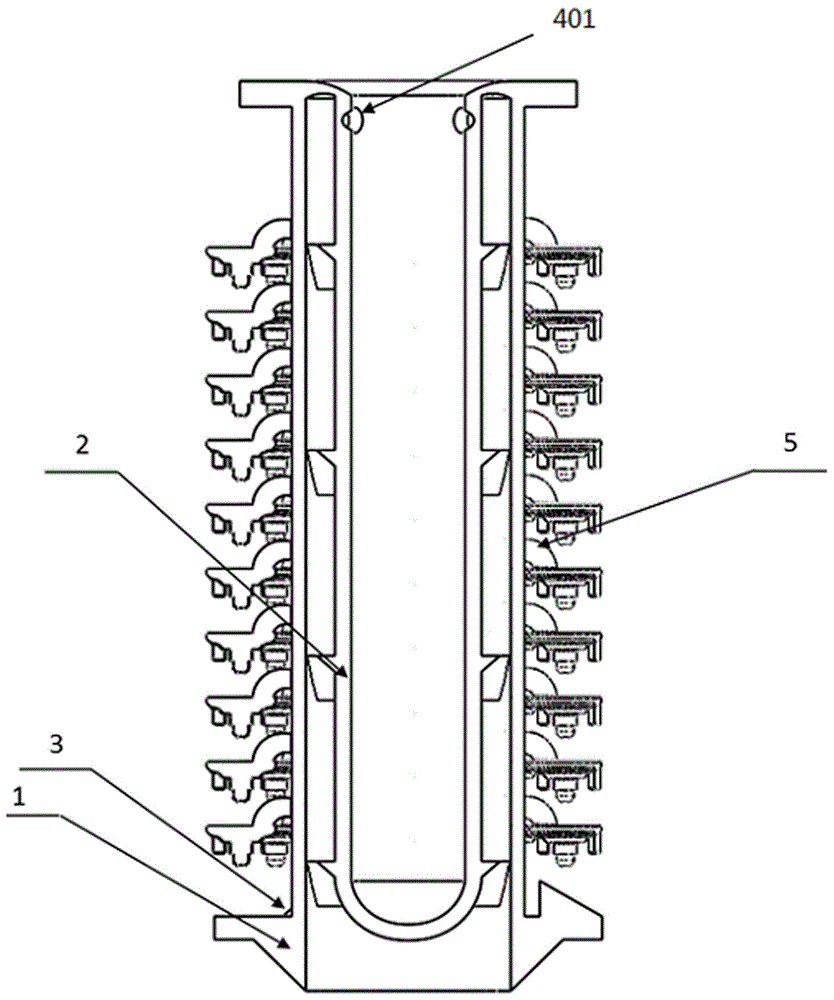

[0024] The formwork structure is a double-layer structure, the outer layer is an outer shell, and the inner layer is a hollow cylinder structure. The hollow cylinder is connected to the outer shell through an intermediate connector; a molten steel circulation is provided between the hollow cylinder and the outer shell. The steel liquid flow channel is connected with the formwork casting on the outer side of the outer shell through the runner, the upper end of the formwork structure is provided with a platform, and the lower end of the formwork structure is provided with a reinforcement structure.

