Processing method of concentrated dendrobium candidum leaf tea juice

A technology of Dendrobium candidum and tea concentrated juice, which is applied in the field of processing Dendrobium candidum leaf tea concentrated juice, can solve the problems of resource waste and underutilized leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Wash 40 kg of fresh leaves of Dendrobium candidum in tap water, drain, soak in 0.05% (w / v) pectinase dilution solution for 45 minutes, drain and wither in hot air for 8 hours until the withering liquid The moisture content is 58%; the withered leaves are fixed with a hot air cleaning machine, the temperature of the cleaning treatment is 240°C, and the moisture content of the fixed leaves is 48%; after the leaves are cooled, they are kneaded with a 40-type kneading machine for 60 minutes until the iron sheet Dendrobium leaf juice overflows; knead the leaves for extraction (65°C, 90 minutes, leaf water ratio 1:5) treatment, the amount of cellulase in the extract is 0.1% (w / v), to obtain Dendrobium officinale leaf extract juice 175 kg. Use NaOH solution to adjust the pH value of the extract juice of Dendrobium officinale to 6.0, then use a microfiltration membrane (0.2 μm pore size) to filter, and then use a reverse osmosis membrane to concentrate the extract juice to a co...

Embodiment 2

[0028] Wash 60 kg of fresh Dendrobium officinale leaves in tap water, drain, soak in 0.01% (w / v) pectinase dilution solution for 90 minutes, drain and wither in natural wind for 72 hours until withering The water content of the liquid is 65%; the withered leaves are fixed with a hot air cleaning machine, the temperature of the cleaning treatment is 280 ° C, and the water content of the finished leaves is 52%; Leaf juice of Dendrobium officinale overflows; knead the leaves for extraction (45°C, 180 minutes, leaf water ratio 1:10), and add 0.05% (w / v) of cellulase in the extract to obtain Dendrobium officinale leaf extraction Juice 555 kg. Use NaOH solution to adjust the pH value of Dendrobium officinale leaf extract to 5.5, then filter it with a microfiltration membrane (0.2 μm pore size), and then use a reverse osmosis membrane to concentrate the extract juice to a concentrate with a solid content of 12°Brix . Finally, it is sterilized by UHT (135°C, 30s), and hot-filled int...

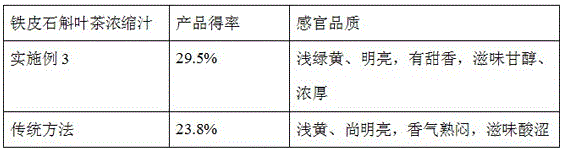

Embodiment 3

[0032] Wash 50 kg of fresh leaves of Dendrobium candidum in tap water, drain, soak in 0.2% (w / v) pectinase dilution solution for 30 minutes, drain and wither in a blowing environment for 48 hours until withering The moisture content of the liquid is 55%; the withered leaves are fixed with a hot air cleaning machine, the temperature of the cleaning treatment is 260°C, and the moisture content of the finished leaves is 50%; The leaves were extracted (55°C, 120 minutes, leaf-to-water ratio 1:7), and the amount of cellulase added to the extract was 0.01% (w / v) to obtain 305 kg of Dendrobium officinale leaf extract. Using Na 2 CO 3 Solution Adjust the pH value of Dendrobium candidum leaf extract to 5.8, then filter it with a microfiltration membrane (0.2 μm pore size), and then use a reverse osmosis membrane to concentrate the extract juice to a concentrate with a solid content of 15°Brix. Finally, it was sterilized by UHT (135°C, 30 s), and hot-filled into Dendrobium officinale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com