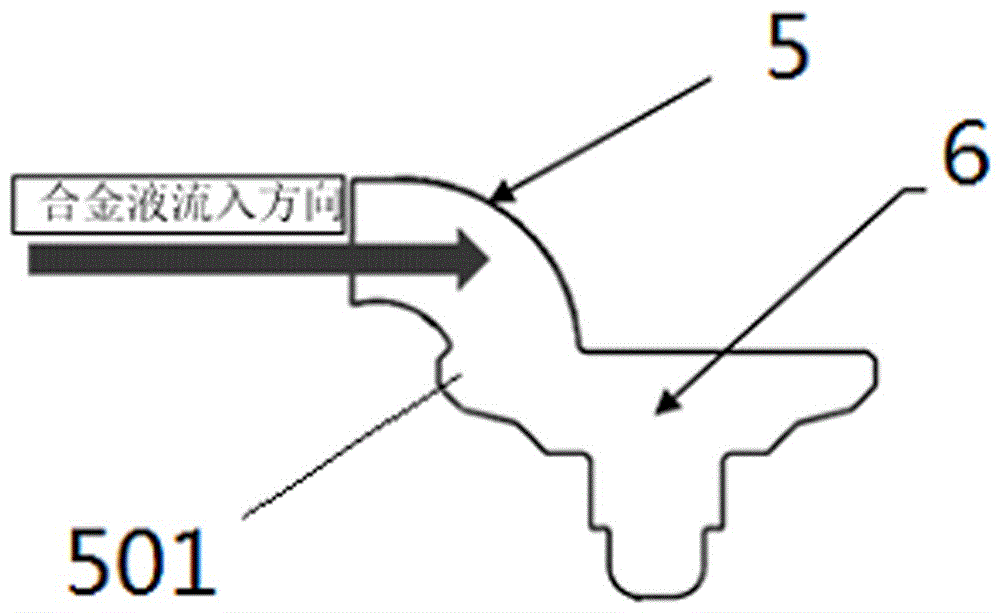

[0025] There are 12 intermediate connectors evenly distributed between the inner layer and the outer layer, and the intermediate connectors are arranged in groups of 3 in the steel liquid flow channel between the inner layer and the outer layer. The distance between them is equal. The intermediate connector has a sheet-like structure, with a bending groove in the middle, and the int...

Embodiment 2

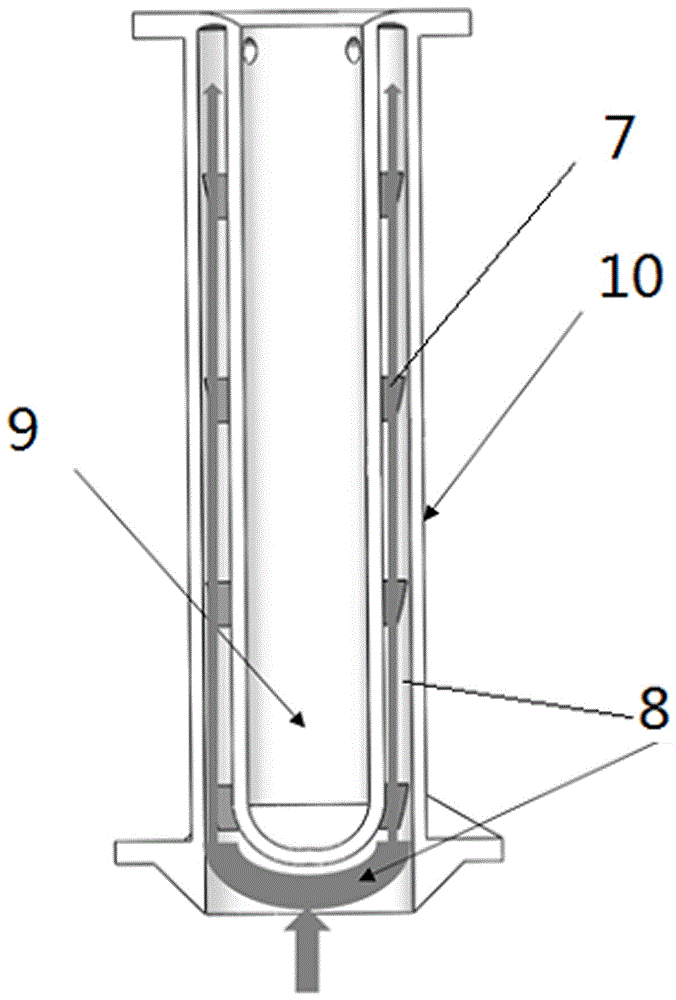

[0028] The mold shell structure is a double-layer structure, the outer layer is an outer shell, and the inner layer is a hollow cylinder structure, and the hollow cylinder is connected with the outer shell through an intermediate connector; the hollow cylinder is designed for the rise and fall of the alloy solution and the gas emissions. To ensure the smooth rise of the alloy solution in the filling stage of the casting and the rapid return of the alloy solution in the hollow through the inner alloy solution in the pressure relief stage.

[0029] There is a steel liquid flow channel between the hollow cylinder and the outer shell, and the steel liquid flow channel is connected with the formwork casting on the outside of the outer shell through the runner. The upper end of the formwork structure is provided with a platform, and the lower end of the formwork structure is provided with a reinforcement structure. Formwork castings are distributed around the formwork structure, an...

Embodiment 3

[0031] There are 6-20 intermediate connectors evenly distributed between the inner layer and the outer layer. The intermediate connectors are in a sheet structure, with a bending groove in the middle, and the intermediate connectors are arranged obliquely between the inner and outer layers. The angle range between the intermediate connector and the outer layer is 20-50 degrees, and the thickness ratio between the inner layer and the outer layer is 1:0.8-1.2, thus forming a double-layer hollow cylinder structure, the purpose of which is to reduce the charging The amount of alloy solution needed in the molding stage and the best temperature control effect. The bottom of the hollow cylinder is provided with a semicircular structure, and the semicircular structure is provided with a flow channel control part. The beginning of the stream channel.

[0032] The purpose of designing the stiffener structure at the bottom of the formwork is to improve the strength of the formwork. Ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com